caroleanniemt

off to a rocking start

Member since August 2018

Posts: 2

|

Post by caroleanniemt on Aug 3, 2018 22:02:17 GMT -5

Hello!

I have an older 10" Covington slab/trim saw I bought on ebay about a year ago for which I fitted with a new Barranca BD-303 blade. I cut agates and petrified wood pretty much exclusively. The saw has been running great, but recently, when cutting a larger agate ~3in, the rock started 'climbing' up on to the blade. the arm that travels on the auto feed with the vise is lifting off the table as it cuts. Not only is it making for a bad cut but it is causing terrible wear on my blade. It seems like the feed is moving the rock faster than the blade can cut into it, but I'm not sure what changed. I dress the blade regularly.

My thinking is that I need a better blade? any suggestions?

Thank you!

|

|

|

|

Post by stardiamond on Aug 3, 2018 22:11:38 GMT -5

I have a 16 inch Covington combo saw and I hate it. I don't know about the feed on your saw. Mine has an adjustable clutch. I've talked it Covington multiple times and I'm suppose to adjust the clutch to slow the feed and regularly dress the blade. I've ruined two blades. Their latest suggestion was to use a MK301 blade, bought but haven't installed it. The blade is suppose to last longer and do a better job cutting hard amterial My previous blades were the original Covington blade and a MK303.

|

|

|

|

Post by deb193redux on Aug 4, 2018 0:42:27 GMT -5

I think the blade needs more than conditioning. it needs to have the edge flattened. I think it is called swedging. You can also change gears to spin blade about 10% faster. it is climbing because it is not cutting fast enough.

|

|

|

|

Post by Peruano on Aug 4, 2018 7:44:15 GMT -5

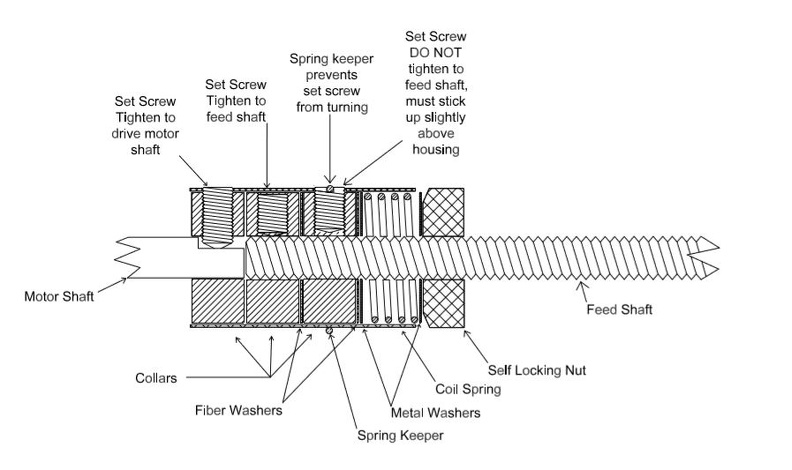

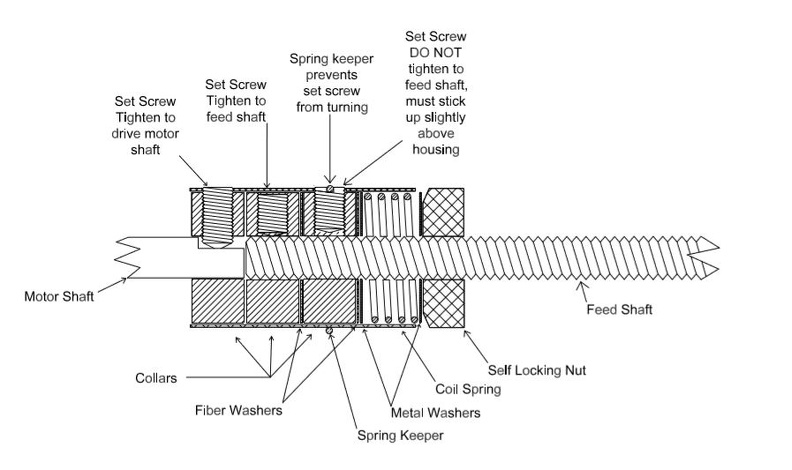

The clutch on the Covington saws (those that have one) are complex and need to be adjusted correctly or they lend themselves to stalling or doing as described (pushing too fast for the blade to make adequate cut progress). The above diagram of the clutch should allow you to see that yours is assembled correctly; they often are disassembled and chaotically reassembled with less than beneficial results. The clutch is made to slip to varying degrees depending on the tension placed on that spring. Its somewhat of a cross between a manual clutch on your gmc pickup and the automatic cluch that was in grandpa's 54 Desoto. BTW I can take minimal credit for this drawing; it was done by Vic who used to do cad work in another life (before lapidary). |

|

caroleanniemt

off to a rocking start

Member since August 2018

Posts: 2

|

Post by caroleanniemt on Aug 4, 2018 8:09:17 GMT -5

Thanks for the responses! I will take a look at the clutch

|

|

|

|

Post by stardiamond on Aug 4, 2018 13:00:57 GMT -5

This is what happened when I quit using my blade. Loosen clutch, blade turns rock doesn't cut. Tighten clutch, blade binds. Do finger nail test and feel bumps, before and after dressing. Try to reverse blade and blade wobbles. It didn't wobble before. Most likely situation is the blade was worn out, but I don't think I got recommended usage. I'm pretty sure that the saw will work fine with new blade.

|

|

Sabre52

Cave Dweller  Me and my gal, Rosie

Me and my gal, Rosie

Member since August 2005

Posts: 20,503

|

Post by Sabre52 on Aug 8, 2018 8:41:46 GMT -5

My P.O.S 10" Covington saw is the reason I'm getting out of the lapidary hobby. Constantly repairing the damn thing and having to sit by it and listen for it's latest F' up was just causing me stress and spoiling my days. More fun not to cut rocks!. Got other hobbies that are actually fun and now I have so much more time. Lapidary is neat but it is a time consuming hobby. Cutting and grinding rocks is a sloooooooooow process..Mel

|

|

|

|

Post by fantastic5 on Aug 8, 2018 8:55:47 GMT -5

My 10in Raytech auto feed slab saw has a clip, for the lack of a better word, that slides under the table where the blade comes through. I hadn't realized it, but at one point I pushed the rock clamp carriage all the way to the back, which allowed the little c- shaped clip to come out of the hole. It took several attempts at cutting and having the rock climb the blade, before I realized what happened. I'm not familiar with the Covington saw, but maybe you have a similar clip that holds the rock clamp carriage down to the table.

|

|

|

|

Post by johnjsgems on Aug 8, 2018 10:51:56 GMT -5

Put a 301 blade on it and most of the finicky clutch issues will be resolved. Don't reverse 303C or 301 blades. Hammering edge flat also good advise if blade edge is rounded.

|

|

|

|

Post by victor1941 on Aug 8, 2018 13:59:01 GMT -5

Carol, I would swedge the blade and then cut about 12-20 square inches through a coarse grinding wheel. I swedge by taking the blade off the machine and then tapping the edge with a ball peen hammer until the edge is not u shaped. I then check the top cutting edge by running the tip of my fingernail to check for roughness(diamonds). If this doesn't work and you haven't adjusted the clutch then your blade needs to be replaced. Sharpening the blade is different than swedging because hammering flattens the front surface and allows for a wide kerf.

|

|

NRG

fully equipped rock polisher

Member since February 2018

Posts: 1,688

|

Post by NRG on Sept 16, 2018 12:24:31 GMT -5

The clutch on the Covington saws (those that have one) are complex and need to be adjusted correctly or they lend themselves to stalling or doing as described (pushing too fast for the blade to make adequate cut progress). The above diagram of the clutch should allow you to see that yours is assembled correctly; they often are disassembled and chaotically reassembled with less than beneficial results. The clutch is made to slip to varying degrees depending on the tension placed on that spring. Its somewhat of a cross between a manual clutch on your gmc pickup and the automatic cluch that was in grandpa's 54 Desoto. BTW I can take minimal credit for this drawing; it was done by Vic who used to do cad work in another life (before lapidary). Thanks for this. Where is said clutch found on the saw? |

|

|

|

Post by Peruano on Sept 17, 2018 7:36:46 GMT -5

The Covington clutch is in the back of the saw in the screw feed for the vice (i.e. the long threaded rod that runs the length of the saw and on which the split nut clamps).

|

|

minerken

Cave Dweller

Member since August 2013

Posts: 466

|

Post by minerken on Sept 17, 2018 12:23:02 GMT -5

FWIW I had the dreaded climb the blade problem on my old beacon star tried all the above which are very good advise. I came to the conclusion that there should be no perceptible lifting of the rock if the vise was firmly attached to the guide rails, wiggle your vise side to side and up and down if there is any play it will allow the rock to be able to move up or down or side to side. In my particular case the vise runs on round rods and upon inspection I found that the holes that the rods run through were wallowed out. I am not familiar with the Covington vise system but if there is an adjustment that you can use for tightening the vise that is good but if it is wear you may need to replace or modify something. In my case I had to re-drill the holes and add a bushing. With all this being said I then had to go back and readjust all the above suggestions a worn part will have a domino effect. Good luck

|

|

mikeinsjc

spending too much on rocks

Member since June 2010

Posts: 329

|

Post by mikeinsjc on Oct 25, 2018 20:13:22 GMT -5

Carol,

I have cut many thousands of square inches of material on a 18" Covington saw and here is my solution;

Sell it.

I'm not familiar with your saw, but the weaknesses on the 18" saw are legion so I don't assume your model is much different.

Don't take apart the clutch system. It is easy to mess up and difficult to get adjusted properly. The vise is the poorest of any commercial saw I've seen. It is difficult to tighten adequately to insure your rock isn't going to come loose and play Pacman with your blade. I ended up using a c-clamp or bar clamp across the top of the vise to give additional clamping force. All the components on the carriage are light duty compared to any other 18" saw on the market. I would pay twice as much for a 18" HP or Frantom over a Covington.

|

|