jamesp

Cave Dweller

Member since October 2012

Posts: 36,663

|

Post by jamesp on Mar 11, 2018 4:48:02 GMT -5

This lap will also have the odd duty of grinding color areas off of expensive fuse friendly glass using a steady water flow and capturing shavings in a bucket. Need the color agents for fusing glass. Lots of water so the heavy armor. Will add safety guards and rain protection as it will be outside most of the time. 14 inch bowl, 14 inch cover, 1/4 HP, 800 RPM. Had to butcher the motor mount plate bracing to get motor shaft parallel to drive shaft. So the obvious ugly repairs. Focused on lots of bracing for smooth rotation. Thanks for all the advise and a special thanks to Chuck. I have made a living using home made machines to produce products for myself and companies employing me. This type work has always been my top interest in life. ETA Need to add drip tank and water feed attachment for garden hose. Waiting to find best spot for water input.    drive shaft bracing  Motor mount bracing where major surgery took place. Not pretty but alignment accomplished. Lower left motor bolt had to be removed to screw plumbing elbow on to pipe. Bit tight in there.  |

|

|

|

Post by Drummond Island Rocks on Mar 11, 2018 5:21:21 GMT -5

Looks ready. Did it get a test run yet to see how balanced it is? Water drip as close to center as possible. Water will naturally flow from center out. My first thought when I seen it complete was the old Weber charcoal grills. They still make covers for those and one might work for your lap.  Chuck |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,663

|

Post by jamesp on Mar 12, 2018 2:53:58 GMT -5

Looks ready. Did it get a test run yet to see how balanced it is? Water drip as close to center as possible. Water will naturally flow from center out. My first thought when I seen it complete was the old Weber charcoal grills. They still make covers for those and one might work for your lap.  Chuck Ha great analogy, maybe Weber should start making laps. My fire pit tooling was a big help laying out and centering this project. It runs smooth. Never know about rotational machinery. Biggest balance concern was the heavy cast iron 6 inch sheave that the backing plate sits on. I static tested it and it seemed balanced from that minimal test. It is the first time I have ever used a diamond wheel with so much flat grinding surface. That alone was a treat. The softer glass plugs up the 60 grit wheel in a hurry so a higher water flow rate will definitely be needed. May have to be more of a spray than a drip. May have to weld a strategically placed fitting to spray water at center and main grinding zone. I may add a 90 degree-to-wheel slide in fence that will allow squaring and polishing up to 3.5" inch thick square glass bricks. Being steel peripherals can be welded easily to it. Once dialed in and bugs worked out I may make a stainless 12 inch unit as I can get the bowls in stainless. This one slapped together with junk steel. At 800 RPM the 1/4HP motor puts out a lot of torque and I could not slow it down at all with high grinding pressure. Certain that the added friction of a glass brick will slow it down. Very content, again thanks for all the help. |

|

|

|

Post by Garage Rocker on Mar 12, 2018 3:02:05 GMT -5

Looks solid. I'm sure it will see many miles of use. Nothing like doing it yourself!

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,663

|

Post by jamesp on Mar 12, 2018 7:56:18 GMT -5

Looks solid. I'm sure it will see many miles of use. Nothing like doing it yourself! Let's try something other than a king kong and a tile saw Randy. Still like the tile saw for making tumbles using that tuck blade. Time to move on to more finessed product - hate sitting and grinding for more than minutes. |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,663

|

Post by jamesp on Mar 21, 2018 12:54:12 GMT -5

This lapper will probably be left outside and used outside for messy glass grinding production work. It is a heavy 8 inch lap. A roof was welded over the motor. A 3/4 NPT fitting to allow attaching a garden hose w/control valve. A guard. A pull around handle. Inside of bowl has a 1/4" NPT or 1/8" NPT capability via bushing. Water feed to be tuned. A drip box w/valve will probably be threaded directly to the heavy 3/4" NPT hose fitting when not using garden hose. May mount a drip container on the top cover as it sits firm. Motor rain guard to left, pulley guard to right, 3/4" to 1/4" NPT bushing welded in at top. Rotation clockwise  Further splash protection for higher water flows as glass plugs up the wheels quickly.  |

|

|

|

Post by rockpickerforever on Mar 21, 2018 13:10:56 GMT -5

This lapper will probably be left outside and used outside for messy glass grinding production work. It is a heavy 8 inch lap. Motor rain guard to left, pulley guard to right, 3/4" to 1/4" NPT bushing welded in at top. Rotation clockwise  James, if you are saying the lap turns clockwise, then your drip is coming in from the wrong side. On the Ameritool flat lap I have, the water comes in exactly as you have, but it turns in a counterclockwise direction!

Just saying'

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,663

|

Post by jamesp on Mar 21, 2018 13:46:07 GMT -5

This lapper will probably be left outside and used outside for messy glass grinding production work. It is a heavy 8 inch lap. Motor rain guard to left, pulley guard to right, 3/4" to 1/4" NPT bushing welded in at top. Rotation clockwise  James, if you are saying the lap turns clockwise, then your drip is coming in from the wrong side. On the Ameritool flat lap I have, the water comes in exactly as you have, but it turns in a counterclockwise direction!

Just saying'

I have yet to water feed yet Jean. I may add another similar feed on the other side depending on flow conditions. I do like the weldable steel construction making any type of add on so easy. Probably going to add a shelf system for easily accessing 6 different abrasive discs handily. And any other tools that need to be used when lap grinding. A complete tote around rig. You have a job to do here and might as well have everything at finger tip reach regardless of size and bulk. High priority - on/off switch and water resistant at that for changing discs |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,663

|

Post by jamesp on Mar 22, 2018 10:09:35 GMT -5

I made the drip container rockpickerforever to be movable to the entire center area of the abrasive disc. Note valve that has a removable drop in stem that is older than you and I. They don't make them like that no mo. Note old school bung top 2 gallon container, also old school bulletproof. rated for jet cargo. Make #1 abrasive storage containers, epoxy coated innards.    |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,663

|

Post by jamesp on Mar 25, 2018 9:58:52 GMT -5

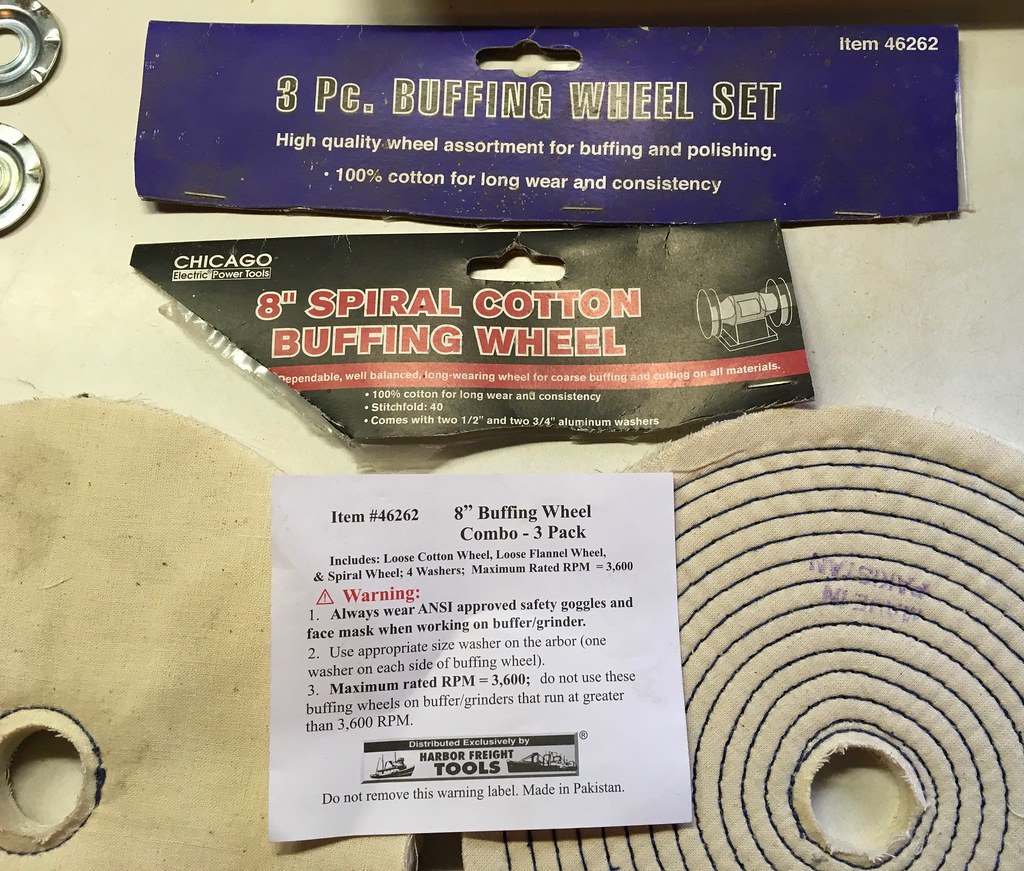

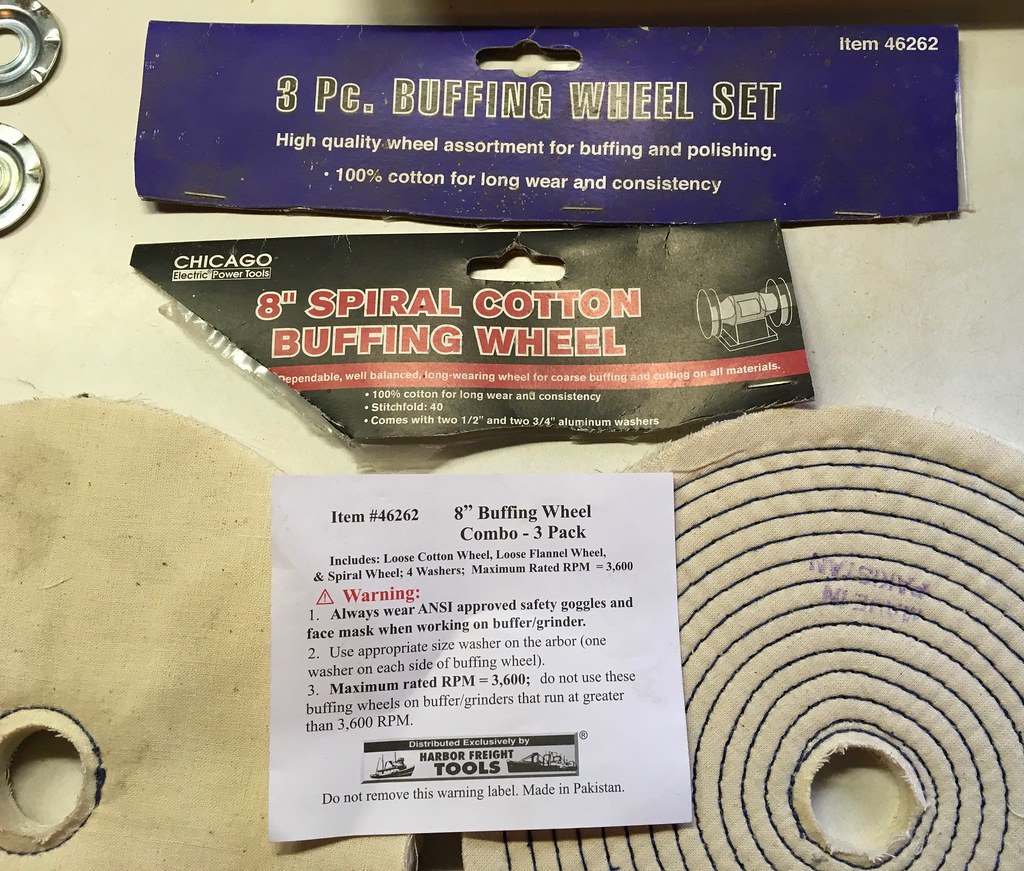

Drummond Island RocksCheck out these pads. They are 8 inch grinder pads. Some different stitching methods. Cheap, Harbor Freight. Going to give them a try on the 8 inch lapper. The hole fits the my particular clamping collar for accurate centering. ~1 inch hole ?? Spins very true and balanced. Being laid down on a grinding plate and they stay put very well. The edge is actually the intended contact point, I don't see a problem with charging the side with diamond paste/aluminum oxide. Might prefer the more common full stitched

|

|

NRG

fully equipped rock polisher

Member since February 2018

Posts: 1,688

|

Post by NRG on Mar 25, 2018 12:03:09 GMT -5

You will be 92 years old building these for hobbyists like that Al Sedona dude does for intarsia folks. Quietly making a few hundred dollars a day and enjoying a fun and relaxing retirement. Congratulations!

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,663

|

Post by jamesp on Mar 26, 2018 8:03:12 GMT -5

You will be 92 years old building these for hobbyists like that Al Sedona dude does for intarsia folks. Quietly making a few hundred dollars a day and enjoying a fun and relaxing retirement. Congratulations! Clean it up and set it up on a welding jig that aligns all that rotating crap and you would have a sweet product. This one is just a one-off. A bit treacherous to get alignment dialed in. Wife got on it first and spent a half a day. First time she ever did any lapidary type grinding. Not that big of a market for flat laps is there ? |

|

NRG

fully equipped rock polisher

Member since February 2018

Posts: 1,688

|

Post by NRG on Mar 26, 2018 9:14:47 GMT -5

Not that big of a market for flat laps is there ? I'm constantly amazed by the volume. This is something I have studied for my entire time in lapidary. It's bigger than reptiles and reptiles was huge. Aside from demand, price plays a role. I'll bet you could find a sweet spot that balances your time and profits with demand. Home Depot ain't forever and I have my eye on a few products myself. You will easily solve that motor mount alignment. Once placement is set, an alignment jig is put into play. Then you are off to the races. |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,663

|

Post by jamesp on Mar 26, 2018 13:17:30 GMT -5

Not that big of a market for flat laps is there ? I'm constantly amazed by the volume. This is something I have studied for my entire time in lapidary. It's bigger than reptiles and reptiles was huge. Aside from demand, price plays a role. I'll bet you could find a sweet spot that balances your time and profits with demand. Home Depot ain't forever and I have my eye on a few products myself. You will easily solve that motor mount alignment. Once placement is set, an alignment jig is put into play. Then you are off to the races. This one has a few too many components and welds for much interest in mass producing Scott. And I am not sure about insuring such a product with a nip point. Not to fond of selling rotational or electrical equipment either. Product liability insurance would be a concern. |

|

NRG

fully equipped rock polisher

Member since February 2018

Posts: 1,688

|

Post by NRG on Mar 27, 2018 10:32:36 GMT -5

Yeah, I get the product liability perspective

|

|