jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Dec 31, 2017 15:50:27 GMT -5

These cost $60 each to build less electricity. Now have a 7,8,9 and 16 quart size. The 7,8,9 quart sizes have 6 inch entries. 16 quart is a 4 inch entry. Guessing the rock capacity to be about 60 pounds for all four. I intentional cut them down to have smaller barrels. The end cap side was cut shorter, not the reducer. Had they not been cut the combined capacity would have been over 100 pounds for the same cost. $240 for 100 pounds capacity is inexpensive. They should last a very long time. The 16 and 8 quart sizes have been running for over a week. They seem to be fine. Quit a bit quieter than harder PVC. Time to build about 30 minutes each, most of that was waiting for them to heat up for bonding. If they are heated a bit longer the connection can be made with about 20 seconds time to work on the alignment. Once aligned then weight was used, weight of my chest on floor while the round end was held in a dog food bowl.  |

|

|

|

Post by Drummond Island Rocks on Dec 31, 2017 16:12:27 GMT -5

Really nice work jamesp. I think those are going to be great barrels for your setup. Why 7,8 and 9 sizes instead of all 8's? seems the three sizes would confuse grit calculations. Chuck |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Dec 31, 2017 19:51:09 GMT -5

Really nice work jamesp. I think those are going to be great barrels for your setup. Why 7,8 and 9 sizes instead of all 8's? seems the three sizes would confuse grit calculations. Chuck The different sizes for one reason Chuck and that would be easy identification. Last time it was 5 PVC barrels and they were all exactly the same. Can't tell you how many times that confused the crap out of me. |

|

|

|

Post by youp50 on Dec 31, 2017 21:02:52 GMT -5

The caps could be numbered with a soldering or wood burning iron.

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Dec 31, 2017 23:13:27 GMT -5

The caps could be numbered with a soldering or wood burning iron. Pistol soldering iron melted letters in easily youp. |

|

|

|

Post by captbob on Jan 1, 2018 11:34:53 GMT -5

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Jan 1, 2018 20:13:18 GMT -5

Me sticking with the powdered polish Bob. It works and its reliable. Staying with the Rock Shed polish and various sizes of quartz pebble media. I would guess those alumina chunks would eventually become polished. HNY to you and yours, stay safe Bob.

|

|

|

|

Post by captbob on Jan 1, 2018 21:52:19 GMT -5

I would stick with the powder polish, but was thinking that that stuff could replace the silica based ceramic media I use. Seems the AO media would lay down a polish on it's own.

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Jan 5, 2018 6:03:32 GMT -5

I would stick with the powder polish, but was thinking that that stuff could replace the silica based ceramic media I use. Seems the AO media would lay down a polish on it's own. About all tumbling grade ceramic media is made out of AO. But it can also be made of zirconium oxide and a plethora of other ceramics. Aluminum oxide most common because it is cheap. Zirconium more expensive. Aluminum oxide is basically and simply a ceramic be it in powdered form or chunk form or media shapes. Yep, as that stuff became smoother it may lay a polish down. Maybe, depends on the particle size it is fused together from. Lots of ceramic media is fused from AO 60 particles and will never polish rocks, just wear a hole in your vibe. Same with media that has silicon carbide fused into it. Ceramic media fused together with polish size aluminum oxide will lay a polish down. Like the Rock Shed ceramic media. Quartz pea gravel is apparently composed of tiny particles since they transfer a fine polish. That zirconium oxide ceramic media tried to chop a hole in my Vibrasonic liner and that liner is made to run SiC 80. The salesman told me it was for polish, ha. 100's of types of ceramic media for tumbling. Some for grinding fast, some for polishing. Rock Shed sells the right media for polishing rocks. Don't experiment with ceramic media unless you do your research. The manufacturers sell it primarily for the metal industry, not many of them know about media for rocks. Your other (best and cheapest and safest)choice is quartz pea gravel. Tumble polish good quartz pea gravel as you would your ceramic media and you are good to go. I rarely use media in coarse grind, but always use it in the vibe. A mix of rock sizes will suffice for coarse grind. Lest you are tumbling a big rock or obsidian/soft rocks. |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Jan 5, 2018 6:28:51 GMT -5

The caps could be numbered with a soldering or wood burning iron. I cut you short youp, I did grind big Roman numerals 1 thru 5 in the old PVC barrels with a 4.5 inch hand grinder. I had to turn the tumbler on and off to see the numbers. Me lazy. So this time I just made the barrels in increments of 1 inch longer so I could discriminate with them rolling. The HDPE is wicked when used for tumble barrels. I have been tumbling a couple of test chunks of HDPE to check it's wear rate. Tumbling barely effects it. Not PVC, it wears when tumbled. PVC makes a lot of noise rolling on my bare steel shafts, the HDPE runs quiet. And way less noise from the rocks. It says High Density, but much softer than PVC, so quieter. Never seen such a rugged tumbling barrel. I even tumbled a half load of 1.5 inch steel balls dry with bulk SiC dry to make fine SiC grit(ball mill). 2 hours time and the bulk SiC was turned into about 100% 1000 grit lol. Those balls would have shattered the PVC barrels. I could make powdered anything with that rig. I got some stumps to remove. I'll be making powdered aluminum explosive. Will blast them. BOOM !! Eat your heart out ATF. Life short. |

|

|

|

Post by toiv0 on Jan 5, 2018 7:42:20 GMT -5

The caps could be numbered with a soldering or wood burning iron. I cut you short youp, I did grind big Roman numerals 1 thru 5 in the old PVC barrels with a 4.5 inch hand grinder. I had to turn the tumbler on and off to see the numbers. Me lazy. So this time I just made the barrels in increments of 1 inch longer so I could discriminate with them rolling. The HDPE is wicked when used for tumble barrels. I have been tumbling a couple of test chunks of HDPE to check it's wear rate. Tumbling barely effects it. Not PVC, it wears when tumbled. PVC makes a lot of noise rolling on my bare steel shafts, the HDPE runs quiet. And way less noise from the rocks. It says High Density, but much softer than PVC, so quieter. Never seen such a rugged tumbling barrel. I even tumbled a half load of 1.5 inch steel balls dry with bulk SiC dry to make fine SiC grit(ball mill). 2 hours time and the bulk SiC was turned into about 100% 1000 grit lol. Those balls would have shattered the PVC barrels. I could make powdered anything with that rig. I got some stumps to remove. I'll be making powdered aluminum explosive. Will blast them. BOOM !! Eat your heart out ATF. Life short. Well a cheap " ball mill " might be just the ticket for what phil is looking for. phil what do you think? |

|

|

|

Post by 1dave on Jan 5, 2018 8:25:38 GMT -5

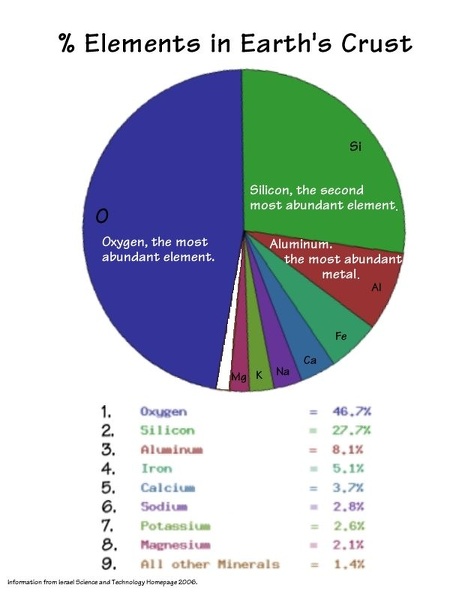

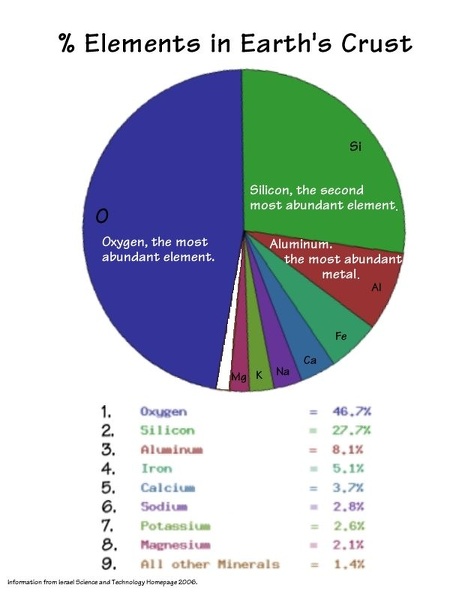

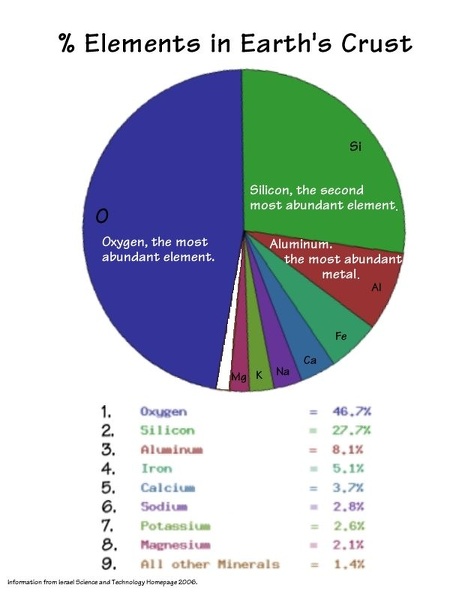

Just thinking about availability and price. Earth's surface rocks are mostly silicon and aluminum oxide. everything else has to be more expensive.  |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Jan 5, 2018 9:53:23 GMT -5

Just thinking about availability and price. Earth's surface rocks are mostly silicon and aluminum oxide. everything else has to be more expensive.  Lots of aluminum rich white clay in Georgia. 30% alum ox  |

|

|

|

Post by phil on Jan 5, 2018 13:12:35 GMT -5

]Well a cheap " ball mill " might be just the ticket for what phil is looking for. phil what do you think? Maybe. Committed to building the grinding mill now. bought everything, just need warm day to work in garage. Maybe if this grinder doesn't work... Thanks! |

|

|

|

Post by youp50 on Jan 5, 2018 15:07:20 GMT -5

If you could see some of the slurries pumped through it at mines and processing facilities you would be amazed. Liquid sand paper. The only problem with the HDPE is supporting the stuff. Building trays is expensive. There will always be a use for rubber lined steel pipe.

Now there is a new direction for you to go. Build an autoclave and learn to vulcanize rubber onto the interior of common steel pipe.

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Jan 9, 2018 2:22:17 GMT -5

If you could see some of the slurries pumped through it at mines and processing facilities you would be amazed. Liquid sand paper. The only problem with the HDPE is supporting the stuff. Building trays is expensive. There will always be a use for rubber lined steel pipe. Now there is a new direction for you to go. Build an autoclave and learn to vulcanize rubber onto the interior of common steel pipe. HDPE still smooth on the inside youp. The internal weld bead should give a good indication of wear resistance since it sticks out prominent. Another abrasion issue is dirty abrasive water falling down a pond overflow. Note 4 way at bottom of riser to hold water to prevent overflow from wearing a hole in the PVC pipe.  |

|

|

|

Post by youp50 on Jan 9, 2018 4:10:23 GMT -5

Similar arrangement where slurries drop into launders. Not a cross, no need to drain. It drops into a tee with the bottom capped. A 45 on the side outlet pointed down. The idea is the same, use the solids in the fluid to build up a wear resistant plug. The fittings and launders are rubber lined steel. The drop pipe is wire reinforced rubber.

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Jan 9, 2018 9:56:31 GMT -5

Similar arrangement where slurries drop into launders. Not a cross, no need to drain. It drops into a tee with the bottom capped. A 45 on the side outlet pointed down. The idea is the same, use the solids in the fluid to build up a wear resistant plug. The fittings and launders are rubber lined steel. The drop pipe is wire reinforced rubber. youp been there done that. I should have known. They put me in charge of the ironworkers, pipe fitters and millwrights when we did a plant expansion. Of all those workers the pipe fitters were, well, let's say they stuck to their union rights the most. I figured it safe to tip toe around them lol. Not your chummiest bunch. I never gained their respect as a college boy manager. They didn't need me as they knew what they were doing. Well enough. Posted the drawings on the wall and left them the hell alone. I don't remember them ever making a mistake. Even the ironworkers tip toed around them. I'm not stupid. |

|

|

|

Post by 1dave on Jan 9, 2018 11:09:39 GMT -5

Similar arrangement where slurries drop into launders. Not a cross, no need to drain. It drops into a tee with the bottom capped. A 45 on the side outlet pointed down. The idea is the same, use the solids in the fluid to build up a wear resistant plug. The fittings and launders are rubber lined steel. The drop pipe is wire reinforced rubber. youp been there done that. I should have known. They put me in charge of the ironworkers, pipe fitters and millwrights when we did a plant expansion. Of all those workers the pipe fitters were, well, let's say they stuck to their union rights the most. I figured it safe to tip toe around them lol. Not your chummiest bunch. I never gained their respect as a college boy manager. They didn't need me as they knew what they were doing. Well enough. Posted the drawings on the wall and left them the hell alone. I don't remember them ever making a mistake. Even the ironworkers tip toed around them. I'm not stupid. We (electricians) feared the Iron workers the most. Screw with one of them and they would get the height on you and "accidentally" drop something that could put a hole in your hard hat. |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Jan 9, 2018 13:30:49 GMT -5

youp been there done that. I should have known. They put me in charge of the ironworkers, pipe fitters and millwrights when we did a plant expansion. Of all those workers the pipe fitters were, well, let's say they stuck to their union rights the most. I figured it safe to tip toe around them lol. Not your chummiest bunch. I never gained their respect as a college boy manager. They didn't need me as they knew what they were doing. Well enough. Posted the drawings on the wall and left them the hell alone. I don't remember them ever making a mistake. Even the ironworkers tip toed around them. I'm not stupid. We (electricians) feared the Iron workers the most. Screw with one of them and they would get the height on you and "accidentally" drop something that could put a hole in your hard hat. Apparently the pipe guys were the grumpiest in this area lol. Had some playful iron workers. Wild bunch the all of them. I snuck up behind the boss iron worker one Saturday morning and scared the pop out of him. To my surprise the cannonball shaped man almost ran my long legged butt down. The others said he was fast on his feet. I think he wanted to grind my bones that moment, thanked God for my escape. |

|