one80mike

freely admits to licking rocks

@(-_-)@ Princess Leia!

@(-_-)@ Princess Leia!

Member since February 2007

Posts: 908

|

Post by one80mike on Mar 12, 2007 20:40:01 GMT -5

Hey rockscateers,

I have read about a lot of you using a workforce tile saw to cut shapes, agates and small slabs and I wanting to start doing the same stuff. Unfortunately your workforce tile saws are unique to Home Deopt and Home Depot has not sprung up in the wonderful land of Oz. I did, however, see something that looked very similar yesterday. (similar to the saw, not the store)

So, what I am wanting to find out is what sort of things do I need to be looking for in a smalll tile saw so that I can start doing some cutting.

What sort of features would it need?

What sort and size of blade?

Do I need to be concerned rpm or power?

Are there any sorts of pitfalls I should be aware of?

Reading LWR's thread about standing behind the saw and everyone's responses has been helpful so thanks for that but some help with what I should be looking for would be great.

Thanks in advance folks,

Mike

|

|

|

|

Post by Jack ( Yorkshire) on Mar 14, 2007 4:24:59 GMT -5

Hi Mike,

have a look at the tile saws around in the decorators super stores or whatever You can ditch the blade and get a proper one from Rockshed USA (or one from across the sea from you !!!!) Richo are also good.

Consider the future are you in rocks for a long time or the short haul ?

Is it a business ? or just a hobby?

The answers you have will guide you as to weather you purchase a big expensive machine with guides vices and stability or the super market modle.

I have a small 6" saw and grinder" Rockraskel " I was given 10 year ago which does the job for me.

The supermarket modles spray water around a bit , but you could fit a drip feed that would cut your "free" showers down any way where you are I suppose its quite hot and enjoyable to use such a saw

I get covered in oil its all part of the joys of sawing rocks !!

Good luck with your purchase.

Jack

Yorkshire UK

|

|

stefan

Cave Dweller

Member since January 2005

Posts: 14,113

|

Post by stefan on Mar 14, 2007 10:51:32 GMT -5

OK I will try to help based on my 3 Plus years using the Workforce.

First- problem areas:

THe workforce uses a 7 inch blde- (and a kinda thick one at that) 7 inch is not a Lapidary standard- so getting thin blades is difficult (and expensive--- the saw costs $88 and a good 7 inch thin blade lapidary blade can go up from $50 to $100's- if you can even find one)

-there is no feed on this saw- everything is hand fed- not a problem if your careful

-messy messsy messy- this saw sprays- there are shields and such- but stuff is gonna get wet!

-Size- Ideally the mx size of a cut is about 1/3 blade diameter- so that means the ideal cut size for the work force is a little less than 2 inches- there are way around this but even so the MAX cut on the Workforce is only 4 to 5 inches)

Now for the good parts!

-Price- $88 brand new- with a pretty good blade- There are cheaper saws out there but the workforce stands out for the next reason

-construction- the Workforce uses very little plastic- the saw body and tabletop are STEEL! the only plastic used is in the motor housin, and watertray- Other saws have a lot more plastic- and that is not good for continued use

-ease of use- the WF is a plug and go saw- I plug it in, fill the watertray- and start cutting! It requires very little setup- and cleanup is easy too- less than an hour to clean it up (I strip it down every time!)

-watercooled- No oil to buy, filter, or get everywhere- just some dirty water to dump in the garden when I'm done.

-Cheap Blades- Yes they are thicker- but for less expensive material you just can't beat a $26 Blade and the thicker blades are less prone to warping and dishing

- Hand fed is sometimes a good thing- especially when I cut shapes or trim slabs

So I guess the important things to look for in a cheaper saw (lets call it a trim saw) is heavyduty construction

price

blade availability

ease of use and cleanup

Nobody can tell you how much you will use a saw- I know personally I use mine a lot more than I ever thought I would- From everything to cutting small slabs- to cutting crosses, to triming slabs, to make preshaped tumbling rough- it is just too much fun!

|

|

one80mike

freely admits to licking rocks

@(-_-)@ Princess Leia!

@(-_-)@ Princess Leia!

Member since February 2007

Posts: 908

|

Post by one80mike on Mar 14, 2007 19:32:51 GMT -5

Thanks Jack and Stefan, that's the sort of stuff I am looking for.

As far as blades go, I'm understanding that thinner is more desirable but often more expensive if the saw uses an uncommon sized blade. Do the blades have "teeth" or are the fully round and really just on the cutting power of the diamonds?

If anyone could post a picture of their saw and specifically what the blade looks like, that would be sweet.

Mike

|

|

|

|

Post by sandsman1 on Mar 15, 2007 0:39:12 GMT -5

|

|

stefan

Cave Dweller

Member since January 2005

Posts: 14,113

|

Post by stefan on Mar 15, 2007 13:46:25 GMT -5

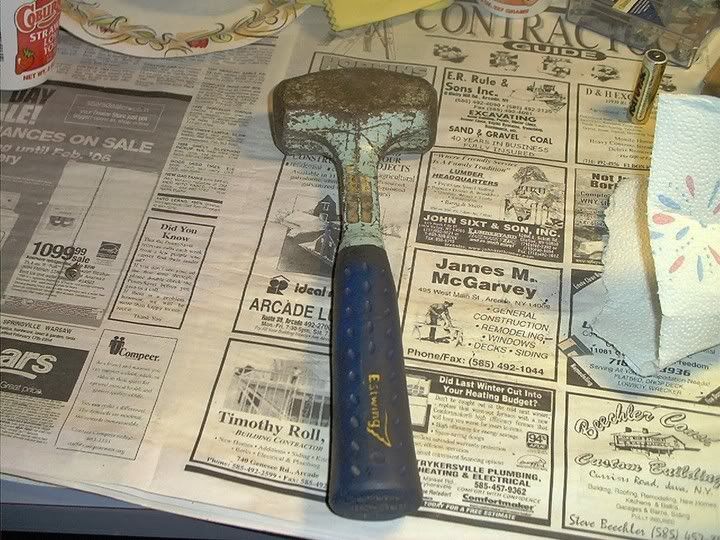

close up of a standard Diamond Blade (this one was dinged by a WAY TOO BIG ROCK- but the saw blades are essentially smooth- with just the rim of diamond doing the work  Saw with homemade shields  Without sheilds- THis was a rip fence that came with the saw- I only used it 2 or 3 times- But I did not like it- so I freehand everything   Saw alternatives (LMAO) |

|

|

|

Post by Jack ( Yorkshire) on Mar 16, 2007 3:26:52 GMT -5

Hi Mike . Thinner blades are good for cutting(Trimming) expensive rock Oplal ect. But do buckle if you are not carefull , I use the BD301 for gereral cutting. This is where I get mine from and here is a good picture of them !! therockshed.com/diamondblades.htmlHave a good day Jack Yorkshire UK |

|

one80mike

freely admits to licking rocks

@(-_-)@ Princess Leia!

@(-_-)@ Princess Leia!

Member since February 2007

Posts: 908

|

Post by one80mike on Mar 19, 2007 6:46:43 GMT -5

Again guys,

thanks so much ofr taking the time to respond and take photos and upload them. I really appreciate it.

My birthday's coming...so a tile saw may be too.

|

|