adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,774

|

Post by adrian65 on Apr 17, 2007 13:17:50 GMT -5

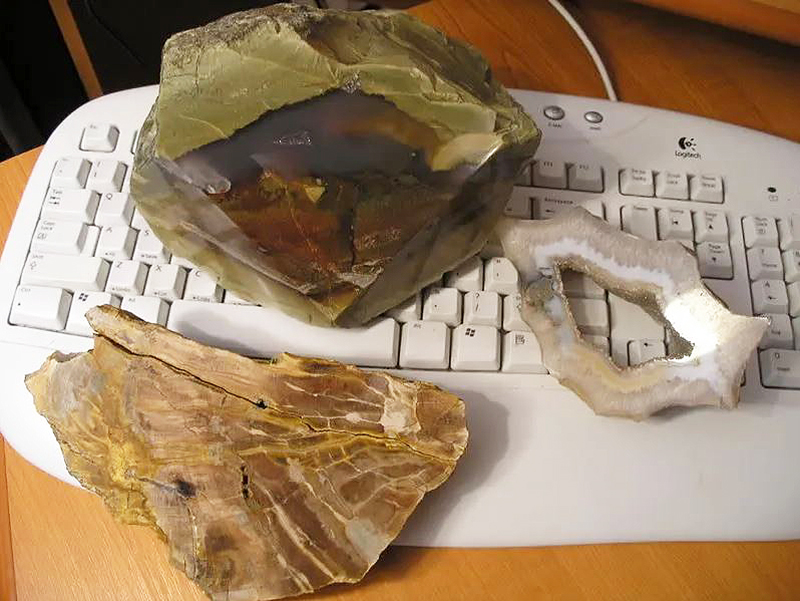

Hi everybody! I've polished some stones these days and had the camera with me. I thought it's not bad to take some photos during my work. Maybe they'll be useful for some of you and maybe some others could give me advices for improving the technique. So, here is my machine I've built. It's a combined saw and flat lap. The power of the motor: 1500 W. The rotation speeds; 750 rot/min the saw, 350 the flat lap.  The whole machine  The flat lap part Some slabs have a little out-of plan area that must be eliminated.  I use for this a diamond resin diamond disk on aluminium support. Don't know the real purpose of this tool, I suppose it's for sharpening and shaping high strength steel tools, but it's great for stones.  Then I use a 400mm steel disk. I spray the disk with water and add some 220 SiC grit to form a paste. i rotate the slab by hand a few, to mix the water and the grit and then start the machine. In a few minutes the scratches from the saw are gone.  After that, I put an 8 mm thick glass disk on the steel disk and repeat the operation with water and 600 grit. During the rotating, some resistance appears but i spray a few water and that decreases the force.  After these two stages, the surface is very smooth and silky, but no shine yet. I do the polishing with some diamond pads stitched on a rubber pad. The pads are 100 mm diameter. I use four pads: 1500, 3500, 10000 and "gloss" pads. After 3500, the shine is clearly visible (and sometimes the scratches, too  especially if the rocks and tools are not very thoroughly washed between the stages)  And, voila! The result of about 3.5...4 hours of work (including preparing and cleaning the machine, and re-sanding and re-polishing the big rock that was initially very scratched)  Thanks for looking, Adrian |

|

|

|

Post by beefjello on Apr 17, 2007 21:48:41 GMT -5

That's very cool Adrian! You "Do It Yourselfers" are in a league of your own! Thanks for sharing that.

|

|

rockinmom

spending too much on rocks

Member since January 2007

Posts: 481

|

Post by rockinmom on Apr 17, 2007 22:13:44 GMT -5

That's very cool..  Tammy |

|

|

|

Post by LCARS on Oct 10, 2007 14:20:50 GMT -5

Adrian, the more you post here the more I see you have some real ingenuity when it comes to your craft. I think it helps to have a bit of good luck on your side and a good eye for seeing different ways things can be used and ways things can be done.  I've used those diamond pads before too for resurfacing marble floors but there were like 8 or 9 of them at a time stuck with Velcro in a sprial on a larger rotating wheel for refinishing floors. The thing I hated was the velcro, it started to throw pads if you didn't keep the pressure even or if you ran over any large or uneven cracks or joints in the floor so you have to constantly stop and chase after them. Looks like you solved that problem with your rig though. I have been wanting to ask you something since you first posted this... In your "the whole machine" picture, I see what looks like a bunch of discs with radial gradiations on them at the middle left side. What are those for?  |

|

|

|

Post by Jack ( Yorkshire) on Oct 11, 2007 0:18:53 GMT -5

Hi

I agree a 100% with Lcars !!

You have a great tallent Adrian ,

Thanks for your posts they are a real inspiration to me and many others ,not to give up but to find the answer, a great machine and system,

Lcars

I think they are his polishing disks as seen in Photo 7

Jack

yorkshire UK

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,774

|

Post by adrian65 on Oct 11, 2007 0:21:06 GMT -5

Thank you, Lcars and Jack.

Lcars, these are the diamond pads, stored (overlapped one over other) and waiting to be used in polishing. I simply put them on one of the threaded shafts that help me keeping the rocks steady while cutting them. When I use them I stick them like in the 7-th photo.

The diamond blade used for cutting is not mounted on the machine, for some reasons it's noisy even if it doesn't cut anything so I get it off while I use the flat lap and the polishing diamond pads.

Adrian

|

|

|

|

Post by LCARS on Oct 11, 2007 0:47:25 GMT -5

That's what I thought they were but maybe it's just the picture, they looked so thin I thought maybe those were adhesive pads or something, thanks!  |

|

stonesnbones

spending too much on rocks

Member since September 2007

Posts: 255

|

Post by stonesnbones on Oct 11, 2007 12:53:23 GMT -5

Now that what I would call the ultimate flat lap.Very novel idea! Brad

|

|

Tommy

Administrator

Member since January 2013

Posts: 12,652

|

Post by Tommy on Sept 14, 2022 11:14:43 GMT -5

*~ bump ~* photos restored.

I'm surprised that this oldie but greatie build got missed when the DIY page was originally put together.

|

|