Post by 1dave on Feb 6, 2014 15:16:02 GMT -5

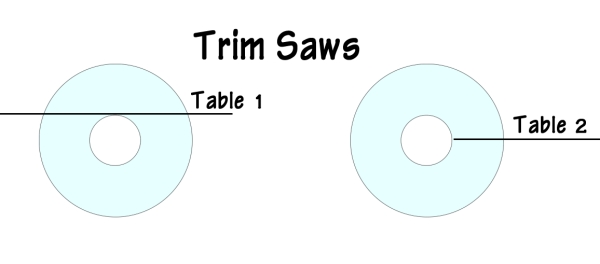

You have two choices when it comes to trim saws.

1. Saws with the table above the blade collar. This allows cutting longer stones

2. Saws with the table centered on the blade. This limits the length of the cut, but allows you to cut squarely into a pattern.

Type 1 saws are abundant varying from 4" to 12" blades.

[img src=" " alt="TS-1"]

" alt="TS-1"]

The Hillquist SF-8 Trim Saw is typical of this design.

www.hillquist.com/TrimSaw.htm

There are a lot more Tile Saws manufactured so you can usually get good buys on them.

IF all you plan on doing is trimming slabs, a small tile saw may be just the ticket!

Bigger trim saws can also substitute as a small slab saw.

Type two is presently a problem. It first came on the market as the Roth trim saw, and was taken over by Gemlap in 1958.

I believe they stopped manufacturing in the 70's, and I don't know of anyone who has taken up the design.

You could build your own, or make a tilted ramp so your slab came in on the proper angle.

I dug out the add I purchased mine from in 1960

It set me back $29.95! That was more than a weeks wages.

I built a shield for my saw. I should have made it 1/2 the size. Heating and bending the plexiglass would have been much easier. A better blade guard would have helped.

Use oil or water with your trimsaw?

Most trim cutting has to be hand held.

Water is far less messy and dangerous to your heath than oil. Use a little WD-40 to prevent rusting.

I built a plexiglass shield for mine, but heating it in hot water and bending it was hard.

I suggest making it half the size I did.

Post by Dave » August 25th, 2013, 8:47 am

Trimsaw thought

When cutting a slab on the trim saw, try turning the trim saw around so that you stand behind the saw and pull the slab toward you.

This eliminates most of the oil or water splattered all over you that you get if you try to push the slab toward the saw from in front.

You can also see what you are doing better when your glasses are not all oil splattered.

from NFMS Newsletter

Via Northside Gem and Hobby News 11/02

1. Saws with the table above the blade collar. This allows cutting longer stones

2. Saws with the table centered on the blade. This limits the length of the cut, but allows you to cut squarely into a pattern.

Type 1 saws are abundant varying from 4" to 12" blades.

[img src="

The Hillquist SF-8 Trim Saw is typical of this design.

www.hillquist.com/TrimSaw.htm

There are a lot more Tile Saws manufactured so you can usually get good buys on them.

IF all you plan on doing is trimming slabs, a small tile saw may be just the ticket!

Bigger trim saws can also substitute as a small slab saw.

Type two is presently a problem. It first came on the market as the Roth trim saw, and was taken over by Gemlap in 1958.

I believe they stopped manufacturing in the 70's, and I don't know of anyone who has taken up the design.

You could build your own, or make a tilted ramp so your slab came in on the proper angle.

I dug out the add I purchased mine from in 1960

It set me back $29.95! That was more than a weeks wages.

I built a shield for my saw. I should have made it 1/2 the size. Heating and bending the plexiglass would have been much easier. A better blade guard would have helped.

Use oil or water with your trimsaw?

Most trim cutting has to be hand held.

Water is far less messy and dangerous to your heath than oil. Use a little WD-40 to prevent rusting.

I built a plexiglass shield for mine, but heating it in hot water and bending it was hard.

I suggest making it half the size I did.

Post by Dave » August 25th, 2013, 8:47 am

Trimsaw thought

When cutting a slab on the trim saw, try turning the trim saw around so that you stand behind the saw and pull the slab toward you.

This eliminates most of the oil or water splattered all over you that you get if you try to push the slab toward the saw from in front.

You can also see what you are doing better when your glasses are not all oil splattered.

from NFMS Newsletter

Via Northside Gem and Hobby News 11/02