mibeachrocks

starting to spend too much on rocks

Member since September 2013

Posts: 198

|

Post by mibeachrocks on Oct 18, 2013 9:08:10 GMT -5

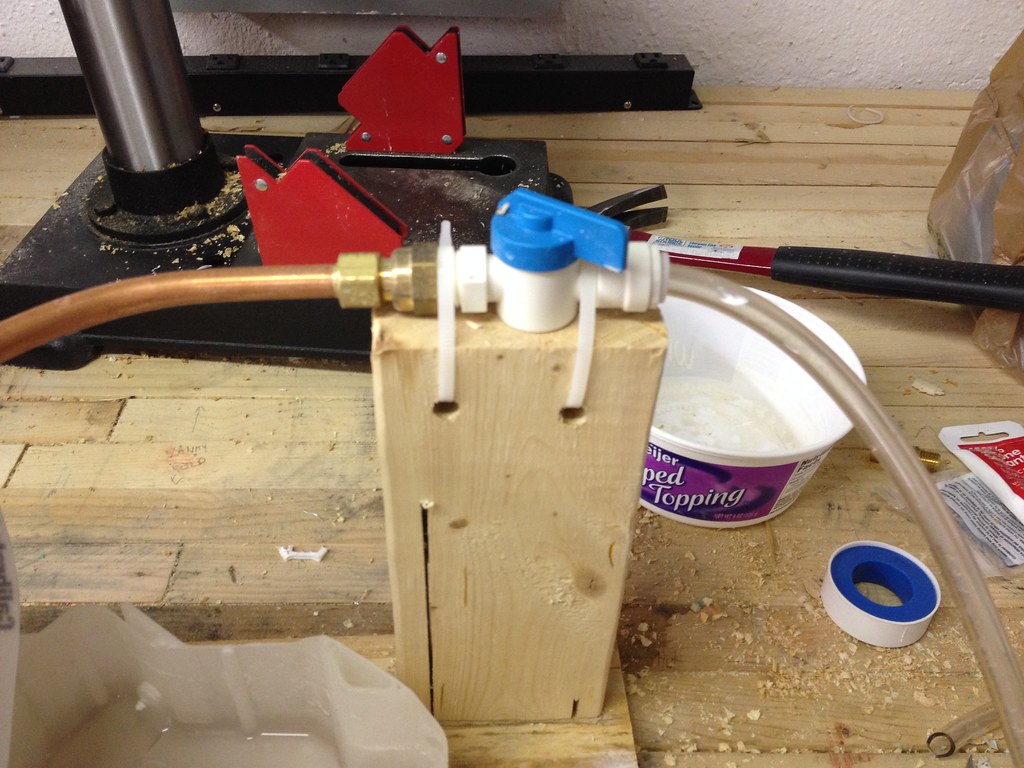

I've finally completed my own vertical flat lap machine. I mostly polish Petoskey stones and got really tired of the sandpaper method. The concept is based on jamesp's slab polisher and Jugglerguy's method for polishing Petoskey. While I enjoy rocks and fossils, the cost of equipment can be a bit high for those starting out. I figure this contraption should do for now. Most of the materials (except the diamond pads) were scap materials. Overall is cost me less than $100 including diamond pads. Even is all of the materials were purchased, it would cost less than $200.  Material List 1. Old B&D 3/8" drill 2. GFCI receptacle (a must) 3. 15 amp switch 4. 14 gauge extention cord 5. various sizes of tubing 6. Copper tubing 7. Collection pan is the cover from a washing machine motor. 8. Spray guard is a paint bucket from ACE 9. Diamond pads and backing plate are from McGills 10. water pump from my tile saw Vibration from the unit can be an issue, but I learned to take care of that by adjusting the speed of the drill. There is still a bit of splashing but probably not as much was with jamesp.      |

|

|

|

Post by pghram on Oct 18, 2013 9:47:38 GMT -5

Nice rig, where there's a will there's a way, even when funds are low.

Rich

|

|

|

|

Post by jakesrocks on Oct 18, 2013 11:17:35 GMT -5

That'll get-r-done. Been a while since I've seen a pair of those magnetic welding clamps. Need to dig mine out.

|

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Oct 18, 2013 11:47:39 GMT -5

I use the same pads but I have a much different set up. At first I recycled my water too but when I got to watching the suggestions on here I found out that if you recycle the water you are also recycling the grit, especially if you have a pump sitting on the bottom of the bucket. You can eliminate a lot of the grit being pumped back up is to raise the pump up off the bottom of the bucket. It takes more water hauling but if you pumped from one bucket and drained into another you would not have any grit contamination. I finally went to a half bucket sitting up on a shelf and gravity feeding the water. I don't know if I can tell any difference but if you notice any new scratches showing up that is probably the problem.

I love home made even if I have the money to buy the manufactured stuff. It is kind of like snubbing my nose at the over priced stuff they sell. I really like your setup and I know that you are going to have a lot of fun with it. Those pads work really well and later on if you speed up the rpms with a different set up they will work much faster. I am turning mine at about 2000 rpm. Much more water spray though.

Jim

Jim

|

|

mibeachrocks

starting to spend too much on rocks

Member since September 2013

Posts: 198

|

Post by mibeachrocks on Oct 18, 2013 14:46:51 GMT -5

Thanks for the comments and suggestions. I will definately prop up the pump to keep it out of the mud.

jakesrocks, that is the problem when you have a harbor freight a few miles from your house. While the quality of their stuff is not always the greatest, you can pick up cheap items like those clamps for $1 on sale.

|

|

|

|

Post by jakesrocks on Oct 18, 2013 21:52:49 GMT -5

LOL. That's where I got mine when I lived in California. I could be at their store in about 8 minutes. Gotta drive about 6 hours to get to a store now.

I've got a little 1/8 HP 2 speed motor that would be ideal for grinding softer materials like Petosky stone. It's dual shaft. I used to use it with a couple of small buffing wheels.

|

|

|

|

Post by roy on Oct 19, 2013 12:15:35 GMT -5

kool set up !everyone has to start some were and you have a crafty mind i see something bigger in your future!

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,663

|

Post by jamesp on Oct 20, 2013 17:32:55 GMT -5

|

|

mibeachrocks

starting to spend too much on rocks

Member since September 2013

Posts: 198

|

Post by mibeachrocks on Oct 21, 2013 8:49:19 GMT -5

Thanks for mentioning that jamesp. I purchased the drill adapter from McGills without realizing the drill that I was going to use was a 3/8" and not a 1/2" chuck. I tried finding cheaper ways around purchasing a new adapter but in the end, I ended up ordering a core bit adapter from Sears.

|

|

|

|

Post by 1dave on Oct 27, 2013 10:32:37 GMT -5

Neat ideas. A lot easier than trading a kidney for a combination unit.

Thanks for sharing!

|

|

mibeachrocks

starting to spend too much on rocks

Member since September 2013

Posts: 198

|

Post by mibeachrocks on Oct 29, 2013 13:45:09 GMT -5

I ran into a problem over the weekend. I was running a petoskey stone through the diamond pads (100, 200, 400, 800, 1500, 3000). Everything was progressing very nice until I got to the 1500. Scratches that were not visible before were all of a sudden showing up after I ran it through the 1500. I started over at 200 again to only have it happen 2 more times. After a bit of detective work, I found that it was the 800 pad that was defective (you get what you pay for I guess). As luck would have it, my local Woodcraft retail store was having an event. I had to pick up some other sanding supplies and decided to try the Mirka Abralon sanding pads. They are silicon carbide, padded and have a velcro backing. They are suitable for wet/dry uses. I picked up a pack on sale (@ $10 for 2 pads) and gave them a try in place of the 800 diamond pad. They worked great. Now to see how long they last.

|

|