|

|

Post by TheRock on Nov 19, 2017 15:37:07 GMT -5

|

|

|

|

Post by Bluesky78987 on Nov 19, 2017 17:04:57 GMT -5

Sweet! Let us know how it works out!

|

|

unclesoska

freely admits to licking rocks

All those jade boulders tossed in search of gold!

All those jade boulders tossed in search of gold!

Member since February 2011

Posts: 934

|

Post by unclesoska on Nov 19, 2017 20:34:00 GMT -5

I recently sold my HF 10", only because I lost my shop space. I never put a lapidary blade on it, as I was using it mainly to cut grooves on thick slabs and some bevel work.

It's loud, but it eats thru the rock- will be following to see how the speed control works. At factory speed, it did chip a bit after the blade was broken in. Have fun!

|

|

kevin24018

spending too much on rocks

Member since February 2012

Posts: 284

|

Post by kevin24018 on Nov 20, 2017 8:27:35 GMT -5

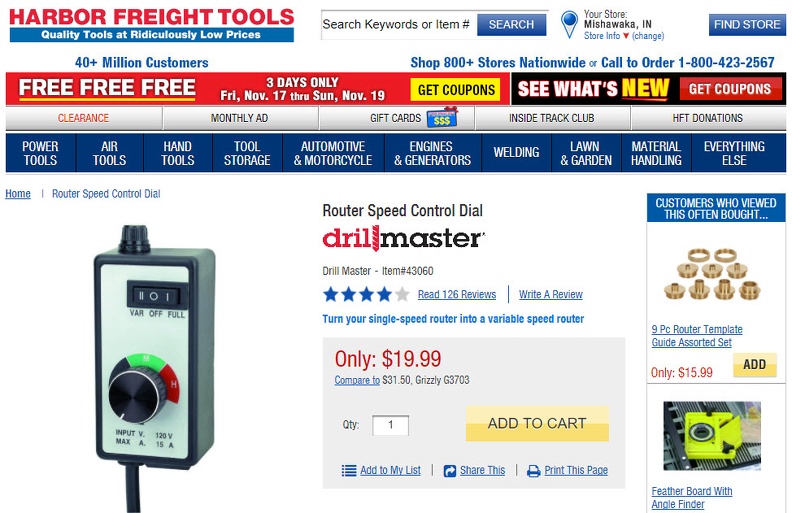

I seem to remember reading certain type of motors you should use a speed controller on. I can't recall the specifics but do a bit of research with the specs on that motor just to be sure before using that controller. Better to be safe than burn out the motor.

|

|

|

|

Post by TheRock on Nov 20, 2017 11:43:03 GMT -5

I seem to remember reading certain type of motors you should use a speed controller on. I can't recall the specifics but do a bit of research with the specs on that motor just to be sure before using that controller. Better to be safe than burn out the motor. You cannot use a speed control on an Induction type motor aka no brushes this motor has brushes same as a router. All is well  |

|

kevin24018

spending too much on rocks

Member since February 2012

Posts: 284

|

Post by kevin24018 on Nov 20, 2017 12:02:53 GMT -5

I seem to remember reading certain type of motors you should use a speed controller on. I can't recall the specifics but do a bit of research with the specs on that motor just to be sure before using that controller. Better to be safe than burn out the motor. You cannot use a speed control on an Induction type motor aka no brushes this motor has brushes same as a router. All is well  ah ok, good to know, thanks. |

|

|

|

Post by Psycho on Nov 20, 2017 13:29:29 GMT -5

I was thinking of this setup myself so I will follow to see how it works out

|

|

|

|

Post by Garage Rocker on Nov 20, 2017 14:39:36 GMT -5

Hey, Duke, I have this saw also. I had trouble using it until I added a vice onto it. I'm sure a resourceful guy like you can do a better job of it, but I went the down and dirty route. Sorry for the crappy low-light cell phone pics, but you'll get the idea.

|

|

kevin24018

spending too much on rocks

Member since February 2012

Posts: 284

|

Post by kevin24018 on Nov 20, 2017 15:21:50 GMT -5

Hey, Duke, I have this saw also. I had trouble using it until I added a vice onto it. I'm sure a resourceful guy like you can do a better job of it, but I went the down and dirty route. Sorry for the crappy low-light cell phone pics, but you'll get the idea.

neat, looks like you could hang a counter weight to pull it into the blade as well? |

|

trikepilot

off to a rocking start

Member since March 2018

Posts: 1

|

Post by trikepilot on Mar 8, 2018 18:17:27 GMT -5

Can I jump in here and ask how did the speed control work on that saw? Any better or worse results than the 3400 RPM it normally runs at? It has been a few months since the posting so have you had a chance to give it a workout?

|

|

NRG

fully equipped rock polisher

Member since February 2018

Posts: 1,688

|

Post by NRG on Mar 9, 2018 16:02:21 GMT -5

Hmmm.....

Wouldn't be that difficult to turn that saw into a gravity feed oil saw

|

|

|

|

Post by johnjsgems on Mar 12, 2018 10:44:11 GMT -5

I'm curious too. Back when a Japanese company made the wet polishers for Barranca they tested it (brush type motor) with router speed control. They found power was reduced significantly as well as motor life reduced. They advised against it. Also, if belt driven check speed with pulleys. My MK10 has a 3450 rpm motor but it is reduced to around 3000 with pulleys. Still pretty fast. You could pulley down to a more reasonable speed with no affect on motor. Covington orders the MK101 for a glass saw reduced to something like 2800 which is the slowest they can do and still use the cast belt guard.

|

|

|

|

Post by grumpybill on Mar 13, 2018 21:57:35 GMT -5

Excuse the off topic, but ...Covington orders the MK101 for a glass saw reduced to something like 2800... Does this mean that a saw should run slower for glass? When/if the weather ever warms up, I plan to slice up a bunch of glass slag and obsidian with my Diamant Boart tile saw. Should I calculate how much the pulleys are reducing the RPM and think about making some adjustments? |

|