|

|

Post by 150FromFundy on Feb 5, 2010 18:50:35 GMT -5

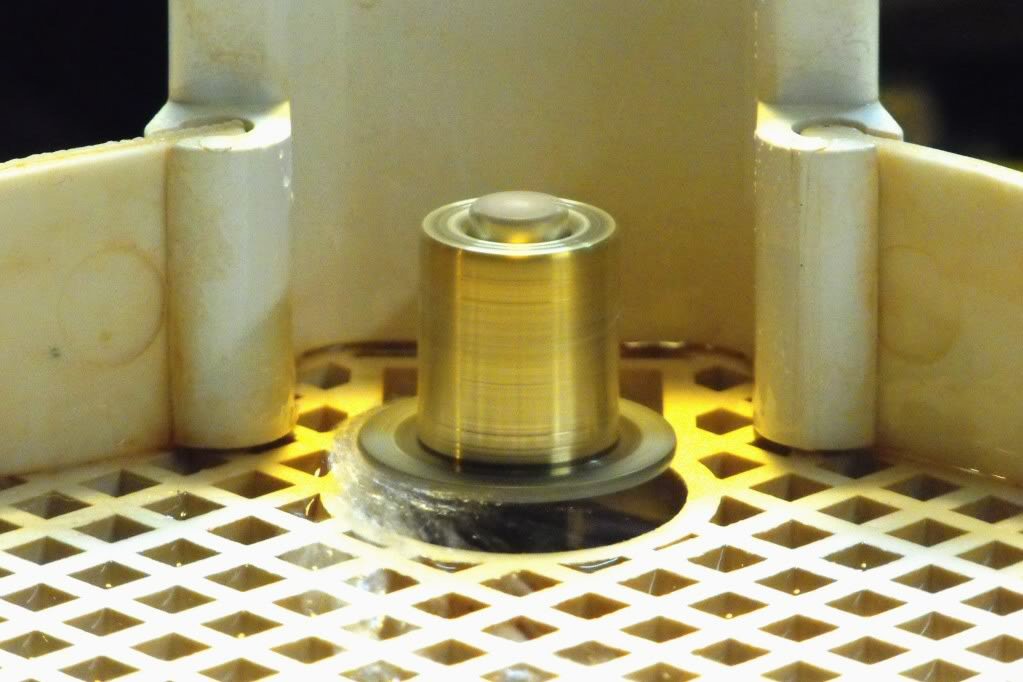

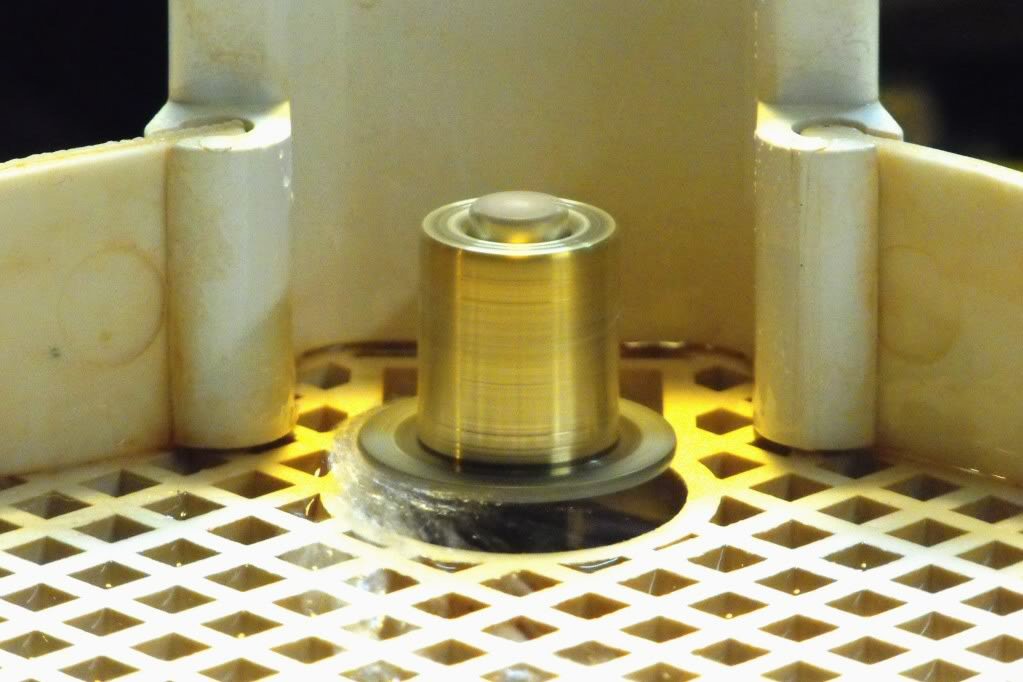

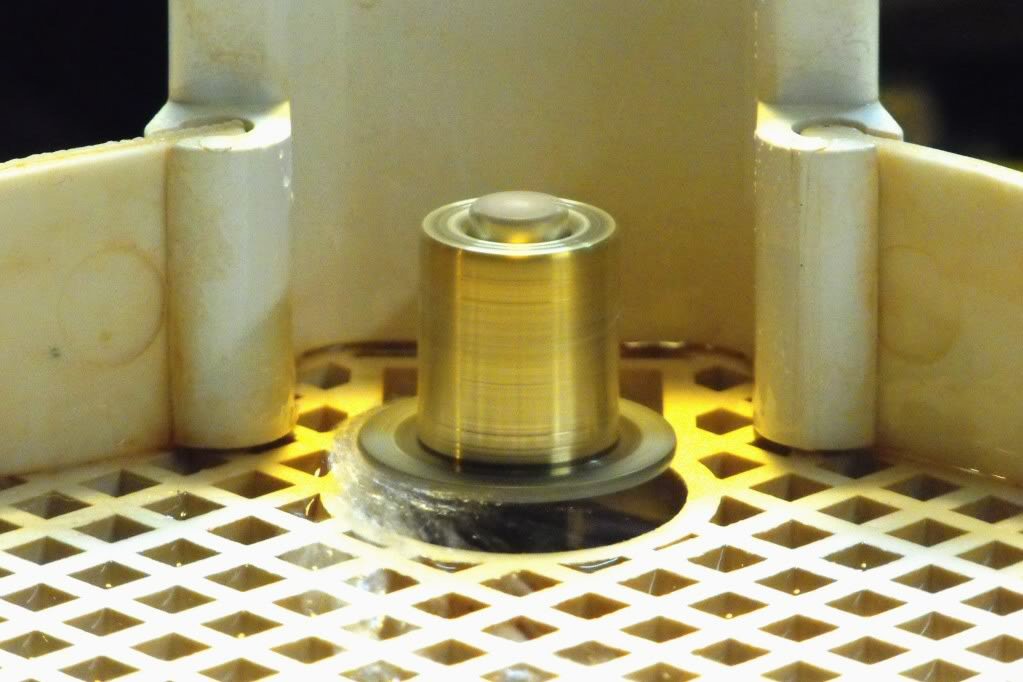

I finally changed my grinding bit to a groove bit and decided to post a few pictures of my first attempts. I’ve recently posted How to Drill a Pendant, and this hopefully will be a good follow-up on another way you can finish your preforms into pendants. For this, you will need a Gryphon Grinder or equivalent. This is the Groove Grinder from Gryphon Corporation. It retails for $13.95. I have no idea how long it will last. Grooves are cut in polished preforms. The wire will fit into the groove and cover any visible areas that have been roughed up.  You need to make a little height adjustment of the Groove Grinder on the arbour. If your preforms are not perfectly uniform in thickness (like mine), centre the Groove Grinder on the thinnest part of the preform. If your preforms are perfectly uniform in thickness, simply centre the Groove Grinder.  Start up the spin cycle. Ooooh, look at all that water! The pump is available only on the Gryphon Twister. The previous two models use a drippy sponge. This is a really nice feature!  When grinding the groove, apply minimal pressure. Rotate the preform around the Groove Grinder making a very shallow cut with each rotation around the bit. It should take several rotations around the bit to cut the groove deep enough for the wire to be flush. Have a piece of your wire handy to check the depth of the groove periodically. It should take 2 to 3 minutes of grinding and checking to finish the groove. Here are my first six attempts. Two Rose Quartz, two Lavender Blush, one Smokey Grey and one Banded.  From what I can tell (and I am completely new at this) the art is in getting the depth of the groove perfectly uniform all the way around the preform. If the groove is too shallow, your wire will project. If your groove is too deep, your wire will be buried.   This is where I recognize and salute the talents of Adrian who has created a comprehensive post on how to wire up the groove wrap. forum.rocktumblinghobby.com/index.cgi?board=wwp&action=display&thread=30091I will be reading Adrian’s post myself this weekend in an effort to finish these off. But for now, it’s time to get back to the grind (groove grind that is). Darryl. |

|

snuffy

Cave Dweller

Member since May 2009

Posts: 4,319

|

Post by snuffy on Feb 5, 2010 19:01:48 GMT -5

Hey,Darryl, looking good. How thick are your cabs? If I got one of those I would have to make my slabs thicker. It sure is relaxing sitting and playing on the gryphon.Did you wear out a bit yet?

snuffy

|

|

NorthShore-Rocks

fully equipped rock polisher

Member since December 2008

Posts: 1,004

|

Post by NorthShore-Rocks on Feb 5, 2010 22:43:52 GMT -5

Another great looking "how to" Darryl! Thanks!

|

|

Mudshark

fully equipped rock polisher

Diplomacy is the art of saying 'Nice doggie' until you can find a rock. Will Rogers

Diplomacy is the art of saying 'Nice doggie' until you can find a rock. Will Rogers

Member since December 2008

Posts: 1,083

|

Post by Mudshark on Feb 6, 2010 17:12:15 GMT -5

Great post Darryl.I have the same setup and like you say getting the groove depth just right is tricky.I just about slabbed the first one I did.I've been thinking of making some sort of depth-stop but haven't had the time to try anything out yet.Maybe someone here knows of something available.

I'm still practicing with copper but I just got a 1mm bit from Inland for when I'm ready to start with Sterling.Adrians post is is really helpful for anyone wanting to try this.

Mike

|

|

|

|

Post by sandsman1 on Feb 7, 2010 3:14:31 GMT -5

that machine is too cool -- you make it look easy with that new bit haha

i thought about trying one of my drill presses i have one for a reg drill and one for the dremel but id have to use a wizzer wheel i think -- i dont know if that will even work

|

|

|

|

Post by frane on Feb 8, 2010 20:16:54 GMT -5

Looks like you did pretty darn good the first time trying that gryphon! I think someone mentioned using washers to hold the grove maker at the right place. I am just not sure exactly how they did that.

Fran

|

|

catskillrocks

fully equipped rock polisher

Member since July 2008

Posts: 1,270

|

Post by catskillrocks on Feb 8, 2010 21:20:31 GMT -5

Thanks for the groove progression Daryl. As far as trying

to figure out how to keep the groove depth even, I'm

pretty sure that Tony (tonyturner) was going to try & get

a setup that would do that. Not sure if he ever did, but

there was a post quite awhile ago from Amber (bejewelme)

that he was going to try & tackle it. Hope he sees this post

& lets us know!

Don

|

|

|

|

Post by llana2go on Feb 11, 2010 9:27:07 GMT -5

Another great tutorial! Thanks.

I have been thinking about getting one of those Gryphons. Figure if I can't wire wrap, I can maybe groove wrap. Besides, it just looks like it would be fun to play around with and see what all ya' could use it for.

|

|

|

|

Post by MyNewHobby on Feb 11, 2010 16:55:27 GMT -5

Great grooves!!

Seeing this post has made me want to pull out my Gryphon and start up again. A much needed kick in the butt.

As always

Julie

|

|

|

|

Post by Bejewelme on Feb 17, 2010 13:03:05 GMT -5

if you look at the diamond bit we try to make the depth equal to that, sort of a guide, Tony has not come up with any other way of getting it even, they never are, but the good thing if too shallow you can go and re-cut, if too deep well then cut it deeper all around, LOL. It is the best little machine ever, I really need to use it again to shape my cabs, my cabs have been looking bad shape wise and it is much easier to shape them with this. It was such a pleasure meeting JohnJSGems in Tuscon, he offeres us a great deal on these machines.

|

|

|

|

Post by rocklicker on Mar 28, 2010 2:24:21 GMT -5

Cool setup! I think it's time for me to get into the groove soon... add that to my large list of things to do ;D

Steve

|

|

cman

starting to spend too much on rocks

Member since August 2009

Posts: 207

|

Post by cman on Jul 5, 2010 19:08:06 GMT -5

I tried out the grover the other night love it. Lots of power with the basic Gryphette Grinder.

Happy I bought it on sale at Delphi.

Cliff

|

|

|

|

Post by Roller on Jul 5, 2010 22:10:27 GMT -5

interesting!!! The only way I can figure out having the exact desired cut would be if the cab was a circle and made stationary ..maybe a sliding stop plate installed ...or something else to stop you from going further ... ... Otherwise there would need to be some sort of guide in the floor of the unit that guided an exactly sized cab for that purpose which poses a problem ... I enjoyed your first thread and am interested in seeing how this one plays out !!!

|

|

chromenut

fully equipped rock polisher

Member since December 2009

Posts: 1,971

|

Post by chromenut on Aug 16, 2010 10:32:34 GMT -5

Question - will the groove grinder bit fit the Gryphette grinder?

|

|

|

|

Post by jakesrocks on Aug 16, 2010 10:55:39 GMT -5

For those wanting to try this in a drill press, there is a diamond edged blade used in the fiberglass industry for trimming molded parts. It fits a 1/4" mandrel, which fits in the drill press. These blades are about 2-1/2" in diameter, and about 1/16" thick. I'll dig one out of my tool box and post a pic of it and the mandrel later. A person would probably have to make a cover for thrie drill table out of about 1/4" plexiglass, to prevent their cab from slipping into one of the larger holes in the drill press table. The blade would be lowered to the desired position, and locked at that hight. Since the motor would be above your work, a water feed could be used to cool the blade.

Don

|

|

|

|

Post by johnjsgems on Aug 17, 2010 0:21:01 GMT -5

As far as I can tell all glass grinders use a 5/16" shaft so everybody's bits work. The exception was the Ameritool "router adapter". Their shaft is 3/8" but they discontinued it a while back anyway.

|

|

|

|

Post by jakesrocks on Aug 18, 2010 14:45:02 GMT -5

Here are the diamond blades I spoke of. The sizes I have are 1-3/4" and 2" dia., and fit a 1/4" mandrel. They are made by NASSCO Tools -- www.nassco.net/-- I believe these could be used in a drill press for grooving cabs.  I would suggest breaking these blades in on a piece of scrap agate before attempting to try grooving, as the diamond grit is quite course. Don |

|

|

|

Post by frane on Nov 14, 2010 18:40:39 GMT -5

I have one of those that will work on the Inland flat lap too. I just have not tried it yet but seeing this post has convinced me to find it and try it out.

Fran

|

|

rockwizz

freely admits to licking rocks

Member since May 2007

Posts: 971

|

Post by rockwizz on Mar 25, 2011 15:12:40 GMT -5

nice...are you using a dremel underneath?

|

|

electricmonk

spending too much on rocks

Member since August 2011

Posts: 281

|

Post by electricmonk on Oct 1, 2011 18:48:15 GMT -5

I wonder if you could set groove depth the same way they do with wood router bits. Typically a ball bearing is placed inline with the bit, the bearing surface prevents the work from going deeper than the bearing diameter which acts as a positive stop. I wonder if some sort of sleeve could be placed around the shaft which would do the same?

|

|