|

|

Post by Drummond Island Rocks on Sept 6, 2014 12:16:40 GMT -5

I just got my groove cutting bits yesterday and had to give it a quick try. This is just a scrap cab and scrap wire but I can at least see some potential.    Thanks for looking Chuck |

|

Tommy

Administrator

Member since January 2013

Posts: 12,989

|

Post by Tommy on Sept 6, 2014 12:22:04 GMT -5

Very nice start Chuck! I tried doing this and my first one came out completely crappy compared to yours. If you stay with it and it progresses like your other wrapping has it will looks stunning in no time at all.

Tommy

|

|

|

|

Post by Jugglerguy on Sept 6, 2014 15:11:18 GMT -5

That's nice, Chuck. I don't see any room for improvement,

|

|

|

|

Post by Drummond Island Rocks on Sept 6, 2014 15:51:06 GMT -5

That's nice, Chuck. I don't see any room for improvement, thanks Rob. I was pretty happy with the groove in the rock. Its very difficult to try to get an even depth all the way around the rock. I kept having to check the groove with scrap wire then go back to hit spots again. I am not sure how much I like the overall look compared to a conventional wrap but this method is about 10 minutes on the grinder, 10 minutes to wrap it and one foot of wire VS one of my normal full wraps at 45 minutes and 4 feet of wire. Chuck |

|

|

|

Post by orrum on Sept 6, 2014 16:03:17 GMT -5

X2 don't need improving!

|

|

|

|

Post by kap on Sept 6, 2014 19:38:48 GMT -5

NICE!!! Chuck are you using a grooving bit on a grinder? One thing I found that helps with the depth thing is I painted the bit and ground a groove the right depth and the paint wears off to that depth and you can see how deep you are grinding then. Hope it helps.

Keith

|

|

Thunder69

Cave Dweller  Thunder 2000-2015

Thunder 2000-2015

Member since January 2009

Posts: 3,105

|

Post by Thunder69 on Sept 6, 2014 20:08:12 GMT -5

Nice job on the groove...Yep the depth is a pain to get even all around..Keith I like your idea with the paint...I will do it the next time I get my groove on..LOL...John

|

|

cardiobill

freely admits to licking rocks

Member since March 2012

Posts: 881

|

Post by cardiobill on Sept 6, 2014 20:19:59 GMT -5

Looks spot on to me

|

|

|

|

Post by kap on Sept 6, 2014 20:24:00 GMT -5

I have used a marker it works also and is easy to touch up!

|

|

|

|

Post by rockjunquie on Sept 7, 2014 16:56:08 GMT -5

Great job! Better than mine! LOL! I have no talent for this.  What gauge are you using? |

|

Sandy

noticing nice landscape pebbles

Member since July 2014

Posts: 91

|

Post by Sandy on Sept 7, 2014 21:58:54 GMT -5

Looks good to me.

|

|

|

|

Post by Drummond Island Rocks on Sept 8, 2014 6:07:49 GMT -5

Great job! Better than mine! LOL! I have no talent for this.  What gauge are you using? I am using these bits "twofers" from the same supplier I get my wine stopper blanks from and 20 gauge wire square wire fits very well. Chuck |

|

panamark

fully equipped rock polisher

Member since September 2012

Posts: 1,343

|

Post by panamark on Sept 8, 2014 6:33:46 GMT -5

I want to start grooving too. I have often wondered if one couldn't put depth guide pegs/posts on the table like a router has. The piece rests against the post next to the cutting head and this controls the depth and keeps you from cutting too deep. Or maybe you can add a wider collar on the cutter so only the desired depth "sticks out"?

How long do these cutters last? Durability?

That is a nice job Chuck.

|

|

|

|

Post by Drummond Island Rocks on Sept 8, 2014 6:55:06 GMT -5

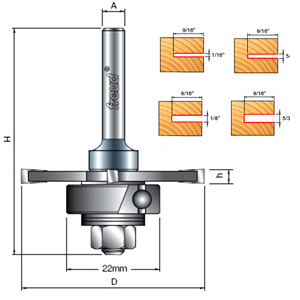

I want to start grooving too. I have often wondered if one couldn't put depth guide pegs/posts on the table like a router has. The piece rests against the post next to the cutting head and this controls the depth and keeps you from cutting too deep. Or maybe you can add a wider collar on the cutter so only the desired depth "sticks out"? How long do these cutters last? Durability? That is a nice job Chuck. Thanks mark I was also trying to relate this to my woodworking tools and router table. I think if a bit were designed specifically for this purpose you would have a ball bearing guide that only allows the cut to go to a certain depth. I cut my grooves before cabbing so the ball bearing portion would ride against the edge of the cab above the groove. In this woodworking illustration the ball bearing is right below the slot cutter so the slot depth is controlled.  Chuck |

|

panamark

fully equipped rock polisher

Member since September 2012

Posts: 1,343

|

Post by panamark on Sept 8, 2014 7:03:40 GMT -5

That is exactly what I was thinking of too.

If you build it, will the world beat a path to your door? LOL

Since rock won't burn like wood, maybe it won't need a bearing, just a polished hard surface and water would work find.

|

|

|

|

Post by Drummond Island Rocks on Sept 8, 2014 7:12:36 GMT -5

That is exactly what I was thinking of too. If you build it, will the world beat a path to your door? LOL Since rock won't burn like wood, maybe it won't need a bearing, just a polished hard surface and water would work find. If that were the case you may be able to have a slip fit collar made to go over the brass portion of these bits then just have two c'bored set screws to tighten it in place. that way when the cutter needs replaced you just take off the collar and install it on the new cutter.  Chuck |

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Sept 8, 2014 14:23:16 GMT -5

Very well done, nice flush of the contour wire on the edge of the cab.

Adrian

|

|

|

|

Post by Drummond Island Rocks on Sept 8, 2014 14:44:19 GMT -5

Very well done, nice flush of the contour wire on the edge of the cab. Adrian Thanks Adrian and thank you for the tutorial also. I have looked at that several times over the years and finally got the tools to try it. |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Sept 8, 2014 16:49:56 GMT -5

In lapidary the cutting is done by sacrificial materials. Even sintered diamond wears down and soon any bearing you may have will be too close to the outer rim of the cutter to allow a cut deep enough for the wire

|

|

|

|

Post by Drummond Island Rocks on Sept 8, 2014 16:56:49 GMT -5

In lapidary the cutting is done by sacrificial materials. Even sintered diamond wears down and soon any bearing you may have will be too close to the outer rim of the cutter to allow a cut deep enough for the wire Thats true if they are sintered but these do not say sintered anywhere on the packaging so I assume its just a plated disc where they wear out before the diameter changes. Someone that has used them a bunch can chime in on this one. Chuck |

|