Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Jan 23, 2017 13:22:15 GMT -5

The feed dog on my Frantom was missing on purchase and the feed was operated by a spring clamp. When the spring clamp died, I could find no others with similar properties. At Q this weekend I learned that Diamond Pacific owned Frantom and all its engineering. Don was kind enough to hook me up with a brand new feed dog.  But I don't have the necessary ancillary parts to make it work. Does anyone have a Frantom with with working feed dog screw clamp? If so, would you please offer me an image of your clamp as it is set in place? I think I can make it fly from a simple pic. Orientation and how are the handles set for opening during reset are what I seek. A pic of the spring wouldn't hurt either. Oh and if your saw ain't 24" doesn't matter. I also learned all Frantom saws have the same feed dogs. So pics of the feed dog on any Frantom saw! Please and thank you. |

|

QuailRiver

fully equipped rock polisher

Member since May 2008

Posts: 1,640

|

Post by QuailRiver on Jan 23, 2017 14:58:34 GMT -5

I'm not sure if these photos will help you or not but I still had some photos of a 14" Frantom saw I sold a couple of years ago. So enlarged/cropped and brightened up the areas that partially show the feed screw mechanism for you.    Sorry there was no direct shot but hope this helps. Larry C. |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Jan 23, 2017 15:14:22 GMT -5

QuailRiverActually, that does indeed show the lever I needed to see and need to fabricate. Plus it shows orientation of clamp! Lastly, I see my spring is likely too long to be of much help. Need to source a shorter one. Still welcoming other pictures. This thread could help others too. Thanks Larry!! That was fast.

|

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Jan 23, 2017 15:24:54 GMT -5

I see I need some more visibility. The lever may have a cam on it to spread both sides of jaw. Or a slotted pin that on lifting spreads Both sides evenly.

|

|

quartz

Cave Dweller  breakin' rocks in the hot sun

breakin' rocks in the hot sun

Member since February 2010

Posts: 3,359

|

Post by quartz on Jan 24, 2017 16:29:50 GMT -5

@shotgunner, if you want, I can take the lever off my Frantom that fossilman passed on to me and send you an accurate tracing of it. I tried to get the whole assy. off the machine this A.M., but need to do a lot of rust busting before that. |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Jan 24, 2017 20:02:27 GMT -5

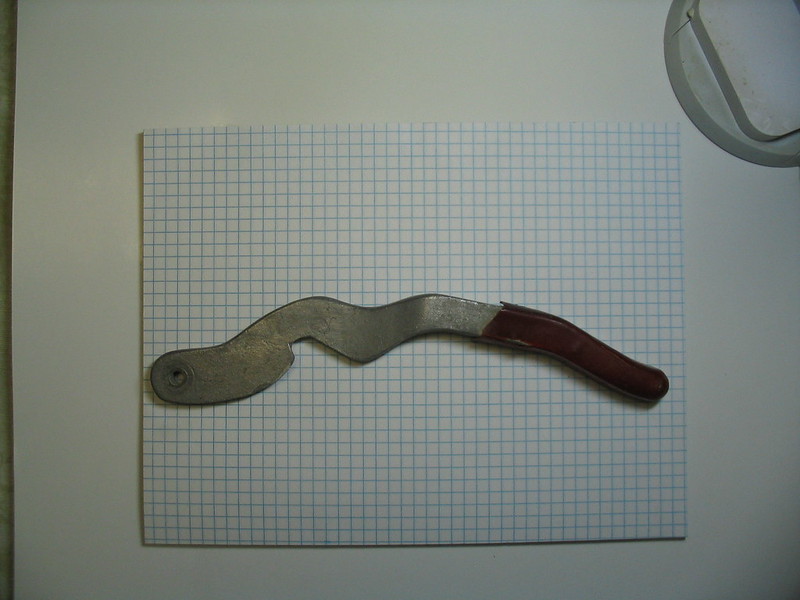

@shotgunner, if you want, I can take the lever off my Frantom that fossilman passed on to me and send you an accurate tracing of it. I tried to get the whole assy. off the machine this A.M., but need to do a lot of rust busting before that. Hi Larry; Up to you, but that would be amazing!! Even a pic on graph paper would suffice. Plus a pic of how it all goes together would be amazing too!! |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Jan 24, 2017 20:42:45 GMT -5

I think in am visualizing how it works. Clamps mounted on pins to rock sled. Handle mounted to one side of clamp and stop pin in the other. A cam on the handle spreads the threads apart allowing the sled to move freely. When released the spring closes the split nut alowwing metered feed!

|

|

quartz

Cave Dweller  breakin' rocks in the hot sun

breakin' rocks in the hot sun

Member since February 2010

Posts: 3,359

|

Post by quartz on Jan 25, 2017 0:30:12 GMT -5

I'll do it in the morning. The clamps are mounted to a plate that bolts on the sled.

|

|

quartz

Cave Dweller  breakin' rocks in the hot sun

breakin' rocks in the hot sun

Member since February 2010

Posts: 3,359

|

Post by quartz on Jan 25, 2017 16:10:03 GMT -5

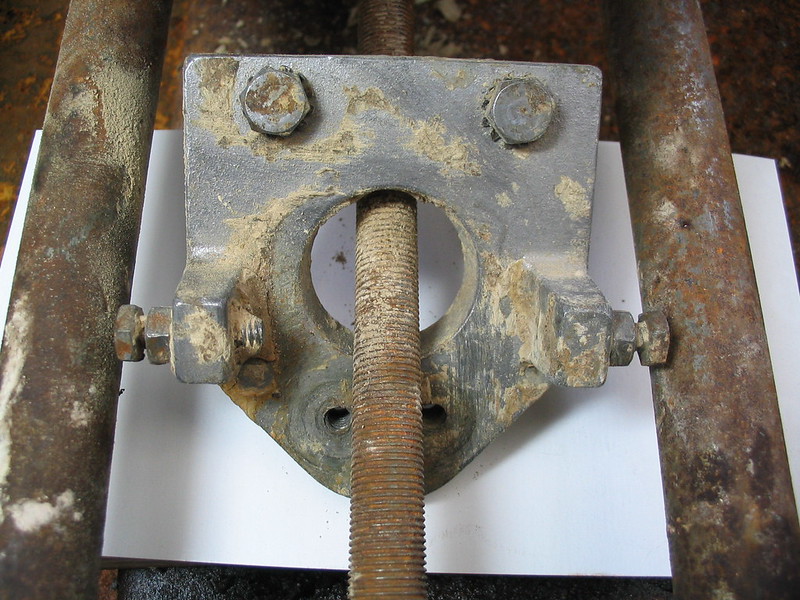

Here's some pics. of the feed parts: This is the plate that bolts to the back of the sled  Split nut, holes in bottom of nut bolt to, and pivot on, the two holes in the bottom of the plate.  Here is the lever:  The lever is bolted to, and pivots on, the left side of the split nut. On the right side of the split nut is a 1/4" bolt with a roller on it, the lever pushes on the roller. The lever, where it bolts to the split nut, is 3/8" thick. I'm going to trace the lever on the graph paper and snail mail it to you with a few notes on it, still have your address. Hope this helps. Larry |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Jan 25, 2017 19:27:37 GMT -5

Wow! Complicated.  Thanks Larry. You are the best! |

|

quartz

Cave Dweller  breakin' rocks in the hot sun

breakin' rocks in the hot sun

Member since February 2010

Posts: 3,359

|

Post by quartz on Jan 25, 2017 23:50:43 GMT -5

Really quite simple when you get it all laid out, 7/16 and 1/2 wrenches will get it done. I didn't show anything about the spring because mine is stretched too.

"The best" likely a matter of opinion, thanks, this is what we on the forum do for each other.

|

|

riverbendlapidary

fully equipped rock polisher

Member since September 2006

Posts: 1,058

|

Post by riverbendlapidary on Jan 26, 2017 19:20:56 GMT -5

|

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Jan 29, 2017 23:14:05 GMT -5

Thank you JR. May be worth buying the handle. |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Feb 1, 2017 21:11:47 GMT -5

I have Larry's drawing. Awesome!! Thank you kind sir!! quartz |

|

quartz

Cave Dweller  breakin' rocks in the hot sun

breakin' rocks in the hot sun

Member since February 2010

Posts: 3,359

|

Post by quartz on Feb 1, 2017 23:41:06 GMT -5

You're very welcome.

|

|