Mark K

Cave Dweller

Member since April 2012

Posts: 2,818

|

Post by Mark K on Aug 26, 2023 10:25:16 GMT -5

You know how the vice wants to turn to the inside right when the rock can't be placed fully in the vice?

Well, I do and for some reason, nothing I do to block it up seems to work to my satisfaction. I just made a new jaw pad and don't want to have it eaten up like the first one.

Can someone who really knows his stuff make up a proper tutorial on the correct way to block the vice up?

|

|

|

|

Post by Rockoonz on Aug 26, 2023 12:17:42 GMT -5

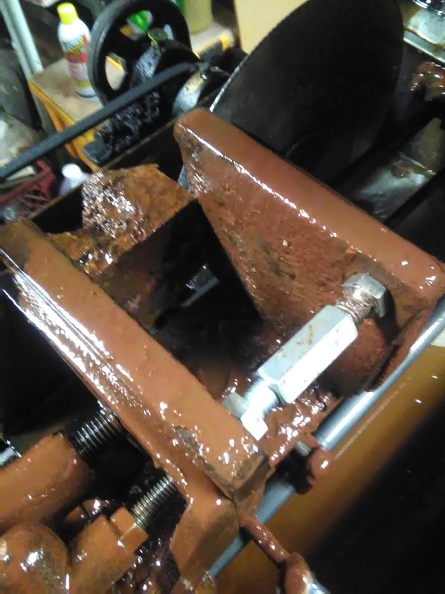

I assume you are talking about keeping the jaws parallel. Here's what I do, learned it from a real machinist who also worked in the club shop back when I was there. I call them jaw jacks. I use 1/2"-13 coupler nuts and an assortment of bolts. They can be fine tuned with one hand while holding the rock with the other. Not shown in these old pics is the twisted bits of hanger wire I added to allow them to stay put if I also need to add wedges to the rock to get it tight.  Here's a couple plus one I built into a vice jaw. The built in one was too much trouble to work. They need to be cleaned periodically, I usually do it when I have the pressure washer out.  Here is the horizontal bar vice modification. On this saw I can flip something I'm cutting and get it so close that the last slab in the vice is good enough to use, just like a slab grabber.  Even with these, it is still good, especually with the HP and FranTom vices, to give the sliding part of the vice a few light taps with a hammer and tighten the vice again to make sure it didn't get bound up anyway. One of these days I'll make a video of that. |

|

|

|

Post by Rockoonz on Aug 26, 2023 12:26:47 GMT -5

Oh, and jaw pads are replacement items, I have found that Oak boards work best for that, red or white oak. Hard enough to last awhile but soft enough for the rock to dig into it just enough to hold it good. I used to keep lath strips to crush between jaws and rock for really tough ones, but now I just cut them in half best I can, then degrease them and gorilla glue them to cut board ends.

|

|

Mark K

Cave Dweller

Member since April 2012

Posts: 2,818

|

Post by Mark K on Aug 26, 2023 15:25:22 GMT -5

|

|

rockbrain

Cave Dweller

Member since January 2022

Posts: 3,172

|

Post by rockbrain on Aug 26, 2023 16:26:30 GMT -5

The jaw jacks are great idea! When I got this new saw I cut a bunch of different length 2x4 blocks to take up the slack plus a bunch of wedges. Something about the vice in this HP I haven't used a block a single time and I've been cutting a lot of small rocks. I use wedges around the rock but nothing on the empty side of the vice. When I mentioned it to John Rowland he said it was because of the tightening screw being offset to the right. I will definitely be making up some jaw jacks for my 24 though!

|

|