ridvanarik

starting to shine!

Member since May 2015

Posts: 36

|

Post by ridvanarik on May 11, 2016 3:37:21 GMT -5

|

|

70karmann

starting to spend too much on rocks

Member since February 2011

Posts: 190

|

Post by 70karmann on May 11, 2016 11:53:58 GMT -5

Very nice.

|

|

|

|

Post by jakesrocks on May 11, 2016 12:39:21 GMT -5

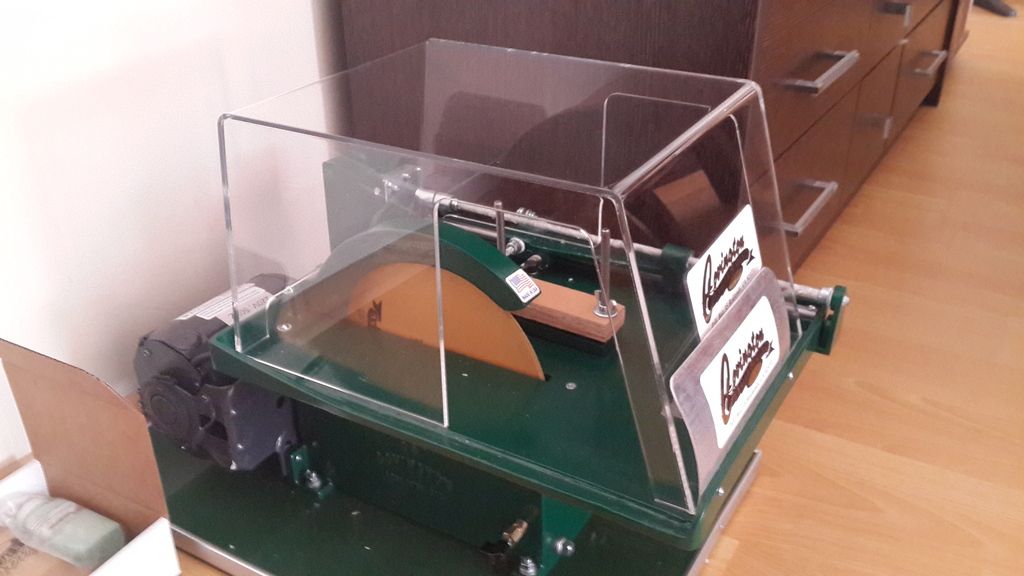

Congrats on the new toy. Now it's time to make it look like a real 10" Covington.  |

|

Fritz

noticing nice landscape pebbles

Member since May 2016

Posts: 77

|

Post by Fritz on May 11, 2016 13:00:08 GMT -5

Real real noice.

|

|

panamark

fully equipped rock polisher

Member since September 2012

Posts: 1,343

|

Post by panamark on May 11, 2016 13:17:28 GMT -5

Never seen one that clean.

And one minute after your first cut, it will be a happy, but dirty saw.

Congrats! You will have a LOT of fun with that.

|

|

sifu

starting to shine!

Member since September 2010

Posts: 35

|

Post by sifu on May 11, 2016 14:38:27 GMT -5

Nice! Soon you won't be able to see through the plastic.  |

|

Sabre52

Cave Dweller  Me and my gal, Rosie

Me and my gal, Rosie

Member since August 2005

Posts: 20,497

|

Post by Sabre52 on May 11, 2016 14:49:06 GMT -5

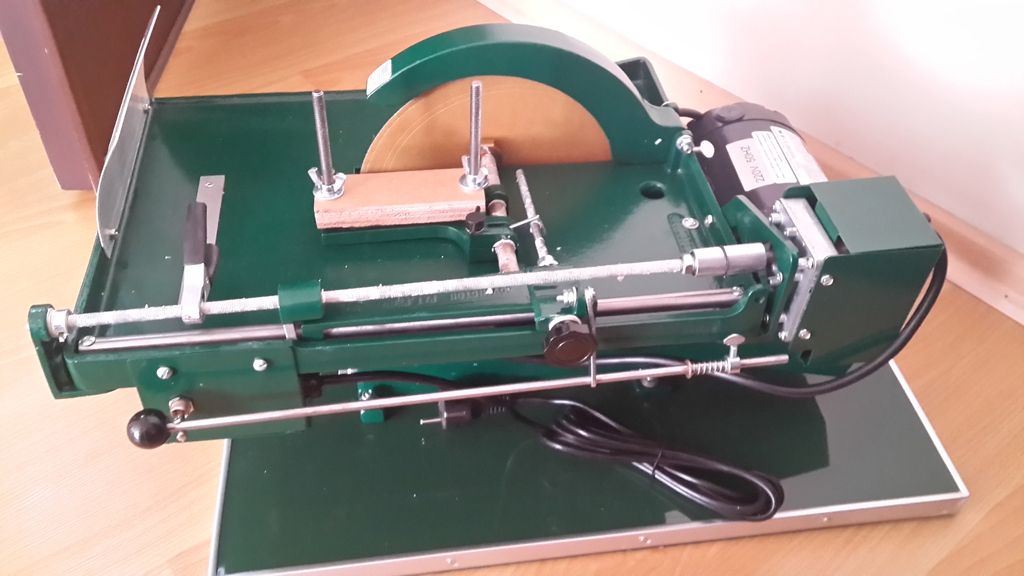

Just heads up. You are going to want to get a cart to mount that on that will catch all the oil, which on that saw ( I own one) flows freely off the table to the floor and everything around it. You will also want to plumb extensions to the clean out drains so you can get something underneath to catch the oil, and you will need a towel or something ( I use a towel and cardboard) to fill the stupid gaps in the hood which allow spray to go all over your shop. The supplied blade is suitable for only cutting softer stones so you need a good blade if you cut harder stuff. If you are where it is hot, the power feed overheats and stalls often and must be allowed to cool down and there is a learning curve to adjusting the clutch. Also, wait till you try to take it apart to clean or change blades if you have normal fingers. (Made for tiny little munchkins with itty bitty fingers) Hate to be a Debby downer but I hope you have more fun with yours than I do with mine. I have found my Covington 10" saw to be quite problematic. Note all the cups, bedpans, spittoons etc needed to catch all the gulldanged oil that wont' stay in the saw *L*....Mel   PS. The plastic handle on the hold down screw will break off right away and make sure to check all the screws on the vice, pully etc as all came loose right off the bat on mine. Extra drive belts on hand are a must too as , when cutting agate etc, a very brief bind up will burn your belt right in half if you are not standing right by the saw and changing a belt is oh so much fun! I have learned to never run this saw unattended like I could with my other old saws. |

|

riverbendlapidary

fully equipped rock polisher

Member since September 2006

Posts: 1,058

|

Post by riverbendlapidary on May 11, 2016 21:17:27 GMT -5

yikes!

|

|

ridvanarik

starting to shine!

Member since May 2015

Posts: 36

|

Post by ridvanarik on May 12, 2016 2:43:55 GMT -5

Thank you very much 70karmann |

|

ridvanarik

starting to shine!

Member since May 2015

Posts: 36

|

Post by ridvanarik on May 12, 2016 2:51:13 GMT -5

Congrats on the new toy. Now it's time to make it look like a real 10" Covington. You're right jakesrocks, it looks a lot cleaner. Toy-like.  |

|

ridvanarik

starting to shine!

Member since May 2015

Posts: 36

|

Post by ridvanarik on May 12, 2016 3:04:03 GMT -5

Nice! Soon you won't be able to see through the plastic.  You're right sifu, pollution is required.   |

|

ridvanarik

starting to shine!

Member since May 2015

Posts: 36

|

Post by ridvanarik on May 12, 2016 3:51:24 GMT -5

Just heads up. You are going to want to get a cart to mount that on that will catch all the oil, which on that saw ( I own one) flows freely off the table to the floor and everything around it. You will also want to plumb extensions to the clean out drains so you can get something underneath to catch the oil, and you will need a towel or something ( I use a towel and cardboard) to fill the stupid gaps in the hood which allow spray to go all over your shop. The supplied blade is suitable for only cutting softer stones so you need a good blade if you cut harder stuff. If you are where it is hot, the power feed overheats and stalls often and must be allowed to cool down and there is a learning curve to adjusting the clutch. Also, wait till you try to take it apart to clean or change blades if you have normal fingers. (Made for tiny little munchkins with itty bitty fingers) Hate to be a Debby downer but I hope you have more fun with yours than I do with mine. I have found my Covington 10" saw to be quite problematic. Note all the cups, bedpans, spittoons etc needed to catch all the gulldanged oil that wont' stay in the saw *L*....Mel   PS. The plastic handle on the hold down screw will break off right away and make sure to check all the screws on the vice, pully etc as all came loose right off the bat on mine. Extra drive belts on hand are a must too as , when cutting agate etc, a very brief bind up will burn your belt right in half if you are not standing right by the saw and changing a belt is oh so much fun! I have learned to never run this saw unattended like I could with my other old saws. sabre52 thank you for the valuable information you gave.  |

|

|

|

Post by orrum on May 12, 2016 8:23:41 GMT -5

Mel that's just incredibly nasty! L9L

|

|

Sabre52

Cave Dweller  Me and my gal, Rosie

Me and my gal, Rosie

Member since August 2005

Posts: 20,497

|

Post by Sabre52 on May 12, 2016 8:41:59 GMT -5

Orrum, Hey it is what it is and that pic was taken not all that long after a good cleaning. Notice how Jake's older Covington has a nice lip on the table. Covington saw fit to eliminate that feature which really screws up the oil retention on the new saws. It's like those folk have never used a rock saw. They've also gone to a double skinny oil tank which has no real function except it is stupid as Hell as it's a booger to get a scoop in there to clean it. The other thing that pisses me off is the table tops on most the old types of ten inch saws used to be hinged so you could just lift them up for cleaning. Now you have to unplug the electric from the power feed and undo several very hard to get to tiny little bolts and remove the whole stinking table top clear off the saw to clean or change blades. Unbelievably stupid stupid stupid!!!!! It's also wise to turn the table top bolts over on the new saw too so it's easier to unscrew and screw. The way they have them set up, it's very hard for larger fingers to get to. Easier to screw on from the top....Mel

|

|

|

|

Post by jakesrocks on May 12, 2016 9:31:04 GMT -5

Hey Mel, mine doesn't have the hinged top, but they used larger screws. A long magnetized screwdriver makes it fairly easy to remove & replace them. Even on the older saws the smaller of the two sumps was too small to easily clean out. And that needle valve is a leaking PITA.

|

|

Sabre52

Cave Dweller  Me and my gal, Rosie

Me and my gal, Rosie

Member since August 2005

Posts: 20,497

|

Post by Sabre52 on May 12, 2016 12:37:02 GMT -5

Jake, Yeah, I miss my old Beacon Star so much. Big oil tank easy to clean with hinged tabletop, huge vice, tons of space in front of the blade and for crossfeed, powerful power feed etc. Could cut really large rocks for a ten inch saw. Hands down, the best slab saw I've ever owned....Mel

|

|

|

|

Post by orrum on May 12, 2016 14:35:13 GMT -5

Yea but Mel I seen a lot of your slabs and that saw sure makes a nice smooth cut!

|

|

Sabre52

Cave Dweller  Me and my gal, Rosie

Me and my gal, Rosie

Member since August 2005

Posts: 20,497

|

Post by Sabre52 on May 12, 2016 14:53:06 GMT -5

*LOL* As I've said, there is a learning curve and a good sharp MK blade has a lot to do with it too...Mel

|

|

Tommy

Administrator

Member since January 2013

Posts: 12,989

|

Post by Tommy on May 12, 2016 16:06:18 GMT -5

Just heads up. You are going to want to get a cart to mount that on that will catch all the oil, which on that saw ( I own one) flows freely off the table to the floor and everything around it. You will also want to plumb extensions to the clean out drains so you can get something underneath to catch the oil, and you will need a towel or something ( I use a towel and cardboard) to fill the stupid gaps in the hood which allow spray to go all over your shop. The supplied blade is suitable for only cutting softer stones so you need a good blade if you cut harder stuff. If you are where it is hot, the power feed overheats and stalls often and must be allowed to cool down and there is a learning curve to adjusting the clutch. Also, wait till you try to take it apart to clean or change blades if you have normal fingers. (Made for tiny little munchkins with itty bitty fingers) Hate to be a Debby downer but I hope you have more fun with yours than I do with mine. I have found my Covington 10" saw to be quite problematic. Note all the cups, bedpans, spittoons etc needed to catch all the gulldanged oil that wont' stay in the saw *L*....Mel PS. The plastic handle on the hold down screw will break off right away and make sure to check all the screws on the vice, pully etc as all came loose right off the bat on mine. Extra drive belts on hand are a must too as , when cutting agate etc, a very brief bind up will burn your belt right in half if you are not standing right by the saw and changing a belt is oh so much fun! I have learned to never run this saw unattended like I could with my other old saws. Haha good lord Mel, I could have written this word for word from the experiences I've had with mine - the exact same model. Within two weeks of getting mine brand new two years ago I became so annoyed at the auto-feed mechanism I stripped every single piece and just use the saw as a push-thru or trim saw. I still have the mechanism if anyone is looking for one - can't swear that all the pieces are there. The saw now resides in a tupperware container that catches the constantly spilling oil - I keep rags around to sop up the oil and keep it from reaching the bottom of the motor which is thankfully 1" higher than the floor of the containment device. The double-reservoir system with a check valve which is supposed to meter the amount of oil flowing into the blade reservoir is a complete bust in my opinion - nobody in their right minds should have the patience to keep that adjusted properly as gunk begins to build up in both reservoirs. Both reservoirs are IMPOSSIBLY small to get my fat hands into for cleaning. I have started using a bucket-head vacuum from HomeyD which has improved the situation a little bit. I have been sorely tempted to bring out an angle grinder and cut channels between the two reservoirs and get some of my sanity back. I have also learned not to even put the screws back in the top plate anymore because it has to be cleaned out so often. Of course with the electrical switch mounted to the top plate even removing the plate is a complete pain in the butt because you have to twist the wiring around and setting it down where it won't drip all over the motor that it is still connected to. I too am sorry for being a Debbie-downer but after using this beast as a trim saw for a year and a half I went out and got myself a 7" Rigid wet tile saw at Home Depot. |

|

Sabre52

Cave Dweller  Me and my gal, Rosie

Me and my gal, Rosie

Member since August 2005

Posts: 20,497

|

Post by Sabre52 on May 12, 2016 17:17:12 GMT -5

*L* Yeah I just leave the check valve wide open all the time as it has never worked well. As I've stated, I swear it's like the saw was designed by someone who has never cut a rock. Thank God their customer service guy is friendly and helpful because we get to talk over the phone a lot. I still use my old Workforce for trimming. Best $100 I ever spent....Mel

PS: I forgot to mention that when I replaced the supplied blade with a good MK blade, I found the slot cut in the table for the blade was not long enough to fit a normal sized MK ten inch blade. Blade would not turn at all. Easy fix with a file but Hell, one would think the makers would have figured someone might want to replace a blade now and then.

|

|