|

|

Post by NM Stone Supply on Apr 14, 2013 18:00:50 GMT -5

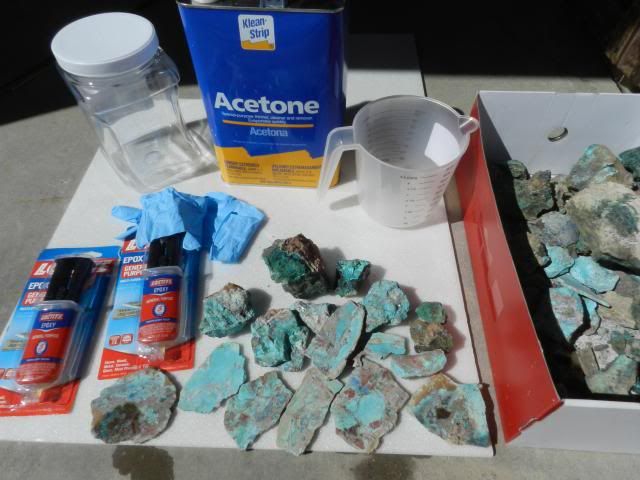

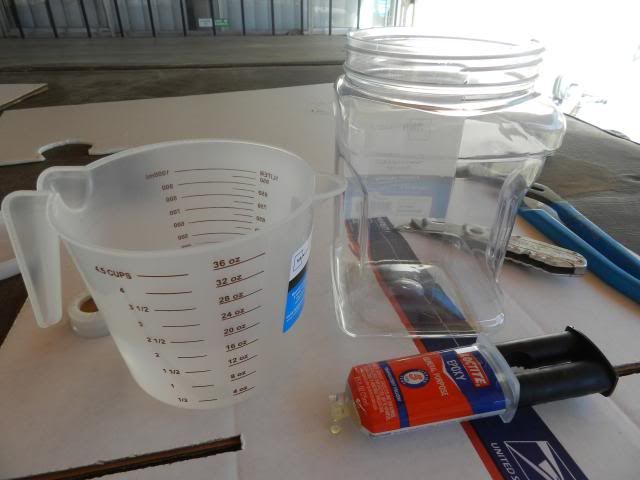

I have read many instructions on stabilizing turquoise. I am going to attempt this method on some chrysocolla that is somewhat too soft for me. Here is what I will use.  16 ounces acetone per tube of epoxy    Stir it up good then add the stones.  I used 3 batches to fill this little tub up with the mix. You can see it bubbling a lot as the mix soaks in.  I will leave it in here for 7 days then remove the stones and dry them for 7 days. I hope it works good. Jason |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Apr 14, 2013 18:22:20 GMT -5

Definitely keep us updated, I have been pondering what is the best/safest method for a while.

Thanks,

Tim

|

|

deedolce

fully equipped rock polisher

Member since October 2006

Posts: 1,828

|

Post by deedolce on Apr 14, 2013 19:11:21 GMT -5

Yes, I'd very much to hear the results. Love the photo 'how to' so far!

~D

|

|

|

|

Post by beefjello on Apr 15, 2013 8:20:21 GMT -5

I hope it works too Jason. Looking forward to seeing the results.

|

|

blackout5783

starting to spend too much on rocks

Member since November 2011

Posts: 248

|

Post by blackout5783 on Apr 15, 2013 8:35:50 GMT -5

Just a quick heads up and you might already know this, but if that's a plastic jar you have the acetone mix in keep a very close eye on it. Acetone can dissolve many plastics and you might check on it one day and just find a puddle of cured resin on the floor!

|

|

|

|

Post by phil on Apr 15, 2013 10:02:21 GMT -5

Tried that once on some turquoise. Kinda worked but took many weeks to soak in. And then only soaked in to the outer 1/8th inch or so.The only difference is I dried the stones in the NM sun for about 2 weeks (no rain) before I put them in there and pulled a vacuum on it after the stones were put in. Used both tubes of some 303 epoxy and about a gallon of acetone in an empty metal paint can (new). Left set in the NM sun as my heat source and mixed it up about every 2 days for the first 2 weeks. After about 2 months the liquid had turned to a semi-hardened jelly that easily came off the stones. Polished up OK, but I could tell the solution never made it to the center of the small stones I was using when I cut them in half to cab them. Only did it once, so no telling if it was a fluke or good idea.

Hope this helps.

|

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Apr 15, 2013 12:30:09 GMT -5

The professional stabilizers first pull vacuum to suck out the air. Then they put the entire mess under 4000psi to push the solution into the substrate. They use a heat cured acrylic.

Good luck Jason!!

|

|

|

|

Post by tntmom on Apr 15, 2013 14:07:18 GMT -5

I've tried this method before and like Phil, I only got it to penetrate 1/8". I have had more success heating the stones up and using Hxtal (Michael's method), reapplying to the surface a few times during 4 or 5 hours, sometimes it will wick through the stone completely if I keep it hot enough. I check it every hour or so and reapply when it has soaked in. I then remove it from the heat and let it cure for a week. (Hxtal is a water proof, UV proof, non yellowing, glass repair two part epoxy) www.hxtal.com/ |

|

|

|

Post by NM Stone Supply on Apr 18, 2013 7:06:10 GMT -5

Thanks for all the helpful tips. This is sure new to me. So far it looks good, they are still bubbling meaning the air is slowly coming out of the stone. I might leave this in for a couple weeks.

|

|

|

|

Post by deb193redux on Apr 18, 2013 7:31:17 GMT -5

excellent thread. I have been planning something like this for a long time, but I never get organized.

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,608

|

Post by jamesp on Apr 18, 2013 8:12:32 GMT -5

A food vacumn bagger dohicky machine is really great for this type application.A little vacumn goes a long way.And it is thrifty on the epoxy.And it can be set out in the sun immediatly after drawing a vacumn. PHD ReDnEck EnGiNeEr

|

|

keystonecops

freely admits to licking rocks

Member since October 2010

Posts: 957

|

Post by keystonecops on Apr 18, 2013 9:25:03 GMT -5

A food vacumn bagger dohicky machine is really great for this type application.A little vacumn goes a long way.And it is thrifty on the epoxy.And it can be set out in the sun immediatly after drawing a vacumn. PHD ReDnEck EnGiNeEr Thats a purty good title James  Later Clyde |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,608

|

Post by jamesp on Apr 18, 2013 10:03:55 GMT -5

I do my best to live up to it.I have 2 friends that come to my place to deer hunt and they are totally disfunctional and drink too much and trip over each other and everything is a big dramatic complicated problem.Dear wife and i crack up watching them.She named them KEYSTONECOPS.So you too have a purty good title.

|

|

|

|

Post by rockjunquie on Apr 18, 2013 13:00:47 GMT -5

Great and interesting thread. ;D I just want to give you a heads up. My brother in law came up with a way to vacuum seal mason jars with a brake bleeder. Works great, I do it all the time. www.instructables.com/id/The-Alvin-Vacuum-Sealer/I'm going to try this when I attempt some stabilizing. I have some chrysocolla that I'd like to make a little more user friendly.  Of course, I will be limited to the size of a quart mason jar, but my pieces are small. |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on May 15, 2013 21:09:20 GMT -5

Hey Jason,

How is it looking so far? I could not wait for your results and started my own batch. :-)

I HOPE it works.

Tim

|

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on May 16, 2013 10:50:07 GMT -5

I'll use Telas method with CA to see how it goes. I may use proper pump, dunno.

Cherdarock do you have a proper vacuum pump?

|

|

|

|

Post by FrogAndBearCreations on May 16, 2013 16:55:49 GMT -5

the only problem I see is that your mixing the hardener along with the resin in the acetone - that is not how I do it - I mix only the resin in the acetone for the saturation and then after several days sitting in a vacuum I hit it with the activator/hardener and put them under a 60watt light to cure for several days

|

|

mrribbit

off to a rocking start

Member since March 2016

Posts: 1

|

Post by mrribbit on Mar 24, 2016 21:12:30 GMT -5

so what was the end result I am gonna do it

|

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Mar 24, 2016 21:25:32 GMT -5

the only problem I see is that your mixing the hardener along with the resin in the acetone - that is not how I do it - I mix only the resin in the acetone for the saturation and then after several days sitting in a vacuum I hit it with the activator/hardener and put them under a 60watt light to cure for several days It wont hardn until the solvent flashes off. Two parts in solvent is ok, normal and customery for epoxy stuff... |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,608

|

Post by jamesp on Apr 1, 2016 8:16:34 GMT -5

Rocks being vacuumed using a food vacuum sealer. In this case vaseline. Vacuumed rocks in package placed in oven at 200F initially to reduce viscosity. Easy way to apply fairly good vacuum and safely heat at same time. Beware of acetone and it's flash point...  |

|