sampson

starting to spend too much on rocks

Member since April 2011

Posts: 222

|

Post by sampson on Dec 12, 2011 19:09:52 GMT -5

Looks good Justin, can't wait to see some finished spheres come of it. I went into town again today and my motors still haven't come in. Guess i'll just check back later in the week again. If i had to guess about your nodule jumping out i would say two things. First is that it appears pretty rough on the outside which may make it jump out, grinding it somewhat smoother may help. The second thing i notice is the two grooves or notches in your grinding cups/core bits. I guess since they are made for drilling that those notches would help clear the cut but for your application i think they may catch on any protrusion off your preform and eject it. Maybe try tounding the corners of the notches a little so that it doesn't catch as easy? Hope you get it working, can't wait to see some finished product.  |

|

|

|

Post by jakesrocks on Dec 12, 2011 19:36:11 GMT -5

Hey Justin, another thing you might try is less angle on your cutters at the start. As material is removed, the cups will angle down on their own.

|

|

|

|

Post by jakesrocks on Dec 13, 2011 14:45:16 GMT -5

Here's an interesting link for you sphere cutters, and soon to be sphere cutters. www.dragonspheres.com/This is the company that I ordered my cup adapters from. Don |

|

|

|

Post by jakesrocks on Dec 13, 2011 18:41:30 GMT -5

Yaaa Hoooo !!! My cutter adapters came in today. They're made from 1-1/16" cold rolled steel. real heavy duty. If the motors will handle the load, they'd have no problem handling cutters for a 6" sphere.

|

|

juzwuz

has rocks in the head

Member since April 2010

Posts: 526

|

Post by juzwuz on Dec 14, 2011 0:42:59 GMT -5

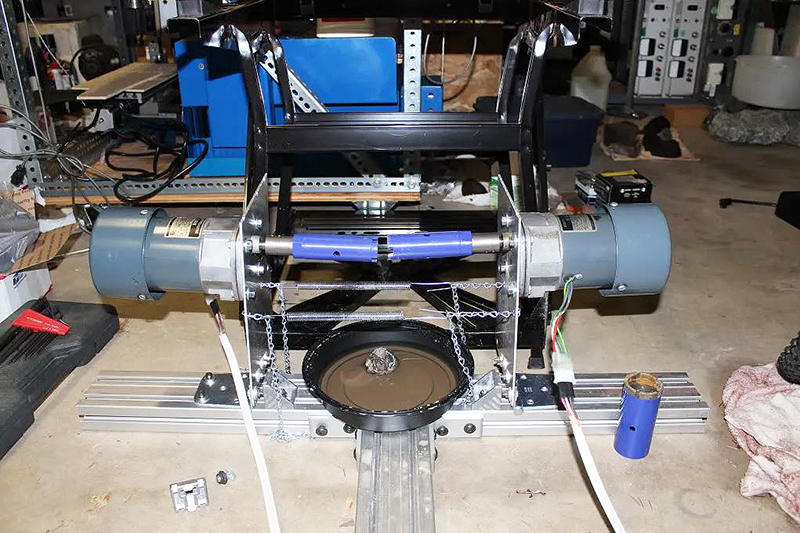

Thanks for the link Don. The indexing clamp thing looks pretty interesting. Sampson - I'm coming to the conclusion that the geode/nodules I'm using need some grinding. I guess I have to revive my cabbing unit project which has been on hold for several months now. Here's some updated pictures of the 2-head configuration and 3-head configuration. I tried the 3-head configuration but the springs were too long. I picked up some shorter stronger springs today but haven't attached them yet.   |

|

|

|

Post by jakesrocks on Dec 14, 2011 10:17:33 GMT -5

Hey Justin, on that link, did you check out their cutters ? Not a bad price on the complete sets.

|

|

|

|

Post by jakesrocks on Dec 14, 2011 11:59:41 GMT -5

In the beginning there were parts. Lots of parts. Jake thinks there might be food in there too.  The T-slot rails have been drilled, counter bored for screw head clearance, and countersunk so the T-nuts will pass over the mounting screws. Aircraft grade machine screws and self locking nuts being used where possible. |

|

|

|

Post by Donnie's Rocky Treasures on Dec 14, 2011 18:34:59 GMT -5

All right, then, looks like you're moving right along!

|

|

sampson

starting to spend too much on rocks

Member since April 2011

Posts: 222

|

Post by sampson on Dec 14, 2011 18:36:58 GMT -5

Wow, you are just way too organized there. Looks like you have lots of help though, those three pudgy cold guys in the background to do all the work and the hound to supervise it all.  |

|

|

|

Post by jakesrocks on Dec 14, 2011 22:26:44 GMT -5

Sampson, it may look organized in the pic. If I had turned 90 deg. to the right, you would have seen about 10 opened FRB's of rocks that need to be hauled to the basement.

Tomorrow I get the base board drilled, cut, routed, sanded and at least 2 prime coats on it.

|

|

|

|

Post by jakesrocks on Dec 15, 2011 11:22:29 GMT -5

Found a link to a bunch of short videos last night about sphere cutting. These are a bit difficult to view. Best to nurse each one through the first viewing, and then run them through a second time. These were made using a 3 head machine, but the same should apply to 2 head machines. www.dragonspheres.com/misc.htmAs soon as the honey do list is complete, I'll get started on the base for my new toy. Hope to post a pic tomorrow. Don |

|

|

|

Post by jakesrocks on Dec 17, 2011 22:37:24 GMT -5

Lesson learned. Never lay out parts when you have the flu. Fired up the band saw this afternoon, and was ready to start cutting the base board. Something didn't look right, so I re- measured everything before cutting. My angles were wrong. So I just spent the last 2 hours laying out my cutting pattern on the opposite side of the board. Checked the layout on my motor mounts, and they were marked wrong too. Guess I'll try again tomorrow.

|

|

WarrenA

fully equipped rock polisher

Member since November 2003

Posts: 1,530

|

Post by WarrenA on Dec 18, 2011 0:26:15 GMT -5

good thing you checked when you did

|

|

|

|

Post by jakesrocks on Dec 18, 2011 11:40:14 GMT -5

We'll give this another try this afternoon. Got everything layed out right now. I was looking for the correct colors of wire to keep everything color coded that I could buy by the foot. Found it at O'Reilly Auto Parts in all of the right colors. Only $.19 per foot. They also have flexible wire conduit to protect the wires at $4.99 for a 10' role. I like that you can print a shopping list right from their online catalog, and print it out complete with barcodes. Just take the list to them. They scan it, and get just what you need. www.oreillyauto.com/site/c/home.oapDon |

|

sdgoldpanner

starting to spend too much on rocks

Member since January 2006

Posts: 226

|

Post by sdgoldpanner on Dec 18, 2011 13:57:05 GMT -5

|

|

|

|

Post by jakesrocks on Dec 18, 2011 14:26:44 GMT -5

Hey Bob, glad to see you on here. Don't be such a stranger. You been cutting any spheres lately ?

Why don't you post pics of your home built machine on here ?

Don

|

|

sampson

starting to spend too much on rocks

Member since April 2011

Posts: 222

|

Post by sampson on Dec 18, 2011 15:31:01 GMT -5

I have looked at the diamond rods too and think they would work great in this application, thanks for your first hand experienced input. I am also using the pipe fitting reducing couplers but had planned on mixing tumbler grit to make a paste and do the small chain over one cup thing i saw in a video. If that works too slow or i get real serious about making spheres i will take a more serious look at the diamond rods to speed things up.

I wish i could start building my machine but i checked the mail on friday and still no motors. Tomorrow, (monday) will be a full three weeks since i placed my roder so i sure hope they get here soon so i can get building.

|

|

sdgoldpanner

starting to spend too much on rocks

Member since January 2006

Posts: 226

|

Post by sdgoldpanner on Dec 18, 2011 15:48:04 GMT -5

Hey Bob, glad to see you on here. Don't be such a stranger. You been cutting any spheres lately ? Why don't you post pics of your home built machine on here ? Don Don, I have tried 2 different photo uploads and just can't get them to work. va rockhounder & the one mentioned here, pro board I think. Bob |

|

|

|

Post by jakesrocks on Dec 18, 2011 16:09:58 GMT -5

I'm going to try that chain over the cup thing too. It seemed to work real good in that video. I save my tumbler mud in a bucket, and let the water evaporate. A little chunk of that mixed with water and 60/90 grit should be thick enough for the chain to carry. It should supply enough water too.

Hey Bob, do you have a photobucket account ? That seems best for adding pics to this forum. Maybe you can post some of those beautiful Fairburns and make the folks drool.

Don

|

|

sdgoldpanner

starting to spend too much on rocks

Member since January 2006

Posts: 226

|

Post by sdgoldpanner on Dec 18, 2011 17:05:52 GMT -5

OK Don here is a try.  |

|