Zoran

freely admits to licking rocks

Member since September 2005

Posts: 880

|

Post by Zoran on Nov 17, 2006 20:41:55 GMT -5

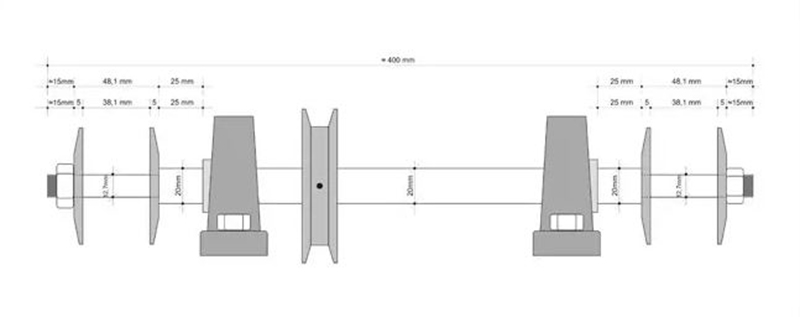

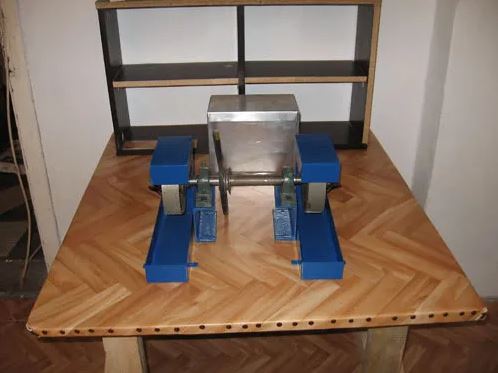

Since I had great problems getting one Lortone Beaver arbor (too high shipping costs, too long period of waiting etc.) I took Doc's advice: "Why not make your own? All it is is an arbor with a means to wet.". So I started making one. I am not over yet but it really seems that I am going to succeed. First blueprints.   I went with my plans to metal turner's workshop. I am pretty satisfied so far with results of his work, but he didn't managed to make adapter for polishing head. I also went with my blueprints to one workshop where my tin water pans were bended and welded. I bought some aluminium sheet for water shield for arbor bearings and belt but I cut it and bend it myself. I also realized that I don't have suitable and sturdy work bench where I could place my arbor and decided to make that to. Here are the results so far. Arbor  Bearings carriers  Splash guard/water pan  Work bench in progress  Work bench finished  Arbor set up not finished yet.  Close up  Splash guard for bearings and belt  Ed, please don't laugh too much to my carpentry skills. This is my first woodworking project ever. Thanks for looking. Zocky |

|

Zoran

freely admits to licking rocks

Member since September 2005

Posts: 880

|

Post by Zoran on Nov 17, 2006 20:44:32 GMT -5

By the way.

I am back.

|

|

|

|

Post by docone31 on Nov 17, 2006 21:12:58 GMT -5

Zoitka. Great work so far! I knew someone would do it.

Two points.

Make a polishing pad for the outside mounting nut for the side with the rubber drum. That would be a leather disc, mounted on a steel plate, with threads to tighten the rubber drum.

Vibration will be an issue. The wood table, which looks great, is not enough. Even though the drums run very smoothly, there is vibration, and torque. I would make a plate to bolt the I-beam members to. Then bolt to the table. Even the motor vibration will transmit to the drums.

Most machines that perform delicate operations have an heavy base. That alone dampens most vibrations.

You know, I gotta bite my tongue. You have designed a polishing head. If the machineist cannot really do it, you can cast it in aluminum. All you would need to do is design a furnace, and do green sand casting. If you have done this so far, you can definately do that.

Lindsay Publications has literature by David Gingery on makeing a furnace, lathe, mill, shaper, drill press. All you need for a furnace is an old hot water heater tank, some piping, propane, refractory cement.

You have designed what appears to be a very clean efficient lapidary grinder. I indeed approve. That unit will become your workhorse machine. I am looking forward to seeing your work. I bet we see some pretty good looking opals from that machine.

Great job.

|

|

blarneystone

spending too much on rocks

Rocks in my head

Rocks in my head

Member since March 2010

Posts: 307

|

Post by blarneystone on Nov 17, 2006 21:19:01 GMT -5

Holy Cow! Looks like you're doing a fine job there! Thanks for posting the pics. Now I'm thinking I should try to build one instead of buy one. I don't think I've ever seen a parquet work-bench before... outstanding!

Okay... now you should post some pics of your polished shapes. ;D It was your pics that really got me inspired to do some of my own....

Welcome Back Zotika~

Dan

|

|

|

|

Post by deb193 on Nov 17, 2006 23:15:57 GMT -5

If you still need the arbor adaptor for the end plate, You can get one already made. If the shipping is a problem, maybe I can send it. Graves company has them for $15  www.gravescompany.com/beltsand.htm www.gravescompany.com/beltsand.htm |

|

|

|

Post by joe on Nov 18, 2006 0:30:24 GMT -5

Very impressive Z! That looks like it's gonna work out real well for you.

|

|

|

|

Post by krazydiamond on Nov 18, 2006 16:11:24 GMT -5

ok, i'm impressed! welcome back, Zotika!

KD

|

|

jeffp

starting to shine!

Member since September 2006

Posts: 43

|

Post by jeffp on Nov 18, 2006 17:01:24 GMT -5

Looking very nice, it would be a good idea to put an 1/8 plate on your worktop to beef it up, as docone says.

Jeff P

|

|

stefan

Cave Dweller

Member since January 2005

Posts: 14,095

|

Post by stefan on Nov 18, 2006 17:39:32 GMT -5

Incredible- And soo much better than the Lortone Arbor!!! Nice work bench too!!! I have to aggree with doc that vibration is goning to be an issue- My lortone has a cast Aluminium base attached to the water tray- it makes the unit VERY HEAVY (close to 50 Lbs with the motor attached) I attached the whole tray to asheet of ply wood (reinforced by 2x4s) so my entire unit now excedes 60 Lbs- even with all that weight it will still shake the the entire work bench- (which initself weighs anoth 60 Lbs!) I would bolt that entire grinder to your workbench and maybe even bolt the bench to the floor- That should keep it stationary!

|

|

Zoran

freely admits to licking rocks

Member since September 2005

Posts: 880

|

Post by Zoran on Nov 18, 2006 19:54:26 GMT -5

Thank you guys.

As a matter of fact I was just wondering to use some heavy metal plate for base or to use only wooden plate. OK, you really convinced me. Those bearings carriers are actually very heavy. They are made of steel and weigh at least 6 lbs each. But I think that some more weight are going to be helpful.

Dan, I have to disappoint you. That is only linoleum (vinyl flooring) that L used to cover bench top plate made of hickory (it is not parquet).

Doc, I don't need to make polishing heads, I already have them. That guy just didn't succeed to make good arbor adapter. Just know I am considering to give up the idea to attach polishing head to grinder setup. I am thinking about making separate polishing machine with maybe two polishing heads. I do have spare washing machine motor and broken bench grinder for an arbor.

|

|

Zoran

freely admits to licking rocks

Member since September 2005

Posts: 880

|

Post by Zoran on Nov 18, 2006 20:10:51 GMT -5

Daniel, thank you very much for your offer, but I think that I am not going to need them for now. I'll maybe just change my metal turner. ;D

|

|

|

|

Post by stoner on Nov 18, 2006 20:41:38 GMT -5

Hey Zotika, excellent job. I think that arbor will give you many years of service, which is more than I can say for some of the commerical units being sold. For me, half the fun is making the equipment, especially when I can make it for a fraction of the cost.

Nothing to laugh about on your bench. It looks nice and sturdy and I was very impressed with the top matching your floor. If it were me, I'd put a shelf on the bottom for storing rocks or whatever. It will also add some strength to the bench. If you find that it begins to rock back and forth with use, you can correct that by adding plywood sides and fastening them to the framework. Keep us posted and welcome back.

Ed

|

|

|

|

Post by docone31 on Nov 19, 2006 19:29:52 GMT -5

Making you own polishing set up is the best idea. It keeps the really fragile surface of the polished stone away from contamination.

I have a polishing unit that is set up at 45*. That I really like. It is set up to use laps, 8". It polishes pretty well.

I got a thrown away table saw top to mount my bench grinder. It weighs about 75lbs. I mounted the unit on the table top, then mounted the table top on the bench. Worked real well.

You have done some real good work on that unit. You should feel proud.

|

|

snowdog

fully equipped rock polisher

RIP David Fildes, aka: snowdog

RIP David Fildes, aka: snowdog

Member since January 2005

Posts: 1,527

|

Post by snowdog on Nov 19, 2006 20:38:24 GMT -5

I can see it now ---" Zotika takes over rock polishing machine market in Europe! " ;D -- has now sold five million machines! looks like you are going to beat me being done with your machine way before me!!  --mine came to a stand still for awhile now ( not enough time for everything ) like the looks of everything you've done so far ! think it will work out good! |

|

|

|

Post by creativeminded on Nov 20, 2006 8:26:31 GMT -5

You did a great job on that grinder, good luck with it.

Tami

|

|

Zoran

freely admits to licking rocks

Member since September 2005

Posts: 880

|

Post by Zoran on Nov 23, 2006 19:02:16 GMT -5

As Stoner said, half the fun is making your own equipment (although, I miss the other part - making some cabochons). So I decided to make separate polisher also. After Doc agreed with the idea, I just couldn't do otherwise. I made my new polisher from some old used stuffs: broken bench grinder (dead motor), old washing machine motor, old pulley, old belt, aluminum plates leftovers from building grinder, pieces of wood and plastic box of candies. So it cost me virtually nothing. The main problem was how to reduce big rpm of driving motor (2900rpm). I found some old pulley which could reduce rpm at 1450, but arbor whole wasn't right. Then I remembered spare bushing that Daniel Lopacky kindly sent me with grinding wheels - and it fitted just right (thank you Daniel). And voila, this is how it looks building something (lapidary polisher) from nothing.   I also managed to finish shield from splashing water on arbor bearings and belt for my grinder.  I am, also, going to paint it in blue. With all this screws it looks to me like some kind of steam power machine. I like that old fashion look. I bought new motor for grinder and tomorrow I am going to metal turner to make me driving pulley. After that I'm going to be able to assemble and start my machine. I can hardly wait. |

|

|

|

Post by docone31 on Nov 23, 2006 19:11:51 GMT -5

You be makin some great stuff there. The only critique is to move the polish shield back a little to just 5mm away from the level of the polishing pad, and open up room for the diamond wheels.

You are doing some great work there. I really like the metal work.

I wish you were my neighbor. I am building an ultralight and I bet you could show me some things, especially with CAD. I can hold my own with an Heliarc.

Plate them all down, though. Even if you can get them balanced to -0-, there will still be ambient vibration from the armature. That alone will throw the diamond wheels out of balance by parasitic harmonics. It takes time, but eventually it will prematurely wear out.

If you can do all that , why not build a faceter? I posted plans somewhere on the forum. It is at least as good as my Ultracec.

That stuff looks real good.

|

|

Zoran

freely admits to licking rocks

Member since September 2005

Posts: 880

|

Post by Zoran on Nov 23, 2006 19:42:54 GMT -5

I wish you were my neighbor, to. It would be great pleasure for me to be of any help to big Doc. I would like all of you rth members to be my neighbors. In some way, you are. Here, in Serbia, there is not so many people that I can talk about things I am up to. But there is RTH forum with all those friendly people.

There are numerous very useful threads (many of them are yours, Doc). Some way you are my neighbors, my Internet neighbors. If this forum doesn't exist I would surely feel lonely in my lapidary activities. Thank you all so very much.

Doc, let's leave making faceter for future times. I plan to enjoy my grinder and polisher for some time, then try to use your tips concerning soldering and try to make some silver jewelery. I already bought one very useful book about metal-smithing.

|

|

|

|

Post by joe on Nov 23, 2006 19:54:03 GMT -5

Those are great lookin' machines Z!

Happy cabbing!

|

|

Zoran

freely admits to licking rocks

Member since September 2005

Posts: 880

|

Post by Zoran on Nov 23, 2006 20:03:16 GMT -5

By the way, Doc, I dont believe that you are actualy building airoplane. You are going to fly to the Moon, next. Am I right. you are planing to make a rocket, also?

|

|