|

|

Post by akansan on Feb 23, 2008 22:26:52 GMT -5

Okay, it's my turn for saw problems. I switched out the blade on my saw today (thanks, JSGems!), and as I was making my first cut, I noticed the belt had some wobble in it. It looks like the shaft going into the motor is bent. I don't know if this is something I can tighten, or if I need to somehow straighten it, or if it's okay (for the time being) running the way it is. But with the wobble, the belt has periods of being stretched too tight and periods of being completely slack. This also (of course) affects blade speed. I think I found the culprit for the bent blade - one of the set collars had worked its way loose, creating slack on the arbor so the blade arm could bounce about 1/8" during a cut. This problem might have caused the crooked shaft as well, but I don't know. I tightened up the collar, but watched that first cut really closely, which is how I noticed the wobble. I didn't get pictures of it in action today, but I'll take a picture tomorrow. In case you're wondering what I'm talking about - here's pictures of my saw while it was still clean...  The offending area is circled in red. Is there something on a motor that I can unscrew or detach to straighten that shaft up, or do I just need a new 1/3 hp motor? |

|

|

|

Post by captbob on Feb 23, 2008 22:50:43 GMT -5

I'm NO expert  but is there a set screw on that pulley you can loosen and move the pulley in closer to the motor? Seems the further out on the shaft it is, the more strain... I'll wait here with ya for the cavalry ;D Please send 'em over if they get here first! ;D |

|

|

|

Post by catmandewe on Feb 24, 2008 1:22:52 GMT -5

If the shaft is bent it has to be straighted or it will wear out the bearing in the motor in a hurry.

Take the belt off the pulley and turn the motor on, it will be pretty easy to tell if it is bent or not.

If it is a slight bend you should be able to bend it back, but you will have to take the pulley off to do it right. The pulley needs to be aligned with the other pulley when you put it back on, to prevent premature wear on the belt.

Tony

|

|

|

|

Post by bobby1 on Feb 24, 2008 1:47:49 GMT -5

Also, check that the bore on the pulley isn't worn and allowing it to be off center.

Bob

|

|

|

|

Post by johnjsgems on Feb 24, 2008 8:22:55 GMT -5

Ronda, I can't tell by the picture but it looks like the motor needs to be alligned. Loosen the motor mounts and swivel it until the belt/pulleys are alligned. Also remove belt and see if shaft moves side to side (worn bearings). That could make it look like it is bent.

|

|

yogibear

starting to spend too much on rocks

Member since December 2006

Posts: 100

|

Post by yogibear on Feb 24, 2008 10:14:17 GMT -5

If you look at the length of the adjustment slots showing then Johnjsgems is correct. The motor is sitting sidewise and could be the reason for the problems you are having.

Bill

|

|

|

|

Post by akansan on Feb 24, 2008 16:18:27 GMT -5

I guess I should have specified - the above picture was of the saw before it came to me. My best guess it was the seller's pictures who sold it to the guy who then sold it to me. It wasn't that clean when I purchased it, that's for sure! The motor definitely needs aligned.  Also, there appears to be a loose piece on the motor and I'm not really sure how long it's been loose. I noticed it during this cut, but I admit - I haven't paid attention to it before:  It's the silver cup that's at an angle in this picture. It fits against the motor on the right side. Is it important? There doesn't appear to be any wear in the pulley bore or the shaft bearing. There's no play in them. I'm going to try the "remove pulley and turn on motor" test to see if it's crooked or not. I notice the "wobble" when I turn the belt. I suppose the pulley could be set unevenly? I have to take the saw apart anyway to clean out the pan. The drain pipe appears to be clogged with a shard or something (from what my very dirty fingers could feel yesterday...ewwww), and rather than remove the pipe and pour sludge all over my shop floor, I'll have to do it the old-fashion way and remove the saw from the pan and pour it all into a drain bucket. |

|

|

|

Post by catmandewe on Feb 24, 2008 16:40:31 GMT -5

Ewwww, that looks like the race for your bearing.

Looks like you have a motor shaft bearing that came apart, which could easily give the appearance of a bent shaft. Hopefully you can just replace the bearing. Not too terribly hard, if you can find one the right size.

Tony

|

|

|

|

Post by akansan on Feb 24, 2008 17:21:26 GMT -5

LOL - I guess that means that part is important. All right - I'm going to go out and remove the pulley and see about taking apart the motor. I wasn't looking forward to getting greasy again today.  |

|

|

|

Post by rocklicker on Feb 24, 2008 17:25:35 GMT -5

Hmm, if it helps, I can take a photo of my saw. It looks exactly the same. The motor on it appears to be the original one and was never adjusted, so that may not help.

Steve

|

|

|

|

Post by akansan on Feb 24, 2008 17:43:35 GMT -5

Okay, removing the pulley is going to take something special. The allen wrench doesn't budge it, and neither does my drill (with the appropriate bit inserted) which worries me. I removed the pulley on the other side to get the belt off, and there's definitely a wobble on the shaft when spinning.

That's as far as I can get until I get something besides WD-40 to unstick that set screw. Additionally, I'm not certain how the other half of the pulley is attached to the shaft - all the set screws are missing from that half. So I have one half with a set screw that doesn't want to budge, one half that is stuck to the shaft magically, a bent shaft, and a bearing that appears to be falling apart.

That about sum it up?

Where would I find a bearing the correct size? the shaft is either 5/8" or 1/2". I can't tell until I get that stupid pulley off!

|

|

|

|

Post by akansan on Feb 24, 2008 17:47:55 GMT -5

Rocklicker - you have a 14" drop saw as well? Does yours have the belt guard and the splash guard attached? I've been looking for photos of those pieces so I can get something fabricated to do the same work, but I haven't been able to find any!

But yeah - any pictures of the motor end of your saw would definitely be helpful. I've only had this one for a few months. I just received the owner's manual from Lortone, but it doesn't help me much...

|

|

|

|

Post by rocklicker on Feb 24, 2008 18:14:17 GMT -5

Yes, it's a 14 inch drop saw. It's a different color, but I imagine the vary same one. There does appear to be a splash guard but no belt guard. Here's a shot of the motor and the pulley. It's hard to see given the space between the motos and the pulley, but that bearing race is not there. So is the motor shaft that wobbles or the saw shaft? If it's just the race that came out, you may be able to just repack the bearings and stick it back in. You would have to pick up some bearings (the little balls). It may be just as easy to replace the bearing provided you can find one. OK, here's the same shots you have in this post of my saw. I'll get some of the splash guard too. Steve   |

|

|

|

Post by captbob on Feb 24, 2008 19:03:55 GMT -5

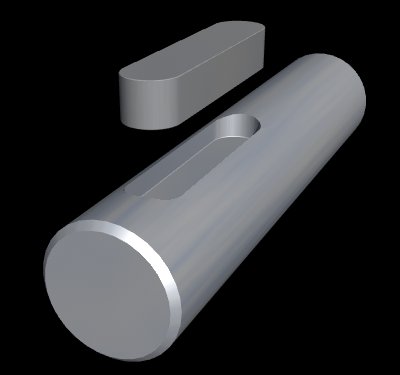

Many, maybe most, pulleys have keys in the shaft holding the pulley from being able to spin. Try a little W-D on the pulley and let it sit overnight. You may have to actually tap the pulley the wrong way a bit to get to the key before you can take the pulley off. The key is just a metal wedge (?) in the shaft that the pulley is on. I'll go see if I can find a picture example and post it. okay, here would be your pulley  and this is the shaft & key  now that you know what's under there, maybe it will be easier to remove. |

|

|

|

Post by akansan on Feb 24, 2008 19:10:37 GMT -5

Hmm - looking at your motor end pulley, I'd say mine's been replaced and you have and original. That might be when the belt guard disappeared on mine.

I can see where the race goes. I'll work on getting the pulley off and see if I can reattach the race.

How do you repack a bearing?

|

|

|

|

Post by captbob on Feb 24, 2008 19:14:08 GMT -5

What kind of bearing? Some you don't. You can repack a roller or needle bearing (like on a car), but probably not the type of bearing in a motor that small. That's most likely a sealed bearing.

|

|

|

|

Post by akansan on Feb 24, 2008 19:18:23 GMT -5

Captbob - yeah, I know what you're talking about. But I can't turn the set screw in the pulley. It won't budge. I tried it with my drill even, and my drill won't budge it either. I gave it a couple blasts of WD-40, so I'll see if that helps it out over night. In fact, I can move the pulley slightly on the shaft (learned by hitting the allen wrench with another wrench I had handy  ) but I can't loosen up that set screw. I tried both righty-tighty and lefty-loosy just in case it was one of those stupid left-hand threaded things.  |

|

|

|

Post by akansan on Feb 24, 2008 19:20:51 GMT -5

It's a ball-bearing motor, so I'm assuming that means the bearing on the shaft is a ball bearing and not that something in the motor itself requires ball bearings. Right?

So, if I can't replace the bearing, then am I looking at a new motor?

|

|

|

|

Post by captbob on Feb 24, 2008 19:38:40 GMT -5

You sure that's not just a dust cap that's off in the 2nd pic on post 6? What can you see inside that?

never buy a new motor! you can probably get one for a song at a 2nd hand appliance shop. I wouldn't think of paying more than 10 bucks for a motor, which is why it's easier to replace than fix them sometimes.

I don't know how big your town is, but I bet there's a junk shop/yard.

If you have a favorite auto mechanic, he probably has a gear puller that would get that pulley off if needbe.

|

|

|

|

Post by captbob on Feb 24, 2008 19:53:12 GMT -5

I would think (which my wife says I'm not allowed to do) that your motor has sealed bearings like this  but, you may have ball bearings like this  you can repack a ball bearing, although it could be the center hole is your problem or your shaft is bent, and not that the bearing needs repacking. If you get to needing to repack them it's easy and we can worry about that when the time comes. You would need something to clean out the bearing with (gas works) and some grease. |

|