choochoorocks

starting to spend too much on rocks

Rock hounding

Rock hounding

Member since April 2020

Posts: 181

|

Post by choochoorocks on May 17, 2023 23:44:59 GMT -5

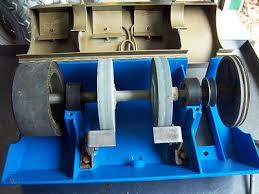

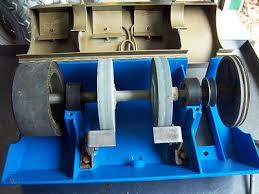

Hi guys, I acquired an old Star Diamond cabbing / trim saw combo machine several months back and plan on restoring it. I'm not very handy, so this is quite an interesting/fun challenge for me. This is how it looks like (motor in back):  Eventually, I'm going to have to mount the motor on the wooden board and change out the belt. Right now, I'm mainly focused on cleaning it out. I have several questions about this machine, and I think you guys should be able to help! First of all, the wheels look like this (see below). Are these silicon carbide wheels? The surface of the left wheel seems somewhat broken in some places; is it still usable?  With such a machine with only two wheels, is the idea that the two wheels are sufficient preparation to then go on to the polishing stage? The polishing pad looks like this. No doubt I'm going to have to change it out.  And here is how the saw blade and reservoir looks like:  I had to drill out one of the screws to take the top off the trim saw. I plan to replace the blade too, since it is completely rusted. I haven't been able to budge the nut. I've watched a YouTube video on how to do it. Hope it will work! Thanks in advance for your advice! |

|

|

|

Post by Peruano on May 18, 2023 6:07:05 GMT -5

You have a challenge, but it will be a learning experience and probably successful. First while you might be able to use the silicon carbide wheels (DON'T). When you abuse them they break off (throw off) pieces and once out of balance can literally disintegrate hurling lethal chunks of stone at the operator. When using these wheels its essential to spin them to remove excess water before turning off the machine, and more importantly not stand in front of them when you first turn the machine on. Diamond wheels or expando wheels are cheap enough that only in special cases would I recommend sticking with sic wheels.

That rust will be a challenge. Do you know about Evaporust. I hear its wonderful. Don't fret replacing the blade, I'm hoping that you don't have to replace the shaft. I believe the housing is cast aluminum or at least not steel. Hence it is subject to breakage and hard to repair once broken. As you are freeing bearings etc. be cautious not to hammer or pry on the housing. Evaporust shouldn't harm it. I could tell you why I know breakage can be a problem, but you can guess. I have an older cab machine quite similar but without the saw.

Go slow and clean that rascal up and polish rocks. Oh, you do need more than two wheels eventually but I don't want to scare you now.

|

|

|

|

Post by Rockoonz on May 18, 2023 6:28:34 GMT -5

I would keep that blade nut wet with a penetrating oil for at least a day and wire brush everything you can off of the end of the shaft before attempting the removal.

Like Tom said, the SiC wheels are dangerous, I have a scar from a piece of grinder wheel on my chin from an incident at work years ago.

|

|

|

|

Post by stardiamond on May 18, 2023 20:37:14 GMT -5

This is my star diamond machine aka the beast. I bought a bunch of old equipment from a local lapidary guy. It came with two very worn diamond wheels. The wheels had cup spacers against the wheels which were probably for the original silicon carbide. The process was to use the 80 grit and 220 grit to shape and a lapidary belt sander with a worn 400 grit belt and then finish with tin oxide on the leather pad. Some cabs came out ok and others undercut. I was enjoying the hobby enough to buy a Genie. I later decided to retrofit the stardiamond with new 8 inch 80 and 220 hard diamond and 280, 600 and 1200 Nova wheels. I would finish the cabs on the Genie. Thew picture doesn't show it but I bashed a hole in the face so I could slide in trays and use geysers instead of overhead drip. |

|

choochoorocks

starting to spend too much on rocks

Rock hounding

Rock hounding

Member since April 2020

Posts: 181

|

Post by choochoorocks on Dec 18, 2023 16:31:48 GMT -5

This project has taken a long time. I did get a new blade and got the motor hooked up and have the saw working. Now I'm working on replacing the wheels.

I was able to get the bearings off, but so far no luck on the flat polishing disc. Its grub screw (is that what you call it) won't turn despite repeated applications of Kroil. Any ideas?

Also, are any special tools or techniques required to remove the remaining things on the shaft? Are they all simply held in place by grub screws so that a hex screwdriver is all I need, and I can just slide things off once loosened? Everything seems really tight and I'm afraid of breaking something.

|

|

|

|

Post by stardiamond on Dec 18, 2023 19:03:03 GMT -5

I assume this is the same machine with diamond belts on the left for the other grits. I had the same on my machine and replaced with wheels. |

|

choochoorocks

starting to spend too much on rocks

Rock hounding

Rock hounding

Member since April 2020

Posts: 181

|

Post by choochoorocks on Dec 18, 2023 19:22:59 GMT -5

I assume this is the same machine with diamond belts on the left for the other grits. I had the same on my machine and replaced with wheels. Is it just a matter of loosening grub screws and sliding parts off the shaft by hand? Or will I need any special tooling? |

|

|

|

Post by stardiamond on Dec 18, 2023 19:32:23 GMT -5

Mine had already had the two silicon wheels replaced with diamond. My polishing pad was on the left. I removed the arbor, removed the pad by loosening the set screw and slid everything of the shaft. I replaced the wheels and added spacers so the bearings stayed where they were.

|

|

rockbrain

Cave Dweller

Member since January 2022

Posts: 3,201

|

Post by rockbrain on Dec 24, 2023 11:05:48 GMT -5

Sometimes heat can help by expanding the parts. Be careful if using a torch on parts soaked with a petroleum product! A lot of times it's more than rust holding it. You probably don't have a flat spot on the shaft. It only takes a small burr on the shaft to make the close tolerance parts very difficult to separate. As Lee Rockoonz said make sure the shaft is clean. I like to use emery cloth on the exposed parts of the shaft before removing anything. Nothing more frustrating then to get the stuck part free only for it to get stuck again! There's a lot of different penetrating oils available. I've had the best luck with dark thread cutting oil. A plus is that it's way cheaper than most products available. I don't know if it's the chlorine in it or something else but I've found it to be very effective. |

|

|

|

Post by Rockoonz on Dec 24, 2023 14:15:53 GMT -5

rockbrain chlorinated oils and solvents are super effective, but should be followed up with a good rust inhibiting oil since chlorine encourages rust, even when it's in a petroleum product. I had a running argument with my chemist boss about the way rubber molds used with neoprene (chlorinated rubber) rusted even after being sprayed with WD40. He said the WD helped, I disagreed. To prove my point I bead blasted some new steel, a piece of HR bar cut in half, sprayed one liberally with WD and nothing on the other, labeled them and put them outside in a place where they would not be rained directly on, only humidity. Forgot to check them till about 90 days, when I found both rusted. The untreated one had an even thin rust layer, the WD coated one was beginning to develop pits.

|

|

flyingweisel

off to a rocking start

Member since April 2024

Posts: 10

|

Post by flyingweisel on Apr 22, 2024 0:02:15 GMT -5

|

|

choochoorocks

starting to spend too much on rocks

Rock hounding

Rock hounding

Member since April 2020

Posts: 181

|

Post by choochoorocks on May 11, 2024 0:15:51 GMT -5

Should have updated this thread. I got mine all fixed up and it is working well. Last thing to do is to attach a leather pad to the side disc. I replaced both silicon carbide wheels and the 6" blade with new ones.

I actually got a bunch of help from my father-in-law, who worked on it when I wasn't looking, so I don't know everything he did. Getting the wheels off was really tough, but he managed it somehow without special tools.

We oiled the bearings with bicycle oil.

|

|