|

|

Post by Garage Rocker on Sept 25, 2017 11:33:34 GMT -5

Mike, we need to go in halfsies on a big saw and find a place to park it halfsies between us! Too many big rocks laying around.  |

|

|

|

Post by Drummond Island Rocks on Sept 25, 2017 11:39:10 GMT -5

Slabbing is slow and most folks don't realize how long it takes to slab a 5 to 6 inch rock all the way thru. My 14" autofeed pretty much runs at 1" every 5 minutes (or less). That means cutting 10 slices in a 6" long rock is 5 hrs of the saw running plus clamping and tending to it every slice. Chuck |

|

|

|

Post by Drummond Island Rocks on Sept 25, 2017 12:12:46 GMT -5

Here is my take on cutting 10 slabs from a 6" long rock. It sounds horrible when you see it in print but if you have a good rock then every half hour you get the treat of checking out a new unique slice.

10:00 clamp rock in saw and start first cut

10:30 Open saw, pull vise back, crank handle ¼”, Put end cut in oil-dri. Restart saw.

11:00 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw.

11:30 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw.

12:00 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw.

12:30 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw.

1:00 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri.

Unclamp rock. Put remaining rock from the vise in oil-dri to soak up excess oil. Transfer all the slabs and remaining rock to bucket of hot water and dawn dish soap. Hand scrub each piece. After completely dry use wood glue to attached remaining rock to a section of 2x4. Let that cure for 5 days.

5 days later ……

10:00 clamp 2x4 with glued rock in saw and start first cut

10:30 Open saw, pull vise back, crank handle ¼”, Put end cut in oil-dri. Restart saw.

11:00 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw.

11:30 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw.

12:00 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw.

12:30 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw.

1:00 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri.

Transfer all the slabs to bucket of hot water and dawn dish soap. Hand scrub each piece.

|

|

|

|

Post by captbob on Sept 25, 2017 12:25:51 GMT -5

^^ LOL yup!

And that is assuming you can get that many cuts from the rock without having to reclamp it in the vise.

I don't think I have EVER gotten 7 slaps from a rock - not sure I have ever tried though. Not being a cabber, I usually cut much thicker slabs.

Regardless, that pile of rocks would (easily) take me a week or more to cut.

|

|

|

|

Post by orrum on Sept 25, 2017 12:57:07 GMT -5

Great post and time study Chuck!!!

|

|

|

|

Post by Drummond Island Rocks on Sept 25, 2017 13:14:25 GMT -5

Great post and time study Chuck!!! Thanks Bill I know all saws are a bit different but that timeline paints a good picture of what is involved. Chuck |

|

Sabre52

Cave Dweller  Me and my gal, Rosie

Me and my gal, Rosie

Member since August 2005

Posts: 20,504

|

Post by Sabre52 on Sept 25, 2017 17:02:58 GMT -5

*LOL* Man, my saw ain't that efficient. Since it's a ten inch, I seldom get more that three slabs without reclamping.

My slabbing goes like this: Move jeep from sawing area and roll out saw.

Spend five or ten minutes getting the nodule solid in the vice, shimmed etc.

Sponge up all the lost oil from the table, the saw shelves etc. Dump various buckets etc that catch all the oil running off the Covington saw table. Dump oil in reservoir.

Cover saw cover with towels, close in holes in cover with cardboard etc. Spend twenty minutes cutting off end of rock.

Crank saw carriage over a quarter inch or so and try to find a spot where the blade will not slip off the nodule.

Cut first slab . Twenty minutes or so. Responge up all the lost oil, empty cups in reservoir etc. Reset carriage and repeat until saw overheats and shuts down. Spend ten minutes cussing aholes that designed the saw. Go have lunch while the power feed cools.

Repeat until blade bogs down and belt slips or clutch cuts out. Unvice rock. Cuss saw some more. Spend another twenty minutes dressing the blade. Revice rock and repeat until I run out of cuss words, or get tired of sponging up lost oil. Not counting eons spent replacing drive belts when I burn them up cause I'm multitasking and not watching he dang saw like a hawk.

Mop up oil off the floor. Return jeep to shop. Wash slabs and set them in sun to dry..Mel

|

|

|

|

Post by captbob on Sept 25, 2017 17:15:37 GMT -5

That sounds like a really fun time Mel !!

WHY don't you get a new saw? Life is too short for such aggravations!

My procedure would add:

Hear saw has quit cutting, go to saw, take a deep breath and open lid.

Quickly leave garage and wait 10 minutes for oil mist to settle so I'm not breathing that crap.

If cutting outside, I can lower the mist settling time to 5 minutes.

ETA: oh, forgot a couple steps.

Unplug saw BEFORE opening hood. So I don't do anything stupid and get an oil bath.

Plug saw back in when I return after oil mist has settled.

|

|

Sabre52

Cave Dweller  Me and my gal, Rosie

Me and my gal, Rosie

Member since August 2005

Posts: 20,504

|

Post by Sabre52 on Sept 25, 2017 23:20:19 GMT -5

Bob, Regarding getting a new saw. This one is my fifth and if you can believe it, not the worst. Loved the 10" Beacon Star till it eventually died. Best saw I ever had. The old HP 10" was not too bad but gravity feed got annoying (I should admit, I'm easily annoyed with machinery). Big 20" HP was cranky and the blades cost too much. Lortone 14" was nothing short of a POS and I actually got so mad at it I took it out in the drive and beat it to death with a sledge hammer ( very satisfying!) Covington 10" is messy, cranky and poorly designed but serves it's purpose. With every saw I've had, I've not been able to safely multi task and I don't like wasting time. Soon as I turn my back on the damn saw, they always manage to eventually screw up and turn fun into dirty nasty work fixing the dang things. May just as well skip the saw and just roll in the dirt, smack myself in the knuckles until bleeding, and raise my blood pressure.

Probably will just sell off all my rough rather than get a new saw after this one, as I've not liked any saw I've seen lately. I've decided I like horses and guns cause I understand them and they are "fun". Seeing what's inside a rock is fun and hunting rocks is fun, but rock saws are "NOT FUN!". I'm too old and cranky to play with stuff that is not fun. Horses and shooters by the way are extremely therapeutic. Make me mellow and relaxed, almost like meditation. Good stuff!!!!....Mel

|

|

|

|

Post by Drummond Island Rocks on Sept 26, 2017 5:34:05 GMT -5

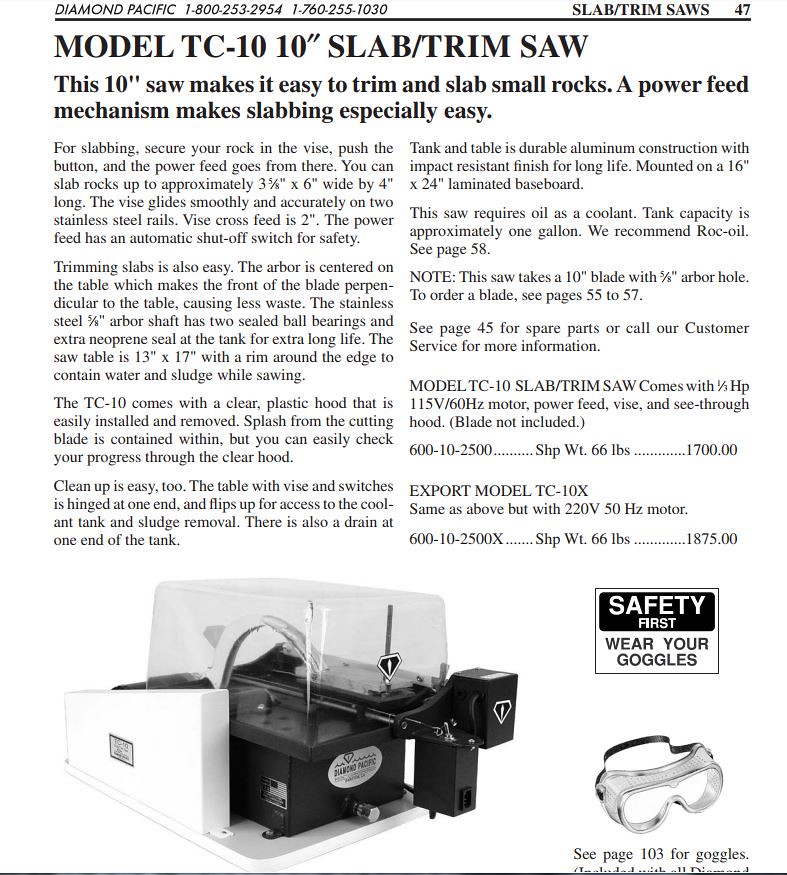

Loved the 10" Beacon Star till it eventually died. Best saw I ever had. My 14" is the beacon star. I would love to find the matching 10" model. Been on my hunting list for awhile. I know this is extremely expensive but isn't it the exact same design as the old beacon star?  Chuck |

|

|

|

Post by adam on Sept 26, 2017 6:47:37 GMT -5

Here is my take on cutting 10 slabs from a 6" long rock. It sounds horrible when you see it in print but if you have a good rock then every half hour you get the treat of checking out a new unique slice. 10:00 clamp rock in saw and start first cut 10:30 Open saw, pull vise back, crank handle ¼”, Put end cut in oil-dri. Restart saw. 11:00 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw. 11:30 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw. 12:00 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw. 12:30 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw. 1:00 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Unclamp rock. Put remaining rock from the vise in oil-dri to soak up excess oil. Transfer all the slabs and remaining rock to bucket of hot water and dawn dish soap. Hand scrub each piece. After completely dry use wood glue to attached remaining rock to a section of 2x4. Let that cure for 5 days. 5 days later …… 10:00 clamp 2x4 with glued rock in saw and start first cut 10:30 Open saw, pull vise back, crank handle ¼”, Put end cut in oil-dri. Restart saw. 11:00 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw. 11:30 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw. 12:00 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw. 12:30 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Restart saw. 1:00 Open saw, pull vise back, crank handle ¼”, Put the slab in oil-dri. Transfer all the slabs to bucket of hot water and dawn dish soap. Hand scrub each piece. I had an issue once where someone used wood glue to attach a few slabs to a plane to cut. After cutting, he left the slabs on that plane with the wood glue and sent em' to me. I was pretty darn happy to have my rocks cut. But, when I tried to remove the few slabs from the plane, well, a couple slabs just cracked into pieces. I think we all need our own slab saw to save the misery of having another person do the job for us, but money issues are in the way, at least on my end. And space issues. |

|

|

|

Post by Drummond Island Rocks on Sept 26, 2017 7:09:14 GMT -5

I had an issue once where someone used wood glue to attach a few slabs to a plane to cut. After cutting, he left the slabs on that plane with the wood glue and sent em' to me. I was pretty darn happy to have my rocks cut. But, when I tried to remove the few slabs from the plane, well, a couple slabs just cracked into pieces. I think we all need our own slab saw to save the misery of having another person do the job for us, but money issues are in the way, at least on my end. And space issues. Maybe on small rocks that would pose an issue but most of the time I am cutting rocks that yield 8-10 slabs. One half of the rock gets glued to a board so the most I can lose is one slab. Half the time there is still no waste. If I get down to the end and there is 3/8" thick still on the board I'll cut a 3/16" slab from that and toss the remaining sliver of rock and wood in the trash. If there is less then 3/16" when I get to the end then that just becomes tumbler food anyway. CHuck |

|

Sabre52

Cave Dweller  Me and my gal, Rosie

Me and my gal, Rosie

Member since August 2005

Posts: 20,504

|

Post by Sabre52 on Sept 26, 2017 8:05:53 GMT -5

Chuck, Except for the lid, that saw does look a lot like my old Beacon Star. Man problem I've encountered is the use of so many questionable parts these days. Power feeds do not work nearly as well as in the old models. Don't know of the one on that "very expensive...Wow!", saw is any different than the one that gives me fits on my Covington. Hot here in Texas and that overheating thing is a real issue. Beacon Star never had a problem but the Covington really does. Scots in my blood really rebels at the thought of paying $1700 plus shipping for any ten inch saw no matter how well it works. Have to cut a whole lot of rocks to make that one pay off....Mel

|

|

|

|

Post by Drummond Island Rocks on Sept 26, 2017 8:13:10 GMT -5

Chuck, Except for the lid, that saw does look a lot like my old Beacon Star. Man problem I've encountered is the use of so many questionable parts these days. Power feeds do not work nearly as well as in the old models. Don't know of the one on that "very expensive...Wow!", saw is any different than the one that gives me fits on my Covington. Hot here in Texas and that overheating thing is a real issue. Beacon Star never had a problem but the Covington really does. Scots in my blood really rebels at the thought of paying $1700 plus shipping for any ten inch saw no matter how well it works. Have to cut a whole lot of rocks to make that one pay off....Mel Yep too rich for my blood. Glad I found the beacon star used at a great price. The diamond pacific copy of the beacon star 14" costs $2,900 and that is with no blade. I did call Don at DP and he said almost all of the parts are interchangeable with the old beacon stars though. I was going to buy a new arbor assembly but it ended up being cheaper to get a new shaft made at machine shop. Chuck |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Oct 8, 2017 17:54:29 GMT -5

Bill at DP is the shit. Love that guy!

|

|

fishnpinball

Cave Dweller  So much to learn, so little time

So much to learn, so little time

Member since March 2017

Posts: 1,491

|

Post by fishnpinball on Oct 8, 2017 18:43:49 GMT -5

There is a reason slabs for sale cost much more than rough and the really nice slabs command a premium.

|

|