Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Dec 2, 2013 19:35:19 GMT -5

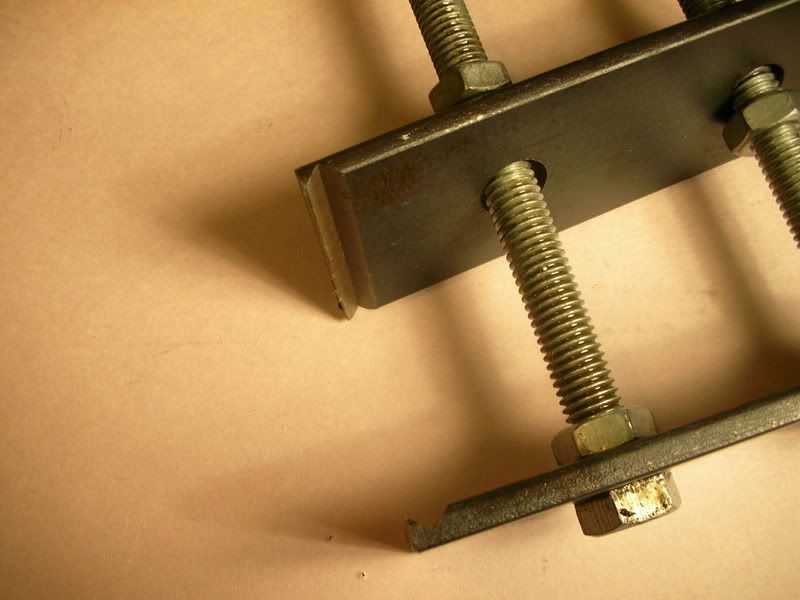

bobby1 - I hope it's OK to use your images here.    Perhaps rockpickerforever will make a short run of the blades for some extra money.

|

|

|

|

Post by rockpickerforever on Dec 2, 2013 20:22:01 GMT -5

Here's a couple links to old RTH posts, re., slabgrabbers. Some repeats of information. forum.rocktumblinghobby.com/thread/54193forum.rocktumblinghobby.com/thread/54930And a link to Sphere Products.com. They sell sphere grinding cups, other sphere making equipment, and also slab grabbers. Edit to add: @shotgunner - Bob was going to make some slab grabbers at one time, actually looked into it. I don't recall what happened, I guess he got busy, and they got put on the back burner? Something I can have him look into again. A friend of ours had asked if we could make a grabber like this - forum.rocktumblinghobby.com/post/600036/thread. He wanted several different sizes for cutting geodes. He had someone make one out of scrap metal for him, and they only charged him like $20 for it. We just can't do it that cheaply inexpensively. Some folks have no idea what it costs to produce something. |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Dec 2, 2013 21:38:45 GMT -5

Have Bob just make the blades of 1/4" grooves milled and holes drilled. Anybody can add screws.

I'd be in!

|

|

Tommy

Administrator

Member since January 2013

Posts: 12,930

|

Post by Tommy on Dec 3, 2013 1:52:11 GMT -5

Now I feel guilty...after first reading this thread and because my saw is a Lortone I ran straight out and bought the Lortone model off Ebay yesterday. Seems like every time I set out to make my own on something like this I end up spending double what I could have just bought it for... |

|

|

|

Post by 1dave on Dec 3, 2013 17:30:17 GMT -5

Personally I prefer at least three (3) points of contact to hold a rock.

I don't want that sucker coming off or moving mid-cut!

|

|

|

|

Post by deb193redux on Dec 3, 2013 17:40:12 GMT -5

Those small little Lortone grabbers are junk. In my opinion. They really only work for half spheres. IF the rock does not taper back for the edge sharply, they let the rock pull out.

Tony's are based on the Large Lortone slab grabber / rock holder. His is small enough to fit in a 10" say - but only those with front-back vise. If you have a top-plate vise, some design where threads/nuts are not on top is needed.

|

|

|

|

Post by Hard Rock Cafe on Dec 3, 2013 17:49:23 GMT -5

I used to use one based on another thread, "no cost slab grabber" forum.rocktumblinghobby.com/thread/15517?page=1, that is very similar to the one made by deb123redux in his thread. I've since switched to the bobby1 design because it's much faster and easier to use. As I mentioned above, I've cranked it down so hard that I've bent the steel, so the rock is not coming out unless it breaks. The rock can come loose or break no matter what device you use; check it before every cut. No need to use a milling machine: an angle grinder works fine to cut the grooves and you can drill the holes with a half inch drill. It ain't rocket surgery, so the tolerances don't have to be exact. Chuck |

|

Tommy

Administrator

Member since January 2013

Posts: 12,930

|

Post by Tommy on Dec 3, 2013 18:19:56 GMT -5

Those small little Lortone grabbers are junk. In my opinion. They really only work for half spheres. IF the rock does not taper back for the edge sharply, they let the rock pull out. I believe you and I’ll probably realize this soon enough BUT it’s got to be an upgrade from my current “glue it to a board” method. Instant gratification I guess…I hate waiting three days for the glue to harden then having it let loose in the middle of the cut. |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Dec 3, 2013 18:25:53 GMT -5

I just realized why I never needed a slab grabber. It's 'cuz when I make slabs I cut them from the 6 faces of the stone leaving behind a cube for me! In my case the byproduct is the keeper! haha

|

|