jerrys

spending too much on rocks

Member since February 2014

Posts: 263

|

Post by jerrys on Sept 23, 2016 17:21:37 GMT -5

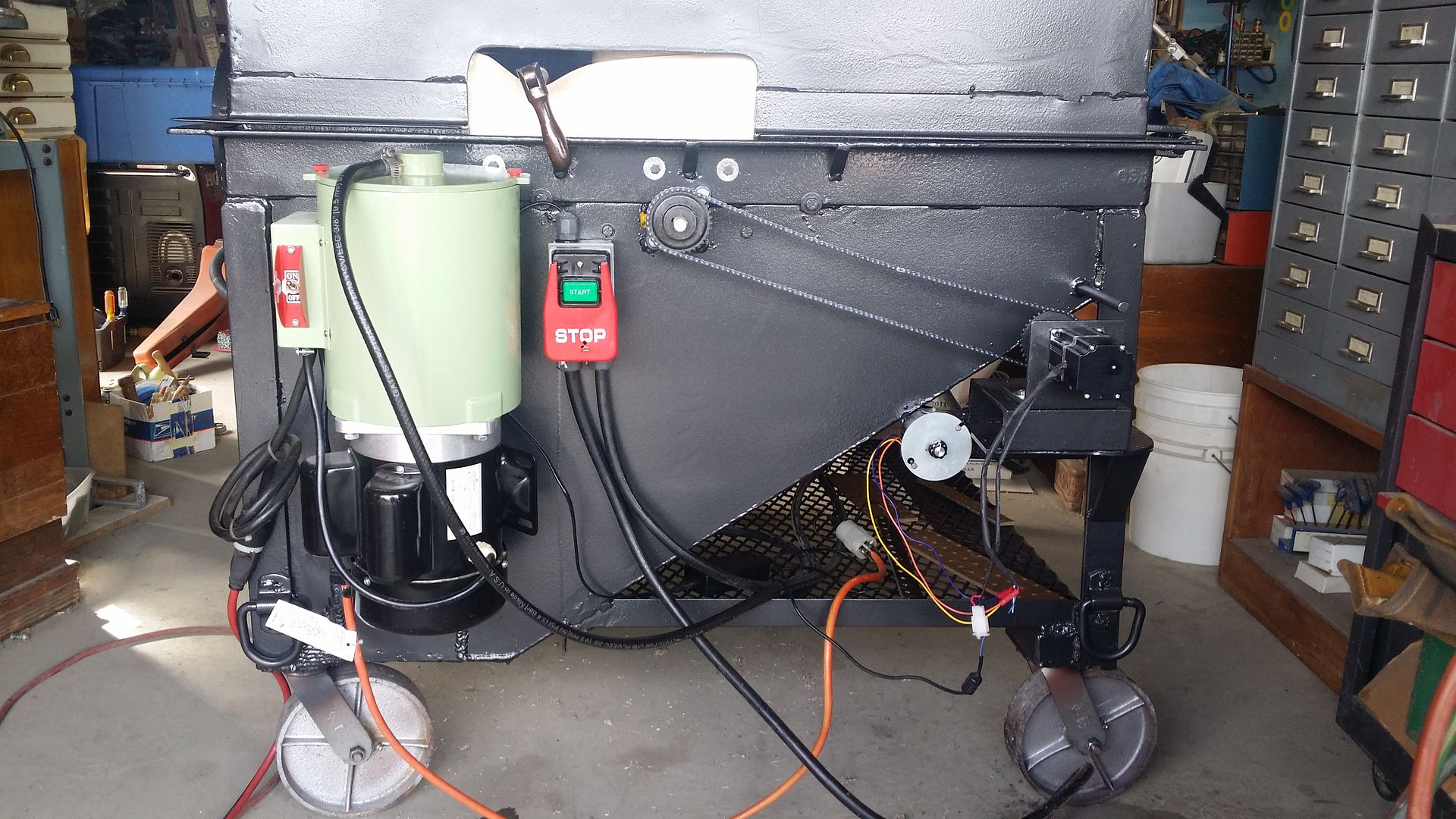

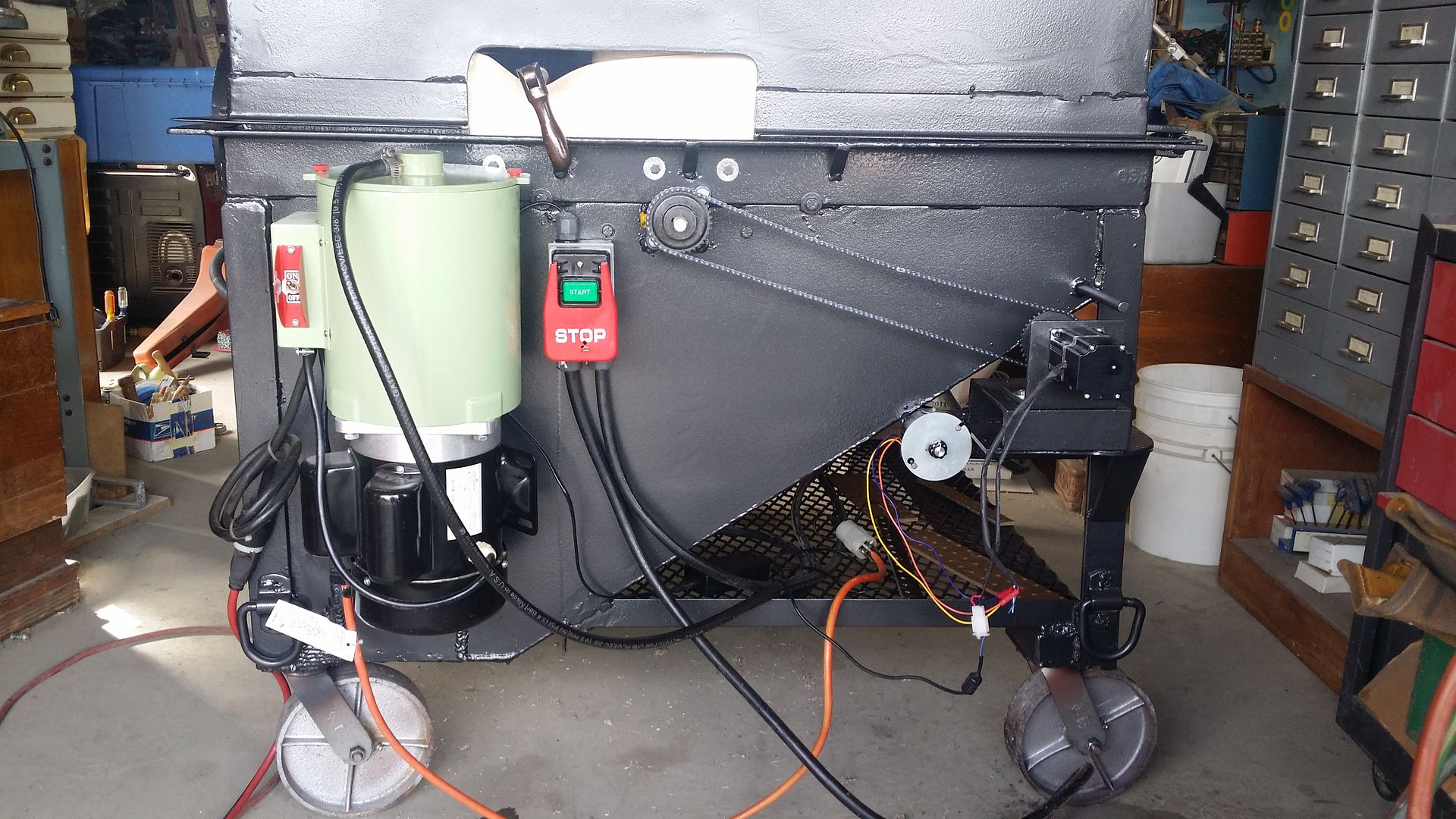

A friend and I have finished rebuilding a 30" rock saw. I believe it is a homemade saw using the Mohave kit and plans. I also believe that I'm the first to ever have it running due to the rework and work we completed. Thanks to roy for passing on a good deal. Here is a list of what we completed: - Installed an electric winch instead of using a counter balance to open the lid. The winch also works to load the saw in a trailer. - Replaced the plastic wheels with metal wheels - Straightened the legs and added the support bars and expanded metal decking to create storage shelf - Installed the oil cleaner - Installed a power switch with a shut off chain - Installed a DC motor controller and motor rated to drive 100 lbs. - Installed a 6 position switch so I can change the feed rate from 1/16", 1/8", 1/4", 5/16", 7/16", to 9/16" feed per minute. - Installed wood blocks on the vise - New belts - Replaced the feed drive bushings to bearings - Installed D rings to secure it during transportation - Paint - Wired it for 220V - Finally aligned the vise to the blade - It takes about 40 gallons of oil The first cuts were thundereggs and large turitella blocks. It has a very smooth cut. I was able to cut a 8.25" x 10.5" Succor Creek egg in 20 minutes. I need to tidy up the wiring but its been fun to cut the rock too big for the 24" saw.          |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Sept 23, 2016 18:42:21 GMT -5

If I didnt know it was a saw, that would be a killer grill!

Congrats on a great bit of work!

|

|

|

|

Post by captbob on Sept 23, 2016 18:54:59 GMT -5

Awesome! 40 gallons of oil?!  |

|

|

|

Post by Peruano on Sept 23, 2016 20:16:24 GMT -5

Beautiful saw but not quite enough photos for me to understand it all. The membranes on the drive shaft are just for keeping oil from creeping outside the case? Is there a belt guard missing from the side? I like rust brown instead of black but its your saw. Do you really need 40 gallons to cool it or just to cover the blade at the right depth (i.e. could you use bricks and other ballast to reduce that volume by half? I do notice that I get more mist when the temp of the blade (cut) increases, thus there is a real reason to keep temps down and rock/blade/oil temps moderated by volume and circulation. I'm envious of such a wonderful saw.

|

|

jerrys

spending too much on rocks

Member since February 2014

Posts: 263

|

Post by jerrys on Sept 24, 2016 14:33:16 GMT -5

When I bought the saw, it was already primer grey. With all the work we did, it was necessary to do an additional primer. The rust color is the primer. The finish is hammer tone black.

|

|

|

|

Post by woodman on Sept 25, 2016 16:45:48 GMT -5

I was wondering what size of moter do you have driving the blade? I have 1 1/2 HP 220 volts turning the blade on my 30 inch saw, and the motor heats up a fair bit. I am thinking about going to two HP.

|

|

zapins

starting to spend too much on rocks

Member since March 2016

Posts: 116

|

Post by zapins on Sept 26, 2016 0:58:29 GMT -5

Really nice job. Can you tell us a bit more about your oil filtering system?

I'd also love to see pics of the inside of the saw, how the apron slides on the rails and the seals for the feed screw. How did you manage speed control of the feed shaft?

|

|

jerrys

spending too much on rocks

Member since February 2014

Posts: 263

|

Post by jerrys on Sept 26, 2016 10:44:19 GMT -5

|

|

|

|

Post by roy on Sept 26, 2016 18:26:12 GMT -5

wow Jerry you did a great job on that saw have fun with it

|

|

zapins

starting to spend too much on rocks

Member since March 2016

Posts: 116

|

Post by zapins on Sept 28, 2016 22:54:13 GMT -5

Oh boy... now I have another machine to add to my list of things to DIY build. Centrifugal oil purification system here I come!

And what a neat controller system for the feed screw. I just bought a 2 RPM gear motor and two 3" pulleys, so my saw will only have 1 speed for now. I suppose I can always upgrade in the future and buy a controller just like your one if needed. Though I need to do some more reading on controlling an AC motor since I am only familiar with DC controllers.

...off to google up some plans.

|

|

jerrys

spending too much on rocks

Member since February 2014

Posts: 263

|

Post by jerrys on Oct 3, 2016 10:48:18 GMT -5

I was wondering what size of moter do you have driving the blade? I have 1 1/2 HP 220 volts turning the blade on my 30 inch saw, and the motor heats up a fair bit. I am thinking about going to two HP. It has a 2 HP motor. The motor gets warm. It would keep your coffee warm   |

|

|

|

Post by woodman on Oct 3, 2016 20:44:25 GMT -5

Thanks for the information, time to start looking for a 2 hp motor.

|

|

|

|

Post by Rockoonz on Oct 3, 2016 22:50:40 GMT -5

Another source for an oil cleaner. Made in USA and 1 gallon cans instead of the hard to find spendy 1/2 gallon www.easycleanllc.com/ |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,612

|

Post by jamesp on Oct 4, 2016 5:28:16 GMT -5

Impressive machine. Very rigid, should get some smooth cuts.

|

|

SirRoxalot

freely admits to licking rocks

Member since October 2003

Posts: 790

|

Post by SirRoxalot on Oct 29, 2016 16:27:27 GMT -5

Ridiculously cool that you're capable of doing all that work yourself, much respect.

I'd trade a kidney for a saw like that!

|

|