ontariojoe

off to a rocking start

Member since October 2014

Posts: 24

|

Post by ontariojoe on Oct 30, 2014 14:29:31 GMT -5

I've been browsing the forum and checking out all the home made machines which all look great! Being cheap, I refuse to spend money on something many people have built themselves and I can do too. I bought this 1/4 hp 1725rpm electric motor from our city dump for $2. it runs great and is reversible. I believe it was used as a furnace fan blower motor. It had a small belt pulley which i removed. The shaft is 1/2" and is D shaped. I've been looking for an extension for the motor locally but can't seem to find one. I'll have to order online. Can anyone suggest a supplier?  This is the adapter I need. I believe its called an arbor?  |

|

spiritstone

Cave Dweller

Member since August 2014

Posts: 2,061

|

Post by spiritstone on Oct 30, 2014 19:14:47 GMT -5

![]() been browsing the forum and checking out all the home made machines which all look great! being cheap i refuse to spend money on something many people have built themselves and i can do too. i bought this 1/4 hp 1750rpm electric motor from our city dump for $2. it runs great and is reversible. i believe it was used as a furnace fan blower motor. it had a small belt pulley which i removed. the shaft is 1/2" and is D shaped. I've been looking for an extention for the motor locally but can't seem to find one. i'll have to order online. can anyone suggest a supplier?

This is the adapter i need. i believe its called an arbor?  Do you have a Princess Auto store? Check out there site. You wont have to ship across the border. |

|

ontariojoe

off to a rocking start

Member since October 2014

Posts: 24

|

Post by ontariojoe on Oct 30, 2014 20:12:57 GMT -5

yes i do. i was very surprised they didnt carry the part. had a good selection of pulleys but no arbors. perhaps there online site.

i managed to find one at a local Canadian Tire. i'll be buying some more parts tomorrow and update as i go.

|

|

jerrys

spending too much on rocks

Member since February 2014

Posts: 263

|

Post by jerrys on Oct 31, 2014 13:25:49 GMT -5

With the adapter, are you going to have direct drive and 1750 RPM lap? Whats the diameter of the lap? What speed will the lap operate at?

|

|

ontariojoe

off to a rocking start

Member since October 2014

Posts: 24

|

Post by ontariojoe on Oct 31, 2014 22:08:45 GMT -5

Yes. i am running direct drive. 1725 rpm yes. i made up a 8" backing plate out of wood.

i made a mistake. the electric motor im using is 1725rpm

|

|

ontariojoe

off to a rocking start

Member since October 2014

Posts: 24

|

Post by ontariojoe on Oct 31, 2014 22:19:01 GMT -5

I bought more parts today and put it all together. Still have a water drip system to make up and a drain to collect the water. Here is the arbor I'm using with my motor. It's for a 1/2" shaft.  Arbor mounted on the motor.  A plastic dish bought from the dollar store. It was used for doing dishes. I cut a hole in the bottom for the arbor to fit trough.  I used the top off a spray paint can I had laying around. Used my Dremel to cutout a hole for the arbor to go through and also shortened the height of the cap so it would not rub against the wooden backing plate. The cap is hot glued down to the plastic dish. The plastic dish is screwed and hot glued to the wooden platform everything is built onto. The hot glue should act as a sealant. If it leaks I'll use some silicone.  |

|

ontariojoe

off to a rocking start

Member since October 2014

Posts: 24

|

Post by ontariojoe on Oct 31, 2014 22:32:01 GMT -5

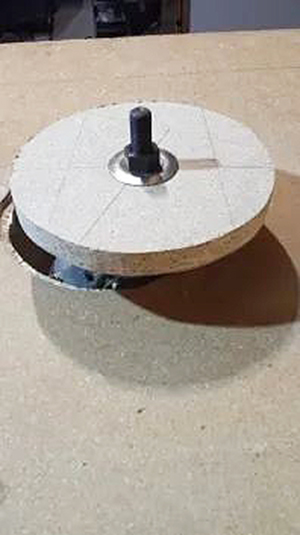

This is the 8" wooden backing plate I made. No vibration.  I used this 3m spray adhesive to stick a disc of waterproof silicone carbide paper I bought.  And it's mostly complete just the water left to do.  I wanted to try and grind a plain rock I had. I used a spray bottle to spray some water on the wheel as I worked.  As you probably guessed, the silicone carbide paper I used doesn't work.  It did make a small mark to the stone but I'll need to buy diamond discs.  |

|

ontariojoe

off to a rocking start

Member since October 2014

Posts: 24

|

Post by ontariojoe on Oct 31, 2014 22:43:44 GMT -5

Any thoughts or suggestions?

here is a price break down of the parts i have in this machine.

$2 used 1/4 hp motor

$9 arbor to attach grinding disc

$1.50 plastic bowl

$0 spray paint cap. had laying around

$0 wood used to make 8" backing plate. had laying around

$5 silicone carbide paper. but doesn't work.

$12.50 without the paper.

i have a GFIC and switch to wire up still. safety first!

|

|

|

|

Post by captbob on Oct 31, 2014 22:57:04 GMT -5

I just did a quick Google search for wet sanding discs (like for sanding on a car) and found all kinds of options using silicone carbide. Was the disc you used there for wet use? What size disc are you needing? ETA: Just reread and saw you used "waterproof silicone carbide paper". hmmmm.... What is all the green stuff on the used disc? www.abrasives4sale.com/h&L-disc-sc.htmlSays: 4" and 5" W/D Silicon Carbide sanding discs with hook & loop back. Can be used wet or dry. These discs have a 1/2" center hole for use with wet sanding stone tools. Hook & loop discs will significantly outlast PSA discs. Used mostly on granite, marble, stone, and other ceramic materials. |

|

ontariojoe

off to a rocking start

Member since October 2014

Posts: 24

|

Post by ontariojoe on Oct 31, 2014 23:15:58 GMT -5

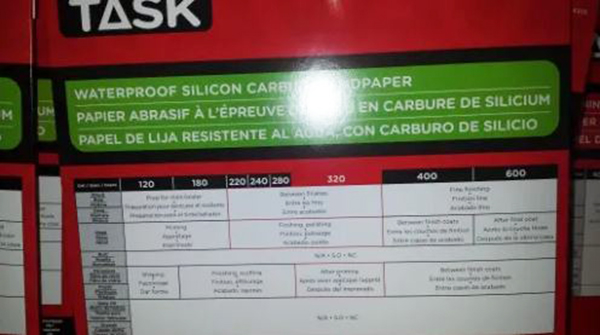

waterproof silicon carbide sandpaper. the grit was 320 i'm sure this is not the right stuff to use. oh well, live and learn. the green stuff is the actual paper, the grit has just worn off. i wanted 8" disc's but might drop down to 6" to start with. i checked the link you provided. those are nice and a good price but i worry about getting hit at the border with duty fees. (i'm in Canada) I have been browsing Amazon.ca and found some 6" discs www.amazon.ca/Quality-Electroplated-Diamond-coated-wheel/dp/B00BB39DXK/ref=sr_1_209?s=hi&ie=UTF8&qid=1414814755&sr=1-209they also have 8" ones but not as many grits to choose from. would these 6" discs work? |

|

|

|

Post by captbob on Oct 31, 2014 23:25:20 GMT -5

What is the brand and exact name of what you were using?

Canada charges you fees to buy something online? How much in fees? Can't someone you know in the States buy them and ship to you to get around the fees?

ETA: You really need someone that uses a machine like this to answer the "what to use questions". Sorry I don't understand why "wet" discs won't work.

|

|

ontariojoe

off to a rocking start

Member since October 2014

Posts: 24

|

Post by ontariojoe on Oct 31, 2014 23:33:04 GMT -5

Here is a picture of the sandpaper I tried.  It's made by TASK. It comes in an envelope with about 4 or 5 11 x 7" sheets. No. I don't know anyone from the States. Yes, I usually get hit at the border when getting stuff shipped. They call it brokerage fee's. This is an additional fee on top of the shipping fee I already pay when I order something online. Not always, but usually. |

|

ontariojoe

off to a rocking start

Member since October 2014

Posts: 24

|

Post by ontariojoe on Oct 31, 2014 23:35:57 GMT -5

Alright, thanks captbob. i'll make a new thread asking what types of grinding discs people are using on these flat laps.

|

|

quartz

Cave Dweller  breakin' rocks in the hot sun

breakin' rocks in the hot sun

Member since February 2010

Posts: 3,360

|

Post by quartz on Nov 1, 2014 23:30:15 GMT -5

I have tried both paper and cloth backed discs on our 6" lap, cloth works well, paper very poorly.

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,663

|

Post by jamesp on Nov 2, 2014 5:54:31 GMT -5

Yep, cloth backing. Adhesive backing great for securing. Check out this company, at least for info. I had custom 18 inch SiC adhesive backed cloth discs cut rather cheaply from a company similar to this many years ago. sandpaperamerica.com/products-page/sheets/ |

|

ontariojoe

off to a rocking start

Member since October 2014

Posts: 24

|

Post by ontariojoe on Nov 11, 2014 21:01:29 GMT -5

A little update. Finished a gravity fed water system and drain. Seems to work well but I have the odd leak. Will take care of those soon enough. I had ordered 6" diamond disks off Amazon. They were actually selling for a company called Kent Blades out of Quebec. These are the first lapidary disks I've ever owned so I can't compare to others but they look good and work well. I ordered 1 80 grit and a 240 grit. Will be ordering finer grits shortly. Heres a few pics.   My first rock I grinded to test.  |

|

|

|

Post by rockhoundgingerman on Sept 7, 2015 14:12:46 GMT -5

Is is thread still open ? Last post I saw was last year. Could use a little help:) trying to make my own flat lap aswell!

|

|

|

|

Post by jakesrocks on Sept 7, 2015 15:30:24 GMT -5

I believe 1725 RPM is going to be too fast for a flat lap. You may have to use a pulley system to at least cut your speed in half.

320 grit is much too fine to start out with. Get a variety of discs, starting with around 80 grit & work up to your finer grits.

Find a way to positively isolate that motor from your water feed. A little water down the open end of your motor may light you up like a Christmas tree.

|

|

NDK

Cave Dweller

Member since January 2009

Posts: 9,440

|

Post by NDK on Sept 8, 2015 20:14:45 GMT -5

I run my home made lap at 1725. It's set up similarly to Joe's & it works great.

|

|

ontariojoe

off to a rocking start

Member since October 2014

Posts: 24

|

Post by ontariojoe on Sept 24, 2015 14:46:28 GMT -5

Hello everyone.

Sorry, been busy with life and haven't been around.

My flat lap is still running well. I do have it taken apart at the moment for some improvements. Nothing major.

|

|