Inca Red Clay used for perfecting their stone masonry

Apr 15, 2019 7:04:25 GMT -5

mohs, grumpybill, and 1 more like this

Post by 1dave on Apr 15, 2019 7:04:25 GMT -5

www.academia.edu/37497925/On_the_reddish_glittery_mud_the_Inca_used_for_perfecting_their_stone_masonry

H. Tributsch

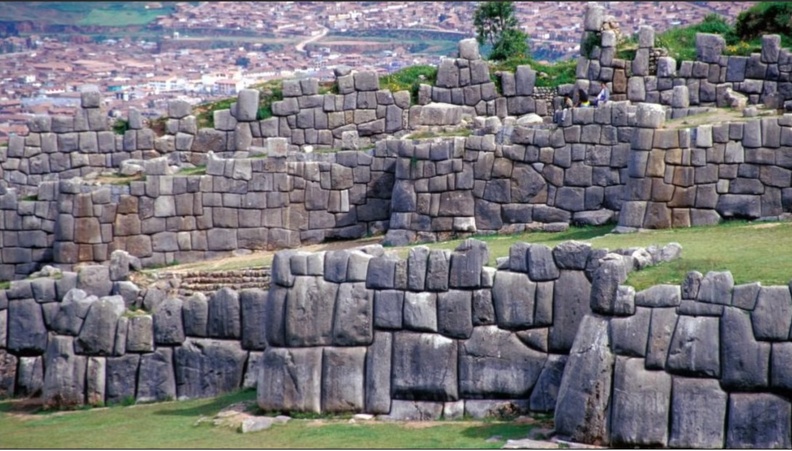

Due to its impressive appearance, Inca masonry, which mostly consists of volcanic, silica containing rock material, has received much attention. A high level of understanding has consequently been reached of the diverse working steps and tools applied.

An exception is the reddish mud, “llancac alpa” in the quechua language, and the “gold”, mentioned by early chroniclers as mortar which fitted the stones and later disappeared. Such techniques were related to folklore and not taken seriously.

This study tries to understand them and the question was asked:

did Inca builders have access to very acid mud?

They did, and used the acid mud from their mines, which generated sulphuric acid through bacterial oxidation of pyrite (fools gold). It reaches an acidity of up to pH = 0.5, which is 104 times more acid than humic acid which is known to weather silica containing rocks via silica gel to the clay mineral kaolin. This acid mud allowed dissolving and softening the rock material superficially to a viscoelastic silica gel. The process could be further enhanced more than tenfold by addition of (oxalic acid containing) plant sap, a skill suggested from popular tradition.

In special cases moderate heating of crushed pyrite in gaps between chiselled stones generated additional hot sulphuric acid. Where the stone to stone contact transmitted weight, pressure dissolution in the acidic environment removed material, and silica precipitation regenerated material in cracks and pores elsewhere. It is attempted to reconstruct how the Inca builders applied the silica gel technology for shaping stones, for polishing and fitting them. The appearance of shiny and glassy Inca stone junctions and interfaces is explained via solidification of in-situ generated or additionally added silica gel. Modern processes for conservation of stone monuments against environmental deterioration have independently developed similar silica gel based technology.

Due to its impressive appearance, Inca masonry, which mostly consists of volcanic, silica containing rock material, has received much attention. A high level of understanding has consequently been reached of the diverse working steps and tools applied.

An exception is the reddish mud, “llancac alpa” in the quechua language, and the “gold”, mentioned by early chroniclers as mortar which fitted the stones and later disappeared. Such techniques were related to folklore and not taken seriously.

This study tries to understand them and the question was asked:

did Inca builders have access to very acid mud?

They did, and used the acid mud from their mines, which generated sulphuric acid through bacterial oxidation of pyrite (fools gold). It reaches an acidity of up to pH = 0.5, which is 104 times more acid than humic acid which is known to weather silica containing rocks via silica gel to the clay mineral kaolin. This acid mud allowed dissolving and softening the rock material superficially to a viscoelastic silica gel. The process could be further enhanced more than tenfold by addition of (oxalic acid containing) plant sap, a skill suggested from popular tradition.

In special cases moderate heating of crushed pyrite in gaps between chiselled stones generated additional hot sulphuric acid. Where the stone to stone contact transmitted weight, pressure dissolution in the acidic environment removed material, and silica precipitation regenerated material in cracks and pores elsewhere. It is attempted to reconstruct how the Inca builders applied the silica gel technology for shaping stones, for polishing and fitting them. The appearance of shiny and glassy Inca stone junctions and interfaces is explained via solidification of in-situ generated or additionally added silica gel. Modern processes for conservation of stone monuments against environmental deterioration have independently developed similar silica gel based technology.