Homemade flat lap made from treadmill

Mar 10, 2017 1:34:35 GMT -5

captbob, Pat, and 2 more like this

Post by jm on Mar 10, 2017 1:34:35 GMT -5

Sticking with my theme of not buying anything that I can build myself, I recently put together a flat lap for polishing up some thundereggs and making cabs.

First, I found a free treadmill on Craigslist. It was an older one with a rotary dial for the speed controller, which works great for something like this. I've probably mentioned this in my other posts, but I love old treadmills for building equipment. They have fairly powerful DC motors and have a speed controller that is already matched up to the motor. The older ones tend to have a separate rotary dial for controlling the speed that can be easily detached from all the other electronics in the dashboard.

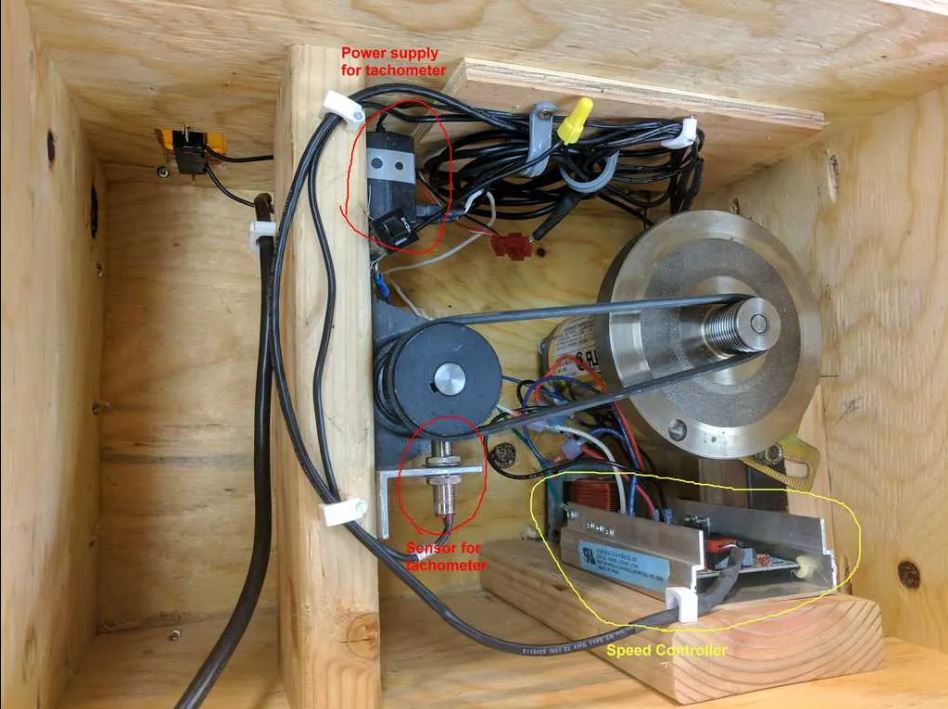

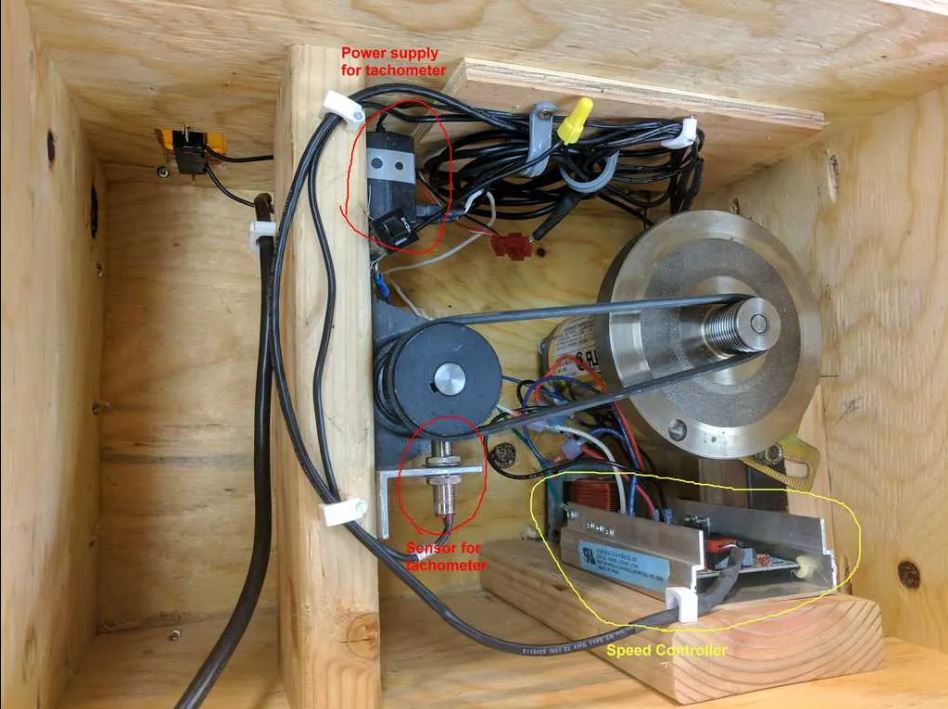

I built a plywood box and mounted the motor and speed controller inside. The motor uses the original pulley to drive a separate shaft that goes up through the top of the box. I picked up a digital tachometer off ebay for about $10 and found an old DC power supply in my garage and wired it in to supply 12VDC to the tachometer. The tachometer reads a magnet on the drive pulley so it shows the actual rpm of the lap disc.

Here's the view from the bottom of the box.

And a view from the top. The switch turns power on/off to the whole system, the rotary dial controls the rpm, which is displayed on the tachometer. The speed controller will spin the shaft anywhere from about 5 - 2700 rpm.

I used some drywall screws to attach a bowl to the top of the box, and used some silicon to attach a piece of 2" pvc pipe in the middle to keep water away from the shaft and bearings. There's some silicon on the drywall screws too, to keep it from leaking around them.

The water supply is just a water pitcher with a valve bolted into the bottom of it. It's held up by a piece of angle iron with a notch cut out of it for the handle of the pitcher to fit into. Zip ties hold the pitcher in place. It's set up so I can just slide the pitcher straight up to remove it. The water line is just a piece of rubber tube with about 4 ft of copper wire wrapped around it.

It took me a little while to come up with a good way to attach a drain to the bottom of the bowl, but finally came up with this. A piece of rubber tubing stuck onto a flanged T nut. I drilled a hole in the bottom of the bowl, through the plywood, and threaded the hose down through and pounded the nut into place. Some silicon keeps it from leaking.

The drain tube is only about 3/16" ID, so if it gets clogged up easily I'll replace it with a bigger tube.

I've already preformed a few cabs with it and it seems to work fine. Now I'm waiting on some finer grit lap discs to finish them up.

Total cost, not including the stuff I found laying around in the garage. A friend of mine who runs a machine shop provided the main shaft in exchange for a plate of home baked treats for the guys in the shop. Gotta love that kind of price.

Gotta love that kind of price.

tachometer - $10

bowl - $1

pitcher - $1

valve - $3

poly-v pulley - $8

2 pillow block bearings - $18

What do you think?

Questions and/or comments welcome.

First, I found a free treadmill on Craigslist. It was an older one with a rotary dial for the speed controller, which works great for something like this. I've probably mentioned this in my other posts, but I love old treadmills for building equipment. They have fairly powerful DC motors and have a speed controller that is already matched up to the motor. The older ones tend to have a separate rotary dial for controlling the speed that can be easily detached from all the other electronics in the dashboard.

I built a plywood box and mounted the motor and speed controller inside. The motor uses the original pulley to drive a separate shaft that goes up through the top of the box. I picked up a digital tachometer off ebay for about $10 and found an old DC power supply in my garage and wired it in to supply 12VDC to the tachometer. The tachometer reads a magnet on the drive pulley so it shows the actual rpm of the lap disc.

Here's the view from the bottom of the box.

And a view from the top. The switch turns power on/off to the whole system, the rotary dial controls the rpm, which is displayed on the tachometer. The speed controller will spin the shaft anywhere from about 5 - 2700 rpm.

I used some drywall screws to attach a bowl to the top of the box, and used some silicon to attach a piece of 2" pvc pipe in the middle to keep water away from the shaft and bearings. There's some silicon on the drywall screws too, to keep it from leaking around them.

The water supply is just a water pitcher with a valve bolted into the bottom of it. It's held up by a piece of angle iron with a notch cut out of it for the handle of the pitcher to fit into. Zip ties hold the pitcher in place. It's set up so I can just slide the pitcher straight up to remove it. The water line is just a piece of rubber tube with about 4 ft of copper wire wrapped around it.

It took me a little while to come up with a good way to attach a drain to the bottom of the bowl, but finally came up with this. A piece of rubber tubing stuck onto a flanged T nut. I drilled a hole in the bottom of the bowl, through the plywood, and threaded the hose down through and pounded the nut into place. Some silicon keeps it from leaking.

The drain tube is only about 3/16" ID, so if it gets clogged up easily I'll replace it with a bigger tube.

I've already preformed a few cabs with it and it seems to work fine. Now I'm waiting on some finer grit lap discs to finish them up.

Total cost, not including the stuff I found laying around in the garage. A friend of mine who runs a machine shop provided the main shaft in exchange for a plate of home baked treats for the guys in the shop.

Gotta love that kind of price.

Gotta love that kind of price.tachometer - $10

bowl - $1

pitcher - $1

valve - $3

poly-v pulley - $8

2 pillow block bearings - $18

What do you think?

Questions and/or comments welcome.