earthdog

Cave Dweller  Don't eat yellow snow

Don't eat yellow snow

Member since June 2006

Posts: 2,731

|

Post by earthdog on Jan 24, 2006 23:17:39 GMT -5

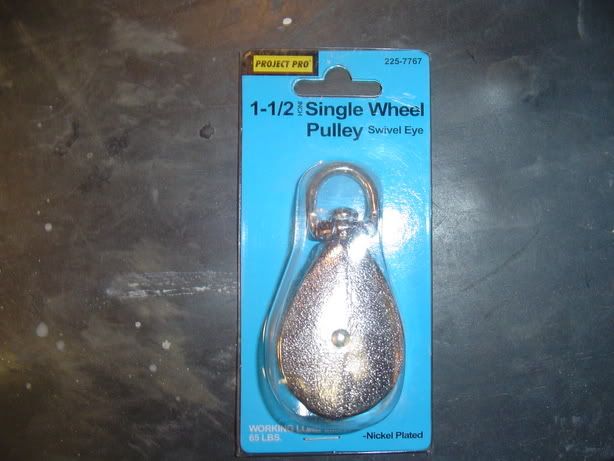

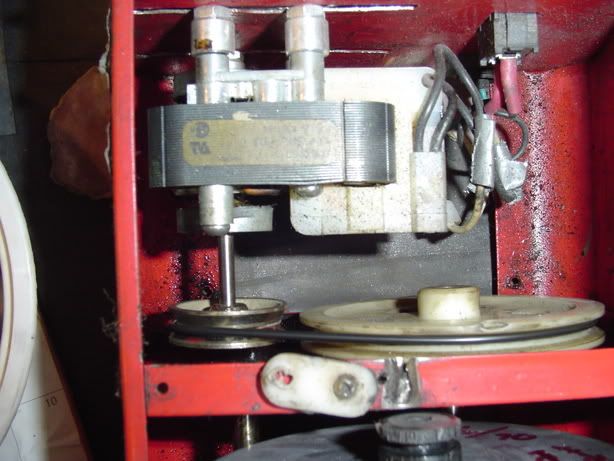

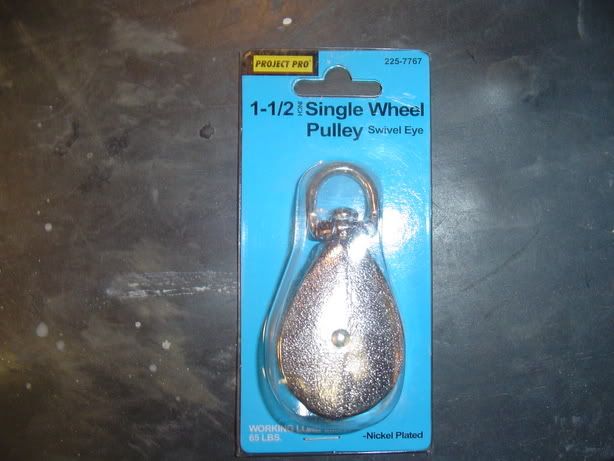

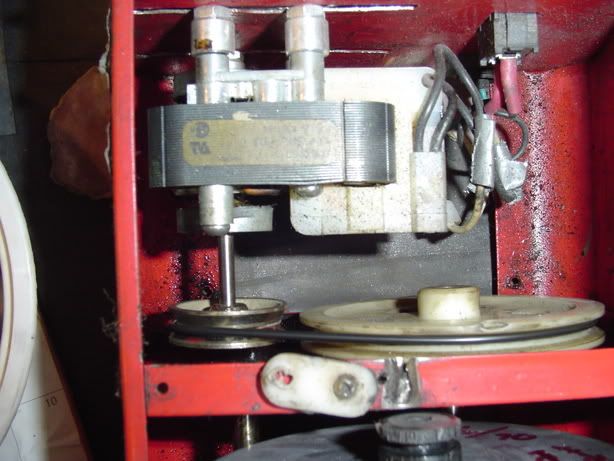

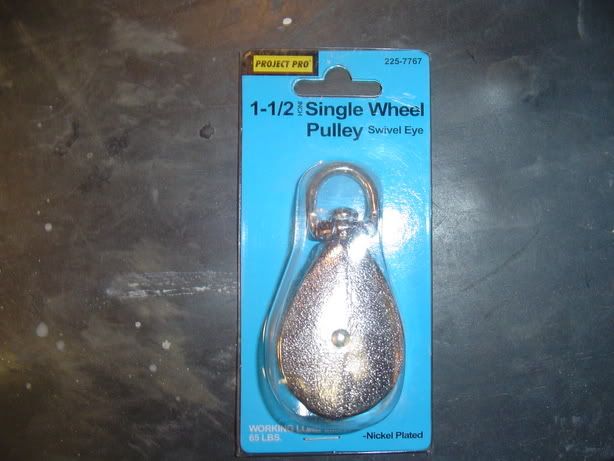

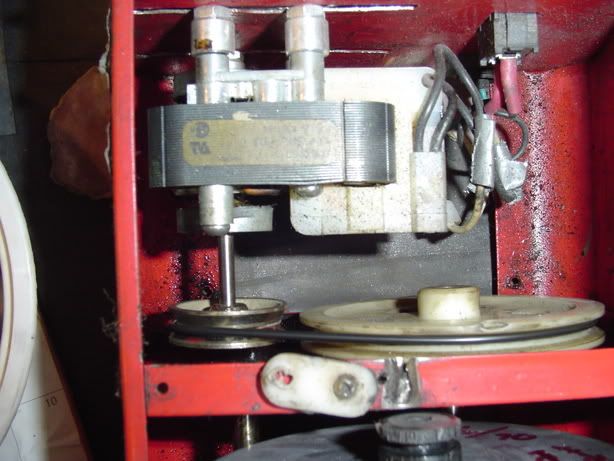

All of the tumblers I have gotten, have worked well, for awhile. Then they always slow down no matter how much I oil the rods or adjust the belt. The Chicago Electric tumblers seem to be the worst. Even my Lortones have slowed down considerably after awhile. I have read that for a 4” barrel it should turn between 50/ 65 rpm. The bigger the barrel the slower it should turn. After my modification my 3#ers run 55/60 rpm, and my 12# runs 30/35rpm now. This is what I do to all of my tumblers after I get them home. Here is a picture of the different pulleys from the tumblers, from left to right is the new pulley for the dual 6# and 12# Lortone. Then the stock pulley from the 6 and 12#, and the stock pulleys from the Lortone 3# and c.e. 3#   First I go to the hardware store and pick up a single eye pulley and use the dremel with a cut off disc, to cut the pinhead off. The wheel slips right out then. The eye on this size pulley fits the shaft on the 6, 12# Lortones just right. If the pulley you get doesn’t fit drill the eye out using a small bit working up bit by bit till you get a snug fit on the shaft. I don't worry about the fan blades on the stock pullies The motors don't seem to heat up to much from when they had the fans on them. If your motor heats up alittle more you can take the cover off of the smaller Lortones and cut vents or take the cover off completly.   Then I get the solder and butane torch and solder the pulley to the shaft in the front and back. Be sure the pulley is on straight before you solder or it will wobble once running. I have a pulley that wobbles slightly on one of my 3# Lortones, but it doesn’t wobble much to effect the belt at all. You will need to get a slightly bigger belt also. I took the measurements and went to a place called Fastenall; they are nation wide and sell all kinds of stuff for contractors, with a wide selection of rubber belts, or "o" rings. Here they are on the Lortone and c.e. tumblers.   |

|

|

|

Post by Jack ( Yorkshire) on Jan 25, 2006 7:53:10 GMT -5

Hi Earthdog

Brilliant Idea Thanks for sharing I like a guy that uses "other things" for pulleys

I use some plastic pram wheels (with the tyre removed ) as pullys on one of my tumblers

Jack

Yorkshire UK

|

|

stefan

Cave Dweller

Member since January 2005

Posts: 14,113

|

Post by stefan on Feb 3, 2006 13:43:22 GMT -5

thanks E- Hmmm Pullies a butane tourch- a cut off wheel---sounds like a fun evening to ME!!!!

|

|

earthdog

Cave Dweller  Don't eat yellow snow

Don't eat yellow snow

Member since June 2006

Posts: 2,731

|

Post by earthdog on Feb 3, 2006 22:17:32 GMT -5

I just switched the 1.5" pulleys on the 12 and dual 6# Lortone's to 2" pulleys and they zoom.

Both are running about 55/58 rpm's now.

|

|

|

|

Post by stoner on Feb 4, 2006 2:51:33 GMT -5

Hey Edog. Cool mods. Now that they are rolling faster, use a little less water and some 45-70 grit and you'll cut your roughing time by about 1/3. Try it, you'll like it.

Ed

|

|

earthdog

Cave Dweller  Don't eat yellow snow

Don't eat yellow snow

Member since June 2006

Posts: 2,731

|

Post by earthdog on Feb 4, 2006 9:21:51 GMT -5

I have been using 46/70 from the rock shed for about a year now. Before that I was using straight 80 grit. When the big barrels were rolling about 40rpm, I recharged every 3 days. I'll see now if it will be sooner.

|

|

drupe

fully equipped rock polisher

Member since September 2005

Posts: 1,245

|

Post by drupe on Feb 4, 2006 9:29:17 GMT -5

Thanks for the info Edog. I'm headed to Lowes on Monday.

Pete

|

|

|

|

Post by texasrockhound on Mar 7, 2006 10:13:02 GMT -5

EDog...Thanks for the info...I was able to use your fix on my 3# CE tumblers and am quite pleased with the result......those suckers are turning pretty quick now! And I don't have to worry about the old pulley chewing up the belts any more...Gonna change out the pulleys on my Lortones next..

Thanks again dog!

|

|

|

|

Post by texasrockhound on Mar 8, 2006 9:18:51 GMT -5

WOW! I have 2 - 3# barrels turning on a moded CE...1 in 60/90 and 1 in 120/220...I checked both barrels after just 3 days it looks like all of the grit has completely broken down...it was taking at least 7 days before...buying more pulleys today!

|

|

earthdog

Cave Dweller  Don't eat yellow snow

Don't eat yellow snow

Member since June 2006

Posts: 2,731

|

Post by earthdog on Mar 10, 2006 0:28:27 GMT -5

Hot damn, I'm glad I could help a couple people.

I first did the change on my CE tumbler and it worked great. Now whenever I get a new tumbler, thats the first thing I do.

|

|

SteveHolmes

fully equipped rock polisher

Member since July 2009

Posts: 1,900

|

Post by SteveHolmes on Mar 10, 2006 16:01:06 GMT -5

Thanks E-dog,

Just checked my Lortone 33B speed, and it['s turning about 35 RPM...guess I'll have to modify. Do I need to be at around 55-60 RPM? There's not a special tool to check RPM is there? I just marked the lid and counted how many times it went around in a minute.

Steve

|

|

earthdog

Cave Dweller  Don't eat yellow snow

Don't eat yellow snow

Member since June 2006

Posts: 2,731

|

Post by earthdog on Mar 11, 2006 11:29:21 GMT -5

Thats all I do Steve, mark the lid and count.

Quite a few websites I have read that for a 3# barrel 50/60 rpm, you get the best results. and faster results.

I always read that on the 6 and 12# barrels that they should spin slower, From what I have seen with my 3, 6# and 1, 12# the only bad thing is that if I have some real thin shapes, once in a while they may break, not all the time but once in a while.

It's to bad we can't rig one of those numbered counters on a tumbler to count for us, or a tachometer somehow.

You know what, I wonder if I could solder a tab on a lid, to click a counter everytime it makes 1 rev.

I'm gonna think about this now. those counters aren't to much. I could even rip one from work, we use them on our barrels for the cement mixers...

|

|

Rockygibraltar

fully equipped rock polisher

Member since February 2006

Posts: 1,404

|

Post by Rockygibraltar on Mar 11, 2006 23:48:09 GMT -5

Hey Earthdog have you gone through to polish with the faster rpm? I was just wondering about the effect on polishing.

|

|

earthdog

Cave Dweller  Don't eat yellow snow

Don't eat yellow snow

Member since June 2006

Posts: 2,731

|

Post by earthdog on Mar 12, 2006 21:59:34 GMT -5

It worked good for polish also. I always use plenty of pellets also. Another way to speed them up, is to wrap duck tape around the rollers, try to make sure its even on both rollers to. you can double the thickness of the rollers and they will go pretty fast.

|

|

|

|

Post by texasrockhound on Mar 13, 2006 12:50:24 GMT -5

Dog - finished modding the other CE and my 2 Lortones...all are spinning happily at about 60 rpms now....On the Lortones I had to use the existing pulleys....I just super-glued the new pulley right on the end of the existing pulley (can't solder the existing alluminum pulley) . Works great! I should post some pics....eh... maybe I'll get around to it...Spring is awefully busy for me....

|

|

earthdog

Cave Dweller  Don't eat yellow snow

Don't eat yellow snow

Member since June 2006

Posts: 2,731

|

Post by earthdog on Mar 13, 2006 14:27:27 GMT -5

Is the super glue holding good?

|

|

|

|

Post by texasrockhound on Mar 14, 2006 13:19:27 GMT -5

Yea, it seems to be holding up pretty well. I had to do it that way cause the Lortone drive shaft is so short and the pulley wouldn't line up...but the barrels are turning and that's all that matters. Man my tumbling times have shortened drastically!!

|

|

earthdog

Cave Dweller  Don't eat yellow snow

Don't eat yellow snow

Member since June 2006

Posts: 2,731

|

Post by earthdog on Mar 14, 2006 15:15:47 GMT -5

Yeah, thats what I'm talkin 'bout...

|

|

yogi

starting to spend too much on rocks

Member since March 2006

Posts: 175

|

Post by yogi on Mar 16, 2006 22:02:15 GMT -5

Very cool idea Earthdog. Do you think replacing the pulley will help with the CE's belt problem ( Ive went through the original plus 3 'O ring' belts since I got the tumbler 3 weeks ago).

Bill

|

|

yogi

starting to spend too much on rocks

Member since March 2006

Posts: 175

|

Post by yogi on Mar 16, 2006 22:03:25 GMT -5

JB weld epoxy will bond it too.

|

|