|

|

Post by Drummond Island Rocks on Sept 22, 2017 15:15:56 GMT -5

If you mount that blade back into the saw you can clamp a pencil in your vise to check it. Just clamp a pencil so that it barely touches the blade right under the rim and spin the blade by hand. see if the pencil lead stays on the blade or if it binds or gets gaps.

Chuck

|

|

meviva

Cave Dweller

Member since July 2013

Posts: 1,474

|

Post by meviva on Sept 22, 2017 16:07:20 GMT -5

captbob I called BD and the gave me a phone number to call. I talked with a nice guy and I need to inspect the clutch and the rod for thread damage. There was something else I was supposed to do but I can't remember. Before I do that though he said to try another adjustment and see if it will go the whole length without a rock in the vise. I'll see what I can do now but I have to run to the store I a little bit. I really have no clue what I'm doing so wish me luck. Andrea

|

|

|

|

Post by pauls on Sept 22, 2017 16:20:58 GMT -5

If you neeed to dismantle the clutch take photos of each stage of the dismantling so you can check where things go when you are assembling it again.

You probably wont need to check the photos because the act of setting up the photo makes it stick in your mind, crazy but it works.

|

|

|

|

Post by captbob on Sept 22, 2017 16:28:42 GMT -5

There was something else I was supposed to do but I can't remember.I really have no clue what I'm doing so wish me luck. LOL Good luck! It really shouldn't be that hard. Don't get too nervous about it, just a couple set screws and a phillips screw - you can do it! |

|

|

|

Post by aDave on Sept 22, 2017 16:29:29 GMT -5

If you neeed to dismantle the clutch take photos of each stage of the dismantling so you can check where things go when you are assembling it again. You probably wont need to check the photos because the act of setting up the photo makes it stick in your mind, crazy but it works. Great point. I find myself doing this all the time when dismantling something new. I usually take more photos than necessary, but I usually go by the rule that you can have too many photos. It's saved my butt a couple of times just with the odd shot picking up something that I didn't initially focus on. Dave |

|

meviva

Cave Dweller

Member since July 2013

Posts: 1,474

|

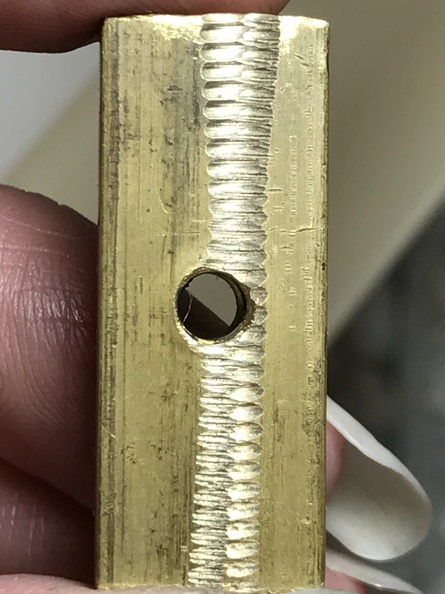

Post by meviva on Sept 22, 2017 20:24:17 GMT -5

captbob and anyone else who is interested. I got the brass clutch thingy out and this is what it looks like. I think it's messed up. I want to check the other part that's under the feed rod but I haven't figured out how to get it out yet. I want to see if it's damaged and needs to be replaced. I'm going to send the guy the pictures tomorrow to see what he says. Andrea

|

|

meviva

Cave Dweller

Member since July 2013

Posts: 1,474

|

Post by meviva on Sept 23, 2017 19:42:09 GMT -5

captbob Here is the other part. Not sure if it's bad. The BD guy said the other part has excessive wear. I sent this pic to him. I'll see what he says about it but I will probably order a couple of sets so I have a spare on hand.

|

|

|

|

Post by 1dave on Sept 23, 2017 20:56:55 GMT -5

With my third oil shower I put another switch in line with my saw. I ALWAYS turn it off until i AM READY TO CUT AGAIN.

|

|

|

|

Post by captbob on Sept 23, 2017 21:53:36 GMT -5

I'm thinking that second piece is messed up as well Andrea, with the way the ridges are flattened out near the edges. Important information will be if the guy you are in contact with can say why. Please pass along what he has to say on the matter. Doesn't seem to me that this should have happened so quickly.

Think I'll order these pieces as well just to have on hand should I ever need it.

Thank you for sharing your problem with us for the learning experience.

|

|

|

|

Post by TheRock on Sept 23, 2017 22:54:00 GMT -5

what model saw is your BD? Sorry for your loss. ~Duke

|

|

meviva

Cave Dweller

Member since July 2013

Posts: 1,474

|

Post by meviva on Sept 24, 2017 2:11:54 GMT -5

what model saw is your BD? Sorry for your loss. ~Duke It's an HP14. Thanks |

|

|

|

Post by 1dave on Sept 24, 2017 7:23:03 GMT -5

Highland Park was a great company until it was moved to China.

|

|

|

|

Post by captbob on Sept 24, 2017 8:00:26 GMT -5

|

|

|

|

Post by 1dave on Sept 24, 2017 8:12:30 GMT -5

Sorry, I just saw the HP. my error.

|

|

|

|

Post by captbob on Sept 24, 2017 8:16:17 GMT -5

Your statement is still correct!

|

|

meviva

Cave Dweller

Member since July 2013

Posts: 1,474

|

Post by meviva on Sept 24, 2017 9:13:23 GMT -5

I'm thinking that second piece is messed up as well Andrea, with the way the ridges are flattened out near the edges. Important information will be if the guy you are in contact with can say why. Please pass along what he has to say on the matter. Doesn't seem to me that this should have happened so quickly. Think I'll order these pieces as well just to have on hand should I ever need it. Thank you for sharing your problem with us for the learning experience. The BD guy says the second part looks ok. I thought it looked worn too. I'm still going to order both pieces to be sure. Besides that the second piece was a pain to get out. There is no room to work. We disconnected part of the carriage to see if that would help but that didn't give us any more room to work just a little better view. I will ask him what caused it. It might be just normal wear and tear. I use it a lot. If I'm in the rock room it's cutting something. Sometimes for hours a day. I just hope once I replace the parts I can adjust it properly. Because of the angle the screwdriver didn't get a good grip on this screw.  We used a wrench for the nut but because of the tight space I'm not sure how we are going to get it back together.  |

|

meviva

Cave Dweller

Member since July 2013

Posts: 1,474

|

Post by meviva on Sept 24, 2017 9:17:17 GMT -5

|

|

|

|

Post by captbob on Sept 24, 2017 9:45:30 GMT -5

Just out looking at mine Andrea and got to wondering if removing the ENTIRE carriage might be the way to work on this. I'm not about to disassemble everything right now just to see if it can be done, but if I had to get to that clutch shoe assembly, I might consider just unbolting the the entire assembly - have to disconnect the feed screw at the back and figure out how the rod with the pull to start knob is hooked up, but it sure would be easier to work on with the entire carriage out of the saw.

If you talk with the BD guy again, please ask him if this is a doable option. Don't see why not. Someone had to put it all together, so it must come apart in the reverse order.

|

|

|

|

Post by captbob on Sept 24, 2017 9:50:33 GMT -5

adding - looking at my clutch shoe (still assembled) the threads don't appear to be flattened out as they look to be towards the sides of yours here.  I know you say use yours a lot, but it's still less than 2 years old. That part shouldn't be worn out already! |

|

meviva

Cave Dweller

Member since July 2013

Posts: 1,474

|

Post by meviva on Sept 24, 2017 10:53:00 GMT -5

Just out looking at mine Andrea and got to wondering if removing the ENTIRE carriage might be the way to work on this. I'm not about to disassemble everything right now just to see if it can be done, but if I had to get to that clutch shoe assembly, I might consider just unbolting the the entire assembly - have to disconnect the feed screw at the back and figure out how the rod with the pull to start knob is hooked up, but it sure would be easier to work on with the entire carriage out of the saw. If you talk with the BD guy again, please ask him if this is a doable option. Don't see why not. Someone had to put it all together, so it must come apart in the reverse order. Definitely don't take it apart if you don't have to. Catmandewe has had problems adjusting his HP14. He has the same problem I do with the feed. I don't know if he has replaced the brass parts or not...but if it ain't broke, DON'T take it apart. I will ask the BD guy if taking out the whole carriage is an option. We did push over the rod that is just over the nut to give us a little more room. But the rail is the one that's really in the way. |

|