jamesp

Cave Dweller

Member since October 2012

Posts: 36,583

|

Post by jamesp on Jan 3, 2014 20:47:19 GMT -5

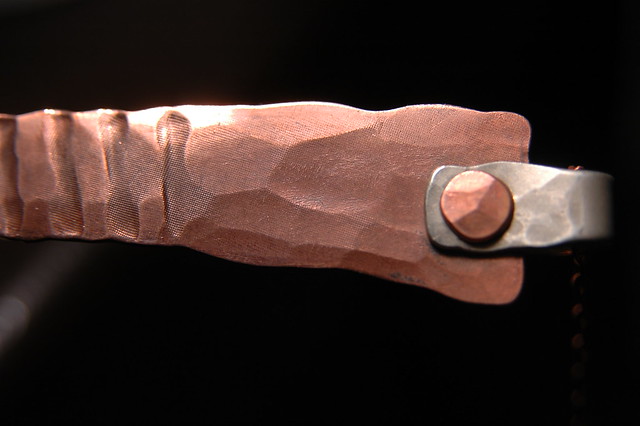

I finished 2, but got 10 more in process. Those are 1/16" rivets of brass, copper and stainless. Not through w/finish and jump ring provisions. Stainless rivet has a defect. It's been a while so i am a little rusty. The style is industrial/Sci Fi. Out of a german silver hotel tray circa 1940.  This one out of silver plated yellow brass 'Rogers & Co' serving tray.  |

|

|

|

Post by Pat on Jan 3, 2014 22:48:57 GMT -5

Those would make neat belt buckles. I'm still in the market for an old tray. Great idea!

|

|

|

|

Post by rockjunquie on Jan 4, 2014 0:02:19 GMT -5

Hey! I really like those. They have a kinda 50's sci fi look. Very cool.  |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,583

|

Post by jamesp on Jan 4, 2014 0:04:58 GMT -5

You will play w/a vintage tray one time Pat. And you will be changed. I can tumble them longer to get more of the silver plate off. Or you can leave the silver

plate on and buff the edges and have bicolored edge. Never did a buckle. Do you have Goodwill stores? A store where people salvage stuff. People get lazy

and get rid of silver plate due to it's required maintenance.

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,583

|

Post by jamesp on Jan 4, 2014 0:10:37 GMT -5

Hey! I really like those. They have a kinda 50's sci fi look. Very cool.  I have been selling those and similar in urban Atlanta for a good while Tela. I love the hammer and anvil. It is similar to doing body work-hint hint. It takes very little filing, sanding and cutting because a smooth anvil and hammer leaves a great finish. And most of the urban customers do not want them polished, but dull... They like the weight too. Feels like a real slab. I have sold them as warts, disease, guts, etc. Sci fi like that kind of talk. |

|

|

|

Post by 1dave on Jan 4, 2014 10:17:17 GMT -5

Forging! That is a topic missing 'till now from this section. jamesp so glad you are around to brighten these pages! |

|

Tom

fully equipped rock polisher

My dad Tom suddenly passed away yesterday, Just wanted his "rock" family to know.

My dad Tom suddenly passed away yesterday, Just wanted his "rock" family to know.

Member since January 2013

Posts: 1,557

|

Post by Tom on Jan 4, 2014 19:17:06 GMT -5

Excellent work James, they look cool

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,583

|

Post by jamesp on Jan 4, 2014 21:16:25 GMT -5

Hammer plate and polish to desired effect

Drill 1/16 holes (no deburring required)

Stick the solid rivets in the holes.

Electricians side nippers to cut the shanks off

Hammer rivets and nipped shank nubs to desired effect

Got 1/32 1/16 3/32 1/8 5/32 and 3/16 rivets in stainless copper brass

Purdy easy

Can use round heads, beveled, hollow, attach layer(s)

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,583

|

Post by jamesp on Jan 4, 2014 21:29:43 GMT -5

Pounded a sacrificial (not annealed) copper wire into this 1/8" 308 stainless w/3 pound hammer. Tremendous impacts required and wore hearing protection. Yee haa!! Watch finger tips. Several rivets and tripoli polish on a 1 HP eight inch grinder buffing pad. Extreme heat generated by buffing. Probably should use 1200 then tripoli. Buffing pads in 12 packs at Northern. They wear out....  |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,583

|

Post by jamesp on Jan 4, 2014 22:45:33 GMT -5

|

|

|

|

Post by connrock on Jan 5, 2014 7:16:02 GMT -5

Pretty cool!

I love stainless steel about as much as I hate it! LOL Terrible stuff to work with!

connrock

|

|

Tom

fully equipped rock polisher

My dad Tom suddenly passed away yesterday, Just wanted his "rock" family to know.

My dad Tom suddenly passed away yesterday, Just wanted his "rock" family to know.

Member since January 2013

Posts: 1,557

|

Post by Tom on Jan 5, 2014 9:09:41 GMT -5

A nice or different finish for stainless is to sand blast it. Its kind of a matt finish and what looks even better is a coat of clear coat paint over it. If you have a sand blaster in your shop James you might give it a go.

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,583

|

Post by jamesp on Jan 5, 2014 9:44:34 GMT -5

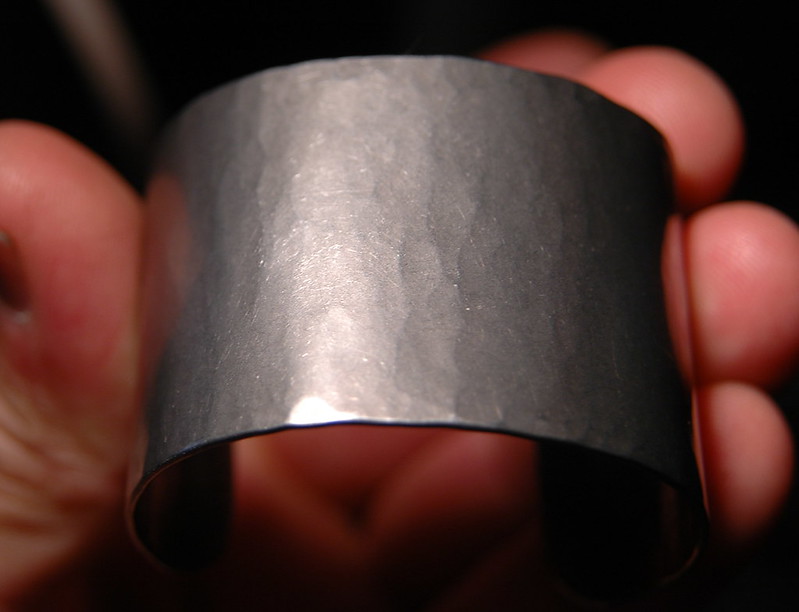

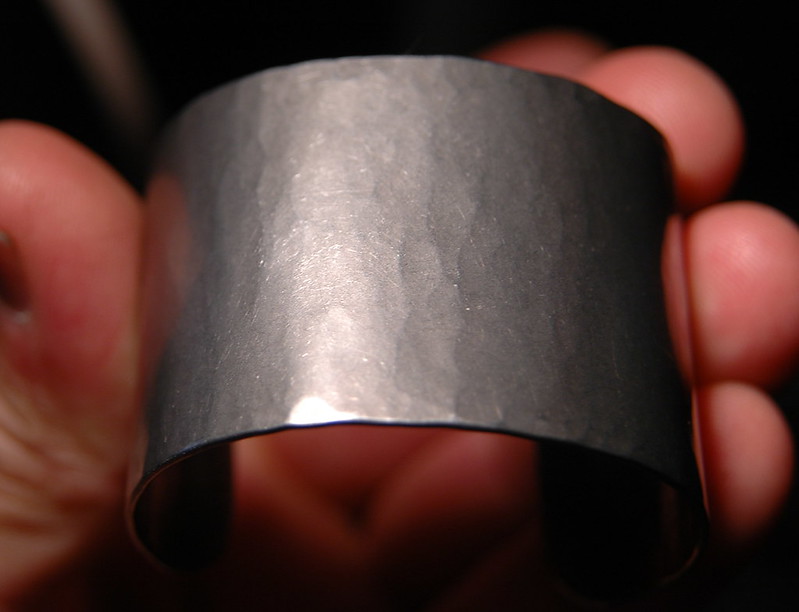

Pretty cool! I love stainless steel about as much as I hate it! LOL Terrible stuff to work with! connrock Stainless is a monster. Old 18 8 can be much friendlier since it is softer(not soft but softer). The stainless rivets are way harder than the copper and brass making them not behave like the softer metals. I get a big grin on my face when i manipulate it with the arc welder. It melts like butter and leaves shiny melted beads for weird effects. I just shear them up and basically melt the edge eliminating deburr process. Question is can you get rid of the burrs. They are stubborn. I found 1 5/8" wide stainless shim stock about .030" thick at the junk yard. They were machine shims. Cut em to length and radius ed the corners and mass tumbled them. Check out the hammered surface   |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,583

|

Post by jamesp on Jan 5, 2014 10:01:38 GMT -5

The sand blast sounds like a great idea Tom.

I get a few finishes out of the tumbler.

I would love to get a sand blaster after it.

Anything to punish the stainless.

Punish the stainless....

|

|

Fossilman

Cave Dweller

Member since January 2009

Posts: 20,715

|

Post by Fossilman on Jan 5, 2014 10:35:56 GMT -5

Nice work James!

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,583

|

Post by jamesp on Jan 5, 2014 11:24:53 GMT -5

Thanks Micheal.

|

|

|

|

Post by rockjunquie on Jan 5, 2014 20:25:10 GMT -5

More great pieces. Stainless is really popular for jewelry. I bet those cuff bracelets are popular.

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,583

|

Post by jamesp on Jan 5, 2014 22:31:10 GMT -5

The stainless is popular and some people can be sensitive about other metals. They do not normally complain about stainless. But it is a difficult metal to work with as it is hard and tough.

Other than forming or melting it i steer clear from it. It even takes forever to tumble the burrs off of it. But once you have completed a piece out of it about nothing can hurt it.

|

|

|

|

Post by talkingstones on Jan 6, 2014 6:54:39 GMT -5

James, I'm really liking your stuff. You've almost got a steam punk look going with these and I like what you're doing with them!!! Definitely different but different is good!!!  |

|

|

|

Post by connrock on Jan 6, 2014 8:28:11 GMT -5

You are one ambitious guy doing a hammered finish on stainless! It came out great though! LOL My right shoulder and arm are in such bad shape I have all I can do to get a hammered finish on annealed copper now! LOL My wife just requested a Red Sox logo piece done in repousse and chasing on copper and I have to put it off till I can swing that heavy 4 oz hammer! LOL Here's one I did a while back,,,,,6" diameter,,,,  connrock |

|