|

|

Post by Condor on Jan 25, 2009 15:47:17 GMT -5

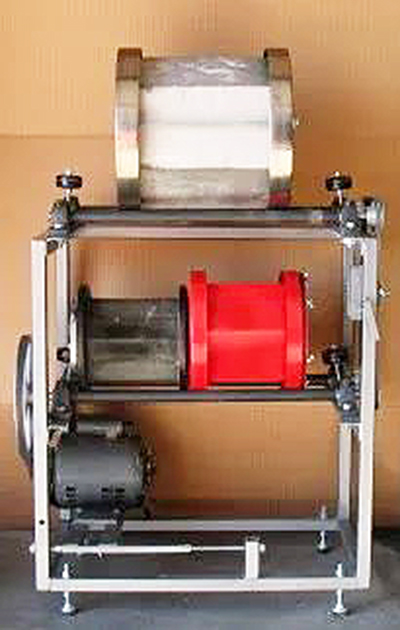

I'd like to give an RTH member a million thanks for the tremendous rock tumbler that he built for me. I am proud to show off his work and most proud to be his friend. Some of you may remember my old 40lb rock tumbler. Except for the barrel and motor, it just died out and fell apart.  Here is my new Chadmanian Rock Tumbler made by Chadman himself.  Thanks Chad. Condor |

|

|

|

Post by Hard Rock Cafe on Jan 25, 2009 16:42:07 GMT -5

Wow! Wish I had a friend like that! Nice work!

Chuck

|

|

chadman

starting to spend too much on rocks

Member since March 2008

Posts: 106

|

Post by chadman on Jan 25, 2009 16:58:58 GMT -5

I think you can increase the lower pulley sizes to get some more speed out of the top rollers for that larger barrel. Go to 3" pulleys maybe. They have to be the same size on both rollers. Hmm. Should work. The local hardware store should have them. The motor mounted no problem? Looks good! i'm going to change out barrels on mine now.

|

|

|

|

Post by Bikerrandy on Jan 25, 2009 18:59:56 GMT -5

Nice! I gotta build one  |

|

|

|

Post by Woodyrock on Jan 25, 2009 20:11:03 GMT -5

Chadman:

I think you just built a better looking machine than any commercially produced. Very nice ly done!

Woody

|

|

NDK

Cave Dweller

Member since January 2009

Posts: 9,440

|

Post by NDK on Jan 25, 2009 22:40:42 GMT -5

Wow! So much tumbling done in a small footprint!

Very nice design!

Nate

|

|

chadman

starting to spend too much on rocks

Member since March 2008

Posts: 106

|

Post by chadman on Jan 25, 2009 23:50:28 GMT -5

Thanks guys. Designed after the idea of my original 8 barrel design. The idea is for it to be a lifetime machine instead of in the dump in 5. I don't like that. I got tired of replacing bushings on my hobby tumblers, so I set out to make a better design. My 8 barrel version going non stop since May of last year. It's here back on page 3. I still don't have 8 barrels going. I have to go to a 1/2 hp motor to do it.

Working on a rotating lap next. Then a sphere machine.

|

|

WarrenA

fully equipped rock polisher

Member since November 2003

Posts: 1,530

|

Post by WarrenA on Jan 27, 2009 0:34:32 GMT -5

"ATTA BOY" Chadman very nice now whats this I hear about a sphere machine

|

|

chadman

starting to spend too much on rocks

Member since March 2008

Posts: 106

|

Post by chadman on Jan 27, 2009 18:48:13 GMT -5

The wheels are always turning. I saw a fellow at a rock show that was selling Diamond brazing rod. Might have been these: www.xmission.com/~ranthon/lapidary.htmwww.xmission.com/~ranthon/BUY/SPHERE-MACHINE-DIAMOND-GRINDING/interesting stuff. I could braze the diamond onto large bell reducers or similar for my sphere cutters. I have one angle motor with cellulose reduction gears that reduces down to 150 RPM I think. If I can find 2 more of those motors making triple head sphere machine should be easy. I'd like to try and run the 3 heads from one motor. I thought about doing it with round pulley belts because you can twist them for different drive angles. Still puttin' a think on it. |

|

NDK

Cave Dweller

Member since January 2009

Posts: 9,440

|

Post by NDK on Jan 27, 2009 20:41:16 GMT -5

Wow Chadman, be sure to keep thinking out loud. I like where your thoughts are heading!

Nate

|

|

|

|

Post by Hard Rock Cafe on Jan 27, 2009 21:17:45 GMT -5

I like his thoughts, too! Gave me an idea for my tumbler. I have a speed reducer...maybe go with direct drive? A little risky for the motor, but I doubt I would get in a situation where a tumbler would jam and stop the motor.

Chuck

|

|

Thunder69

Cave Dweller  Thunder 2000-2015

Thunder 2000-2015

Member since January 2009

Posts: 3,103

|

Post by Thunder69 on Jan 27, 2009 21:49:23 GMT -5

Really nice... I want to build one myself , I am thinking of using sprockets and bicycle chain , figure a way to use the gearing too...never know could be just a pipe dream. one day.

john

|

|

chadman

starting to spend too much on rocks

Member since March 2008

Posts: 106

|

Post by chadman on Jan 27, 2009 22:11:43 GMT -5

I like his thoughts, too! Gave me an idea for my tumbler. I have a speed reducer...maybe go with direct drive? A little risky for the motor, but I doubt I would get in a situation where a tumbler would jam and stop the motor. Chuck I'm gonna start charging! Let's see... a penny for your thoughts is the going price... how many of you are there? ;D Direct drive would work fine if you can get the RPM down to the right speed. The torque on the motor isn't really that much if you are only talking 1-3 barrels. It could be a good way to go. You could use a coupler www.pressureparts.com/ElectMotor-C-Elec-MTR-Coupl-Pressure-Part-336028.aspx |

|

NDK

Cave Dweller

Member since January 2009

Posts: 9,440

|

Post by NDK on Jan 27, 2009 22:26:00 GMT -5

I've wondered why I haven't seen bicycle chains & sprokets used in building tumblers. Does a person want the possibility of slippage or stretching of the belt? Kind of like the weakest link?

Nate

|

|

|

|

Post by Hard Rock Cafe on Jan 28, 2009 12:32:29 GMT -5

Yep. It's already got a coupler on the end that attaches to the motor. Forgot about that.

Chuck

|

|

chadman

starting to spend too much on rocks

Member since March 2008

Posts: 106

|

Post by chadman on Jan 28, 2009 14:26:56 GMT -5

So then alignment isn't too critical. No reason a direct shaft drive won't work as long as you can get the ratio correct. For example, your barrel is 10" in diameter and your direct drive shaft is 1" in diameter and the motor is 150 RPM then you will get 15 RPMs on the barrel. A 3/4" shaft with a 1/8" wall rubber hose over it will make a 1 inch shaft. That's a little slow for me. I like about 30 RPMs.

|

|