AzRockGeek

has rocks in the head

Member since September 2016

Posts: 703

|

Post by AzRockGeek on Mar 30, 2020 19:15:51 GMT -5

Hi Jean, Just the expanded cover plate, a standard toggle switch will fit. I am sure MrRockpickerforever is familiar with these. Surprisingly, I could only find one on ebay, must be some UL/Safety issue thing.  h Is this the type of cover you are looking for, like the one on your pump?  |

|

|

|

Post by rockpickerforever on Mar 31, 2020 1:15:56 GMT -5

Hi Jean, Just the expanded cover plate, a standard toggle switch will fit. I am sure MrRockpickerforever is familiar with these. Surprisingly, I could only find one on ebay, must be some UL/Safety issue thing.  h Is this the type of cover you are looking for, like the one on your pump?  Ha ha, mrrockpickerforever can get it done it done alright and make it work, unfortunately, he doesn't always do it "pretty." I'll do some hunting for you online. |

|

|

|

Post by TheRock on Mar 31, 2020 1:18:44 GMT -5

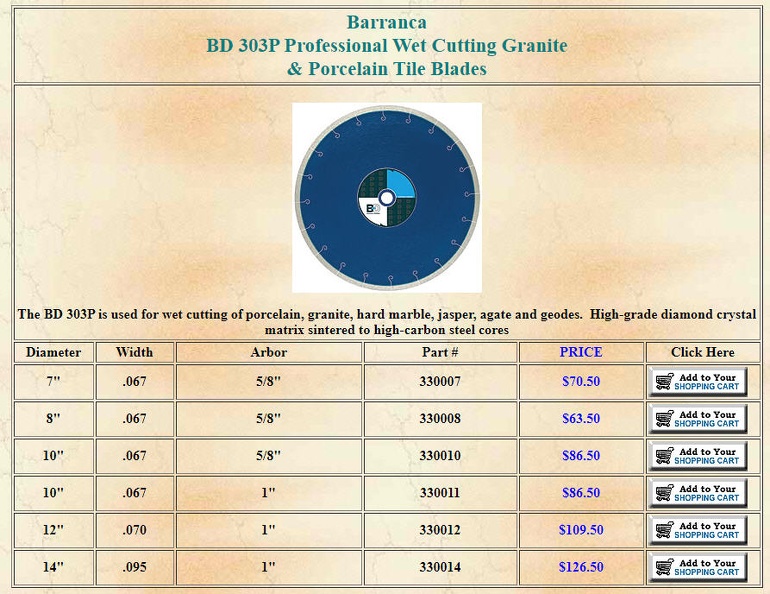

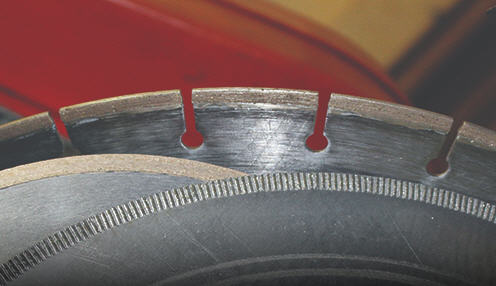

I cant see it either. aDave the Mfg of pretty much all the saws specify oil as the preferred Coolant. As The Article below states written by Bob Rush explains the different type of blades and states the Segmented blade are normally used on 18" and larger saws, Bob has been doing Lapidary since 1957. So I will go with what he says. I doubt a Segmented blade Would do any better on a small trim saw because your not removing that much material compared to a slab saw removing alot of material on BIG CUTS Besides BD only goes down to a 7" Lee says he has a 6" Saw.   By Bob Rush Frequently, on some social media sites as well as some forums, questions arise about the type of saw blades to buy for trimming or slabbing rock, and how to sharpen the blades. There are three basic types of saw blades, notched rim, sintered rim, and segmented rim. In the past, the notched rim blades were the most common blades one would encounter. They are made by notching the rim of the blade blank and embedding the diamonds into the notches. These blades perform quite well. Understanding Blade PerformanceAdvancements in blade manufacturing methods have resulted in a better performing blade. It is the continuous sintered rim blade. This type of blade is manufactured by mixing and bonding diamonds into a metal alloy and bonding that mixture together, under heat and pressure, to the outer rim of the blade core. This type of blade has superseded notched rim blades. he final type of blade to consider is the segmented blade. These blades have notches manufactured into the rim. The notches consist of a slot into the rim with a round hole at the bottom of the slot. The slots provide a path for the coolant/lubricant to reach the rim more effectively and remove rock waste from the rim area. The blades are primarily utilized in larger sizes, beginning with 18 inches and larger.

Addressing CoolantsThere also has been a lot of discussion about which coolants should be used on 10-inch trim saws. Many prefer to use water with additives because there is less mess during the cutting than when oil coolants are used. However, water isn’t a good coolant, because the flashpoint is quite low compared to the oils, which are commonly in use. At the point of contact with the rock, the heat builds up, and for an instant, the water flashes to steam, which doesn’t carry the heat away. Most blade manufacturers do not recommend using water because it causes premature blade wear. However, many people prefer the easy cleanup of water, and with it, they endure the need for more frequent blade replacements. Resharpening TechniquesWhen it comes time to resharpen a dull blade, there are numerous methods. As a blade is used, the diamonds in the rim abrade and break down, leaving small holes in the sintered areas of the cutting surface. The friction of the rock deforms this sintered alloy and moves the metal around, where it shields the existing diamonds, and the cutting action slows considerably. Suggestions for handling this have included cutting through obsidian, which is ineffective and cutting through an old silicon carbide grinding wheel, which is a better approach. John Rowland of Highland Park Lapidary, suggests turning a very coarse file sideways and strike the cutting edge of the blade vigorously around the diameter of the blade. This method is very effective in sharpening the blade. However, the above-mentioned method doesn’t sharpen the sides of the cutting surface. By gripping the sides of the blade, you can feel the wider cutting portion on the sides of the blade. If you can’t feel the wider area, the blade is worn out regardless of the remaining area of the diamonds around the rim. This step-up is required, so the blade cuts a slot, called the kerf, which is wider than the blade. This must occur so the rock, which is the focus of the cut, doesn’t rub on the sides of the blade during the process. If the rock rubs the blade, the blade gets hot, the rock gets hot, and they both expand, binding the blade in the rock. These cutting surfaces do at least as much rock removal as the outer edge of the blade, thus they wear just like the outer rim. My method to sharpen all the surfaces is to rub the outer rim vigorously sideways across the blade, with a piece of very coarse silicon carbide grinding wheel, followed by rubbing the sides of the blade vertically with the same grinding wheel piece. |

|

|

|

Post by roy on Mar 31, 2020 12:18:35 GMT -5

dang that little saw is cool as shit may have to trade you out of that one lol

|

|

|

|

Post by aDave on Mar 31, 2020 12:42:22 GMT -5

aDave the Mfg of pretty much all the saws specify oil as the preferred Coolant. As The Article below states written by Bob Rush explains the different type of blades and states the Segmented blade are normally used on 18" and larger saws, Bob has been doing Lapidary since 1957. So I will go with what he says. I doubt a Segmented blade Would do any better on a small trim saw because your not removing that much material compared to a slab saw removing alot of material on BIG CUTS Besides BD only goes down to a 7" Lee says he has a 6" Saw. I think there's a bit of confusion somewhere with the word, "agate" being applied to the blades you and I have mentioned. The blade in your post is used for cutting agates and other materials, and it's larger sizes would certainly dictate oil being used as a coolant. But, the blade I was referring to (and NRG as well) is actually named Agate Kutter. I just merely mentioned that the Agate Kutter (BD-305) was available in as small as a 5" size. The other blade being spoken about is the Hot Dog blade (MK-225), and it can be found as small as 4.5". Both of those blades are continuous rim and are not segmented and would be a good application for Lee's saw. I don't know where the oil vs water and segmented blade came into the discussion, as I was not advocating any one over the other.  |

|

|

|

Post by nowyo on Mar 31, 2020 13:16:15 GMT -5

That is a neat little saw there, Lee.

Russ

|

|

|

|

Post by TheRock on Mar 31, 2020 15:34:31 GMT -5

aDave the Mfg of pretty much all the saws specify oil as the preferred Coolant. As The Article below states written by Bob Rush explains the different type of blades and states the Segmented blade are normally used on 18" and larger saws, Bob has been doing Lapidary since 1957. So I will go with what he says. I doubt a Segmented blade Would do any better on a small trim saw because your not removing that much material compared to a slab saw removing alot of material on BIG CUTS Besides BD only goes down to a 7" Lee says he has a 6" Saw. I think there's a bit of confusion somewhere with the word, "agate" being applied to the blades you and I have mentioned. The blade in your post is used for cutting agates and other materials, and it's larger sizes would certainly dictate oil being used as a coolant. But, the blade I was referring to (and NRG as well) is actually named Agate Kutter. I just merely mentioned that the Agate Kutter (BD-305) was available in as small as a 5" size. The other blade being spoken about is the Hot Dog blade (MK-225), and it can be found as small as 4.5". Both of those blades are continuous rim and are not segmented and would be a good application for Lee's saw. I don't know where the oil vs water and segmented blade came into the discussion, as I was not advocating any one over the other.  On the Site it says the 301 blade is used for agates. Its basically an agate cutter, |

|

EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Mar 31, 2020 18:54:59 GMT -5

I think there's a bit of confusion somewhere with the word, "agate" being applied to the blades you and I have mentioned. The blade in your post is used for cutting agates and other materials, and it's larger sizes would certainly dictate oil being used as a coolant. But, the blade I was referring to (and NRG as well) is actually named Agate Kutter. I just merely mentioned that the Agate Kutter (BD-305) was available in as small as a 5" size. The other blade being spoken about is the Hot Dog blade (MK-225), and it can be found as small as 4.5". Both of those blades are continuous rim and are not segmented and would be a good application for Lee's saw. I don't know where the oil vs water and segmented blade came into the discussion, as I was not advocating any one over the other.  On the Site it says the 301 blade is used for agates. Its basically an agate cutter, I use a 301 to cut agates, but it doesn't say "Agate Kutter" on it |

|

|

|

Post by taylor on Mar 31, 2020 19:35:28 GMT -5

Barranca Diamond lists their BD-305 as 'Agate Kutter'--the name Agate Kutter being trade marked...

|

|

|

|

Post by aDave on Mar 31, 2020 20:20:38 GMT -5

On the Site it says the 301 blade is used for agates. Its basically an agate cutter, I use a 301 to cut agates, but it doesn't say "Agate Kutter" on it And I wouldn't expect it to. Sure, it, as well as a host of other blades are suitable for cutting agates. "Agate Kutter" is a name of a particular blade, much like "Hot Dog" is. taylor summed it up nicely... Barranca Diamond lists their BD-305 as 'Agate Kutter'--the name Agate Kutter being trade marked... So, when I and others have referred to "Agate Kutter," it's a specific blade with that name. That's not to say that there aren't other blades that can cut agate, because there clearly are. |

|

|

|

Post by taylor on Mar 31, 2020 20:28:13 GMT -5

In my very limited experience I have not seen a sliding table. Rockoonz please update us on its performance when you get it up and running! |

|

EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Mar 31, 2020 21:37:53 GMT -5

In my very limited experience I have not seen a sliding table. Rockoonz please update us on its performance when you get it up and running! Seems like it would work well. I believe greig uses one Saw with sliding table |

|

|

|

Post by taylor on Apr 1, 2020 0:26:41 GMT -5

Thank you for the link EricD . We had a tile saw for a short period of time...profound dislike. I already know that Rockoonz has good taste in saws. I'm interested in starting to do intarsia, so I'm curious about his results with this type saw.  |

|

|

|

Post by TheRock on Apr 2, 2020 8:14:10 GMT -5

I have its Big Brother FROM HF Been sitting for two years I Plan on Using with water and Additive on it it wont get used that often and will keep it blown out lubricated and dry.

|

|

|

|

Post by Rockoonz on Apr 2, 2020 12:40:25 GMT -5

I have volunteered to cut thunder eggs at the Rice Museum annual egg-stravaganza using a tile saw like that. It did the job, but I was soaked and, even wearing the hearing protection I use for shooting, my ears were ringing.

|

|

|

|

Post by Peruano on Apr 2, 2020 14:01:29 GMT -5

Stretching the topic a bit, I found an old photo of a somewhat unique slab saw in a book entitled Jewelry, Gem Cutting, and MetalCraft by W. T. Baxter. Its relevant to this thread in that the saw has a movable sled/vice but appears to lack a power feed. Instead of the usual gravity feed with cables and pullies, the saw has a rod-like handle that protrudes through the front of the cover which appears to have allowed the operator to gently push the rock through the saw without the proverbial bath of coolant. I've never seen such an innovation but its an improvement over not having any protection.  The saw is labeled Diamond Streamliner - W. C. Eyles, Hayward, CA. The publication dates for the pub was 1938 and 1942 for the 2nd edition. Just thought it was worth illustrating here. |

|

|

|

Post by Rockoonz on Apr 2, 2020 19:50:47 GMT -5

Peruano that is cool, I would love to see more info on that.

|

|

|

|

Post by Peruano on Apr 2, 2020 20:01:19 GMT -5

I'm not sure the saw is as simple as I presumed. I see what appears to be a chain drive along the side of the saw which may indeed be a drive mechanism. I also see a crank handle protruding from the front. Could one push the work through or crank it through by hand? It certainly looks like the front of the hood has a slot for that rodlike handle to protrude when the hood is down.

The same book had a great early model of a Covington saw with an hood that was open on one side. I'll post that photo in a different thread. I have a more modern Covington that has a stupid 3 sided hood for which oil splash is controlled with pizza pans and terry cloth towels. Go figure.

|

|

|

|

Post by parfive on Apr 2, 2020 20:03:43 GMT -5

I like The Pusher.  Don’t think it’s the perspective - the hood looks a little short to me. Maybe not all bad if you have to watch the blade easing into the cut. |

|

|

|

Post by Rockoonz on Apr 2, 2020 20:33:33 GMT -5

I'm thinking that chain drive runs 2 threaded rods that move the vice, rails and everything from side to side as a crossfeed for making slabs, probably a handle on the other side. The curiosity is killing me...

|

|