|

|

Post by talkingstones on Jan 5, 2014 16:19:14 GMT -5

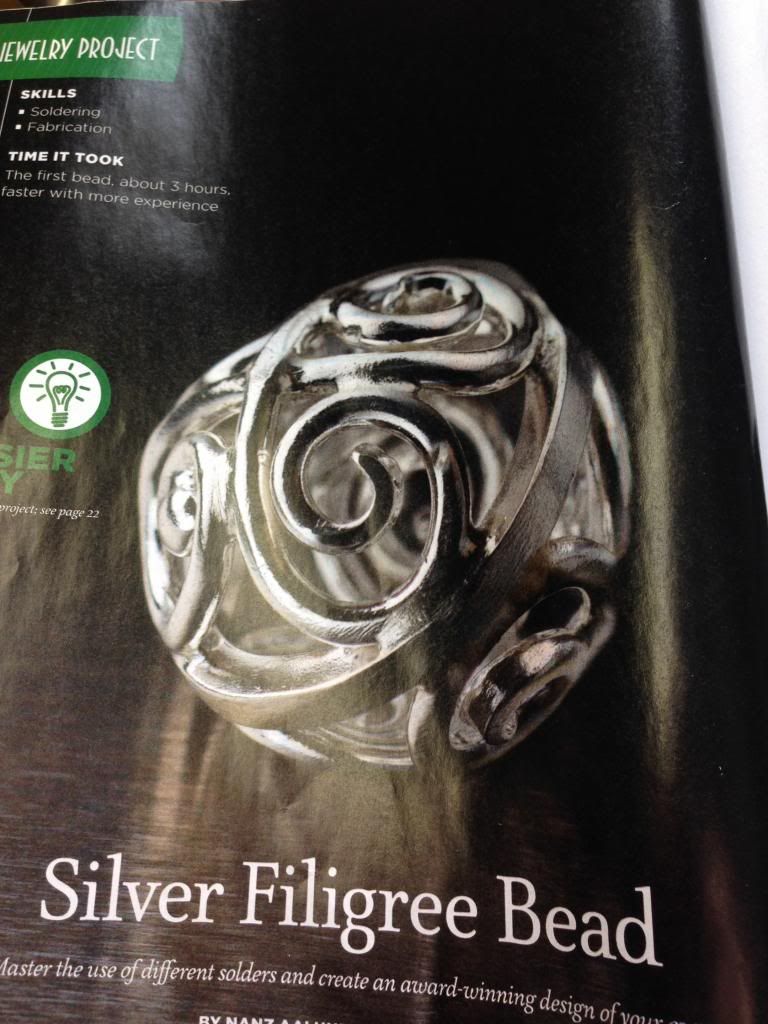

First projects are always hard but I think that this one is going to take the cake. I began this project over a week ago... On December 27th. I finished it today. While I would not recommend it as a starting project because I did get very discouraged at several points doing it, it was a very good project and I learned a ton about working with metal from it. This project is not my own design but was taken directly from the pages of Lapidary Journal and Jewelry Artist, December 2013 Issue, p. 20. The project is a filigree made by Jose Lins who is a student of Nanz Aalund.  While I would love to say it was a breeze and I had no problems working with it, I can't. As a first project it was a bear!!! I did, however get through it and have that first dreaded project behind me. Anyway, this is the journey...   [img src=" [img src="![]() i1198.photobucket.com/albums/aa450/talkingstones/Smithing/IMG_4711_zpsa7ccb5c2.jpg i1198.photobucket.com/albums/aa450/talkingstones/Smithing/IMG_4711_zpsa7ccb5c2.jpg" src="http://i1198.photobucket.com/albums/aa450/talkingstones/Smithing/IMG_4736_zps3cc60f01.jpg" style="max-width:100%;"]        The final piece that I was able to fabricate was made of bronze and sterling, soldered with generic solder that I cut from Home Depot. While not perfect, it is a good start and I learned enough from doing it that I can now move on. I am going to be taking a break for now on the smithing, though, as I have a portfolio and a trip out West to get ready for and that pretty much eats the rest of this month. February is coming, though, so this gives me time to contemplate my next project. Oh... The other thing I wanted to add is that this project was done from scrap wire that I had left over from wrapping. I think it's a good usage and the filigree will be a good usage for that!!!!  Anyway, thanks for looking! Cathy |

|

|

|

Post by gr on Jan 5, 2014 16:41:39 GMT -5

The bead turned out excellant for your first smithing exercise but, I love that bowl of experience  . That says alot! Take the break and come on out and we'll go hunt some rocks down around Holbrook  Should be good weather but if not, I'll let ya hound my front yard and shop  |

|

|

|

Post by rockjunquie on Jan 5, 2014 16:48:04 GMT -5

Wonderful!!!!!! You go, Girl!!! You picked a tough project, stuck to it, worked through your failures and frustration and ended up with a beautiful bead.  |

|

|

|

Post by talkingstones on Jan 5, 2014 19:59:16 GMT -5

Thanks, Tela and thanks Gary! The bowl is what I call "The bowl of carnage," lol!!! Hounding sounds good right about now so I'm putting you in charge of the weather! LOL! I could use some sun and warmer temps!!!

|

|

|

|

Post by gr on Jan 5, 2014 20:11:34 GMT -5

8-)I have a connection for that  |

|

|

|

Post by Pat on Jan 5, 2014 20:50:50 GMT -5

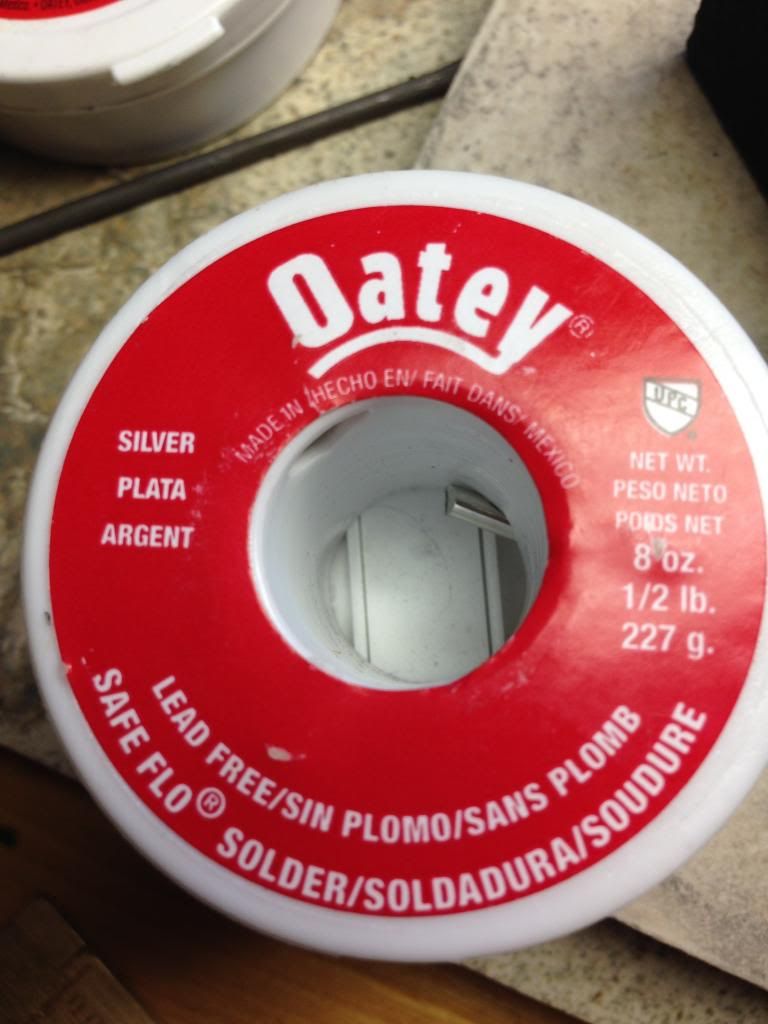

Wow! YOU DID IT! Congratulations. Great idea for using scrap. I'm wondering about the generic solder from Home Depot that you mentioned. Can you tell me more about it? New to me. Thanks.

|

|

Fossilman

Cave Dweller

Member since January 2009

Posts: 20,715

|

Post by Fossilman on Jan 5, 2014 21:22:21 GMT -5

Totally cool!

|

|

|

|

Post by talkingstones on Jan 6, 2014 6:02:02 GMT -5

Thanks Fossilman and Hi Pat! I used the flux and silver solder right out of Home Depot for this project. It's a soft solder but worked fine. With the bronze wire and on a first project it worked fine. Here's a photo of it. It comes as a thick round wire and when I figured out that I should hammer it flat and cut it into little pieces it worked much better than taking chunks off of it!!!  Hope that helps. |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,583

|

Post by jamesp on Jan 6, 2014 6:20:32 GMT -5

Looking at the bowl i see persistence. Looking at the bead the pay off. Really great result. That is exactly what it takes. Using cheap solder and learning w/it-great idea. I use this low temp silver solder. The wire is thin and it is so sting and silver. $10-$15 dollars with flux bottle w/easy applicator. It is 5% silver and 95% tin. I paint the flux on with a tiny painter's detailing paint brush so that the solder will only flow to the painted area. Just saying that this stuff is way user friendly and melts as low as any thing on the market(propane will easily work but i use a solder iron-too easy)  |

|

|

|

Post by talkingstones on Jan 6, 2014 6:41:32 GMT -5

Thanks James! Where do yo get it?

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,583

|

Post by jamesp on Jan 6, 2014 6:41:40 GMT -5

PS Soldering is a challenge to me. I am impressed. This is a ridge on the back of a Rhodesian Ridgeback dog. It is copper soldered to german silver. The excess solder bled out meaning i used too much. Due to the color difference it is visible and the damage is hard to remove. I should have used less solder. I take the thin solder and hammer it flat-3 pieces about 1/8 inch long and lay it on the silver. Then paint some flux. Then lay the copper on top. Then heat the whole unit up on a piece of metal while holding the copper image with a metal tooth pick until the solder melts and floats out under the copper. It takes practice....fortunately my customers like the 'aged effect' And pet jewelry(for pet owners)is a super hot jewelry market  Yes,this one is better  |

|

chassroc

Cave Dweller  Rocks are abundant when you have rocktumblinghobby pals

Rocks are abundant when you have rocktumblinghobby pals

Member since January 2005

Posts: 3,586

|

Post by chassroc on Jan 6, 2014 8:11:08 GMT -5

What a great first project!

Stunning work...soldering is challenge for most, if not all of us.

The difficulty lies in the repetition(or lack of it).

That piece has trouble written all over it...but that's probably a better way to become skilled

(and I dont think it took all that long for a first project with some restarts to it)

Charlie

|

|

|

|

Post by talkingstones on Jan 6, 2014 8:23:39 GMT -5

I think the biggest problem I had with this was solder breaking but even more than that was the metal would actually "jump" once it got to a certain temp and color. Also, after heating the metal it would become brittle and just break the solder if I tried to do anything with it. Another difficult aspect of it was that it was a multi-step piece with a lot of reheating and with every reheating, the metal became more brittle. I kept losing the joint on the domes because of that and it was really aggravating. Wiring them for the final joinings worked well though. It just took me forever to get to the point where I could do that! LOL!

|

|

|

|

Post by Donnie's Rocky Treasures on Jan 6, 2014 8:33:35 GMT -5

I'm with Charlie on this one! It looks like a difficult project but those are the ones you learn the most on. Well, at least that's the way it works for me. I think you did a great job on it!

|

|

|

|

Post by 1dave on Jan 6, 2014 10:13:28 GMT -5

I think the biggest problem I had with this was solder breaking but even more than that was the metal would actually "jump" once it got to a certain temp and color. Also, after heating the metal it would become brittle and just break the solder if I tried to do anything with it. Another difficult aspect of it was that it was a multi-step piece with a lot of reheating and with every reheating, the metal became more brittle. I kept losing the joint on the domes because of that and it was really aggravating. Wiring them for the final joinings worked well though. It just took me forever to get to the point where I could do that! LOL! I like to sit in the car on a cold morning and watch the frost crystals melt. When they hit that particular temperature they will jump as much as a half inch away and become a drop of water! On soldering, if you melt your solder and drop it on cold metal, it will just bounce away. Stick the solder to the metal with flux, and as the metal heats up it will start moving around, then puff into a sphere, then flatten out and flow over the surface following the flux and heat. Get to know your enemy and it can become your friend. |

|

|

|

Post by rockjunquie on Jan 6, 2014 10:37:07 GMT -5

Cathy, I don't want to offend or anything, but you are using the wrong solder. Most of your difficulties stem from that. The silver solder you are using is different from the silver solder jewelers use. When you use the right solder, what happens is that the heated metal molecules will start to spread apart. Then, at the right temp, the solder will run in and fill the spaces. That is why a join is so tough and why you only need to fill the join not the space around it. Pick up some different hardness rated silver solder for your next project. It will be much easier. You start with the hardest silver and work your way down to extra easy. Also, although I hate using flux, it can be your friend. At the point that the flux goes clear, easy solder is almost ready to flow. That's really useful to know and visualize. I like to pick solder, so it's really helpful to me. Anyway, I don't mean to sound like a know it all. I have just learned this myself. My initial try, a few years ago, at learning to solder was a dismal failure. I just hated to use the flux. This time, I am going slow and trying to nail down the basics.

|

|

|

|

Post by Pat on Jan 6, 2014 11:18:47 GMT -5

jamesp if you sweat solder the ridgeback first, you might get the result easier. To sweat solder: put the solder onto the smaller piece. Heat it until it melts, but does NOT flow. Turn the piece over. Reheat till the solder flows. Sometimes you can actually see the the top piece sigh and relax onto the bottom. Sometimes you can see the solder as a very thin line around the edges. talkingstones: I'm going to try this when I get enough scrap of the right size. Thanks for showing and discussing.

|

|

|

|

Post by 1dave on Jan 6, 2014 11:44:07 GMT -5

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,583

|

Post by jamesp on Jan 6, 2014 12:05:53 GMT -5

Well that just makes a lot of sense. Never thought about small to big. Putting the solder on the small piece first. Then sticking it to the large piece.

I have thrown those away because of excess solder pooled. And i understand what you are saying about the top piece 'sigh' ing in to the bottom piece. That part is exciting:)

Thanks a lot Pat-big help for old problem.

|

|

|

|

Post by pghram on Jan 6, 2014 19:55:17 GMT -5

That is a beautiful bead.

Rich

|

|