The Dad_Ohs

fully equipped rock polisher

Take me to your Labradorite!!

Take me to your Labradorite!!

Member since September 2012

Posts: 1,860

|

Post by The Dad_Ohs on Aug 4, 2014 18:08:57 GMT -5

I hate dopping. I have memories being burned by dop wax and the dops keep coming off. The tape in the picture below was recommended and I made some dop sticks. On the other hand, if I work thinner slabs, my fingers take a beating. The good thing about the tape, is it warns you when it is about to come off. It start to get loose rather than coming off suddenly.  [/quote] I still dop some stones, I keep a container of cold water next to me to dip my fingers in to coll them off while working the wax. A popsicle stick works too to move the wax or even a very skinny round dowel. I have also used golf tees in a pin vise with CA glue on it which works very well too. soak in acetone to break loose afterwards. When cutting large rough and working large cabs (very large cabs) I will use Elmer's Wood Glue Max and glue it to 2x4, 4x4, 1x3, whatever size I need for the rough.the diamond saw will cut right through the glue or you can soak it in very hot water to release it. |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Aug 4, 2014 18:39:58 GMT -5

sounds like one of the older craftsmen units where the shaping wheel was used as a saw too, the wheel sat flat and if you wanted to cut sometrhing you laid it flat and cut across. Well sort of, I recall it had a center post or a pin hole that when you either dop or glue the stone onto a pin.. the pin would rest in the pin hole which was slighter away from the black.. and all one would do is turn or rotate the stone etc.. but again this would round the stone only and wasn't any good for actually slab cutting the stone, which I left to others.. I would give them a general size or shape and they'd cut it on a tile saw.. |

|

Fossilman

Cave Dweller

Member since January 2009

Posts: 20,723

|

Post by Fossilman on Aug 5, 2014 9:09:19 GMT -5

I'm running a 14" and need to buy a smaller saw for my fossil cutting,the thinner the blade the better!! My buddy uses a 6" trim saw and he says it's about right for the thin cutting....

Hope to have one by next summer...Thumbs up

I also use the Elmers wood glue for my bigger slabbing,works like a charm.....Liking the ideas on this topic,it's educational...

|

|

|

|

Post by johnjsgems on Aug 5, 2014 11:12:45 GMT -5

A lot of people use a larger saw (thick blade) to chunk rocks down to fit in smaller saws (thinner blades) to reduce kerf loss.

|

|

|

|

Post by stardiamond on Aug 9, 2014 14:46:43 GMT -5

1. Yes, a rock saw blade essentially grinds it's way through the workpiece. Harder you push, more chance of dishing the blade and faster the wear. Patience is good! 2. If the 18 square inch slab was cut on a larger saw, they probably are losing money even without the cost of the rough. That's under 30 cents per sq inch for the cut and for hard jasper, more wear on the blade and a slower cut so more time spent cutting. If the rough was pricy and purchased, even worse. 3. That was a nice looking hunk of starburst. However, it is a rhyolite and often problematic to polish past a satin finish. Therefore , it usually does not demand real high prices. Some rhyolite really drags on the saw blade too as it tends to run dry in the cut due to porosity. I have had some types be real saw stoppers, especially if your blade is not new and very sharp and your oil is dirty. I've got a few starburst slabs in my collection and none were in the "expensive" category. Probably paid less than 50 cents per square inch cut. When I did E-bay, and I did very little, I found it pretty much non profitable except maybe in the instances the material was premium and self collected so my only cost was the cutting. You do have to bear in mind that the larger the blade kerf-wise used to cut your material, the more waste too. I figured my old 20 inch saw ran a blade so thick that I lost one slab from three to the blade kerf....Mel  I was able to get a decent finish except for the starbursts on a cab I cut, but not from this piece. |

|

|

|

Post by stardiamond on Aug 19, 2014 17:06:12 GMT -5

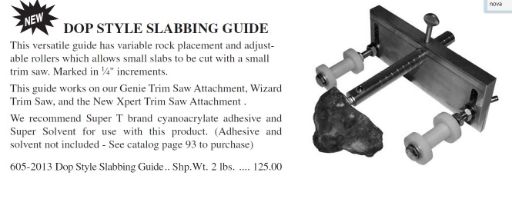

"8" saw with 9" blade" was likely one of the old 9" Highland Park saws. Very common back in the day. Most people run 8" blades in them as the only 9" blade available is really thick. The Genie saw is labeled as "trim saw only, not for slabbing" by the way. The DP catalog shows this for slabbing:  More than I wanted to spend because you would also need to buy another saw table for about $100 delivered if you still wanted to use the Genie for trimming. I ordered the new table and will glue or bolt on a fence so I can even out crooked slabs or trim down thick cabs. |

|

Fossilman

Cave Dweller

Member since January 2009

Posts: 20,723

|

Post by Fossilman on Feb 13, 2017 17:52:08 GMT -5

Going to bump this back into topic......................

|

|