jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Mar 14, 2020 7:38:51 GMT -5

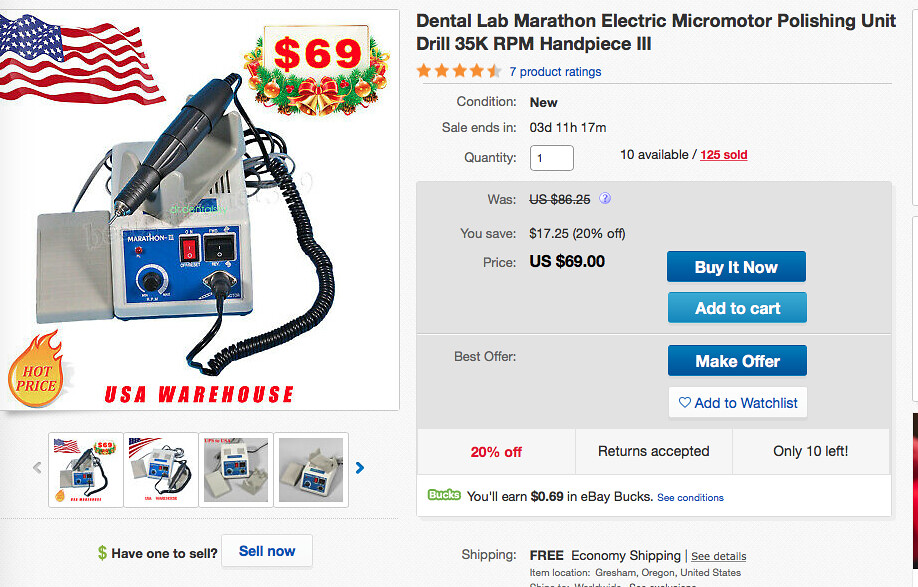

Goal: To get a 1.6mm diamond dental bit to fit and work well with a 35,000+ rpm work piece. I purchased a 35,000 DC work piece motor drill that has a snap-to-clamp 2.3mm collet. It came with a speed control/reversing box. This workpiece is not the best quality. Other better units plug in to the universal control box. But it proved the point that 35,000 rpm coupled with the 1.6mm bits cut hard material like butter and low pressure. The diamond dental bits are so cheap at 19 cents each and very sharp but they have a 1.6mm shank that are too small to clamp in the 2.3mm collet. It appears a 1.6mm collet would fit where the 2.3mm collet fits in the high speed work piece. Has any one ever used these 1.6mm 'dental' labeled diamond bit sizes ? It is the 1.6mm bits that perform best for me. I did buy a tiny adaptor chuck that will hold a 1.6mm bit shank. It has a 2.3mm shaft to fit in the 2.3mm collet but introduces vibration due to it's extended length or out-of-roundness at 35,000 rpm. This is the chuck and end of the EBAY workpiece.    These 1.6mm shank bits are totally sharp and spin true at high speed  |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Mar 14, 2020 8:02:11 GMT -5

It may be that the smaller 1.6mm shank bits are designed for pneumatic work pieces. Upwards of 400,000 rpm.

All of the electric work pieces seem to be built with collets to clamp 2.35mm shank bits and speeds up to 60,000 rpm.

The 1.6mm clamped into the electric work piece via optional mini-chuck preformed incredibly well at only 35,000 rpm excepting the shaft vibration added by the chuck.

A shame if the 1.6mm bits can not be adapted to the electric units.

|

|

|

|

Post by knave on Mar 14, 2020 8:13:10 GMT -5

jamespI ordered the dental bits and used one of the smaller collets to chuck it directly into my variable speed dremel, it performed flawlessly with no wobble. ETA I believe the max speed is 35k rpms but I ran it at a medium speed

|

|

EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Mar 14, 2020 9:49:26 GMT -5

Looks like almost all of them would be coming from another country. We don't make anything here anymore  |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Mar 14, 2020 10:02:09 GMT -5

Tickled to have a crop of young engineers to figure stuff out EricD and knave. I am getting great holes and drilling rates with the higher rpm/low pressure/super sharp bits method Evan. Hope to try a 60,000 rpm drill. Shopping. would really like to try a dentist's pnuematic rolling at 300,000+ rpm but concerned about cost and maintenance. I ordered this adaptor Eric. It is minimal and lightweight, looks like it should spin true at 35 t0 60,000. Big help you guys thanks. |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Mar 14, 2020 10:21:18 GMT -5

Looks like almost all of them would be coming from another country. We don't make anything here anymore  Ha, a dried up country. It all comes from the other side. I wish they made a solid 3 split 1.6mm collet that clamps just like the solid 3 split 2.35mm collet that comes with the drill. The solid collet is the ultimate high speed setup. And my drill has a twist feature, a quick twist clamps the collet, untwist and it releases the bit/collet. |

|

|

|

Post by knave on Mar 14, 2020 10:34:02 GMT -5

Apparently, I do!

|

|

EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Mar 14, 2020 19:44:54 GMT -5

A dremel can be fitted with any size collet Jim. It spins at 35k RPM maximum which I believe would be plenty for your needs, if the bit isn't dull. Heck, I drill my crappy holes at 180RPM

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Mar 16, 2020 10:18:19 GMT -5

A dremel can be fitted with any size collet Jim. It spins at 35k RPM maximum which I believe would be plenty for your needs, if the bit isn't dull. Heck, I drill my crappy holes at 180RPM Not had good luck with high speed drills ! I have had best drilling efficiency with higher rpm. That is my goal. My dentist even helped me and did test some holes in glass with her bits. AMAZING. She says teeth are way tougher than glass. Creating more confidence with higher speeds. The high speed Saga: I started with the two Dremels I had. One is like a 3000, the other a 4000. Both had bit wobble starting at 10,000 to 12,000 rpm causing hole breakage. So I bought a Rio Grande drill press. It is super smooth to it's maximum speed of 8000 rpm plus it has more torque for pushing 3mm and 4mm drills thru thicker glass. Slow going with 1.2mm to 2mm bits. Then I bought the Marathon import unit rated at 35,000 rpm. I thought it would chuck the tiny 1.6mm shank bits but does not. Only 2.35mm shank bits. So I bought a chuck designed for 2.35mm shank dental drills that will clamp the 1.6mm bits. Due to the added rotating weight of the chuck 35,000 rpm threw off-balance and basically shakes the Marathon import loose every hole. I had this happen before with a Dremel. I bought a chuck made by Dremel for a Dremel and the added rotating weight of the chuck shook the Dremel violently at 8,000+rpm. So I have concluded I need to buy a higher quality drill. Or an ultrasound unit which is a bit challenging to operate so they say. Studying EBAY's listings. CAN NOT find an electrical drill that clamps the 1.6mm super high speed bits. Beginning to wonder if I should look for a used pneumatic dental unit. They are certainly designed to hold 1.6mm bits. 400,000 rpm - grrrr. The dentist's unit was phenomenal. Plus the rush of having a 400,000 rpm tool - grrrr. Pnuematic drill heads are cheap. No idea of their life doing heavier duty though. To be honest I am anxious to receive the lightweight adaptors you referred me to. They have very little rotating weight. And this Marathon drill company makes solid aluminum high end electric drill 2.35mm units under $100 worth trying. A tool is holding me back. Can't let that happen. Can't spend to much on a tool. I bit the bullet last year and finally got rid of the Harbor Freight plasma cutter and bought a powerful/reliable $ Miller unit that makes cutting a breeze. That purchase was 15 years late. |

|

EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Mar 16, 2020 10:32:47 GMT -5

The right tool makes a job so simple, it's amazing.

I've done the same... used a sub-par tool for years before purchasing the one I should have gotten to begin with.

It's an experience that makes you want to smack yourself when you think of all the time wasted being too stubborn to just get the right equipment.

|

|

|

|

Post by knave on Mar 16, 2020 10:36:59 GMT -5

|

|

|

|

Post by mohs on Mar 16, 2020 10:40:22 GMT -5

reading this reminds why I

invented the pre-frilled hole

zip a groove

|

|

|

|

Post by rockpickerforever on Mar 16, 2020 10:47:08 GMT -5

The right tool makes a job so simple, it's amazing. I've done the same... used a sub-par tool for years before purchasing the one I should have gotten to begin with. It's an experience that makes you want to smack yourself when you think of all the time wasted being too stubborn to just get the right equipment. Doh! (Smacking forehead) I could've had a V-8!! How many times I have done that as well. |

|

|

|

Post by parfive on Mar 16, 2020 11:03:49 GMT -5

reading this reminds why I invented the pre-frilled hole     |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Mar 17, 2020 7:14:22 GMT -5

reading this reminds why I invented the pre-frilled hole zip a groove Do you find heart holes a challenge to drill Ed ? |

|

|

|

Post by rockjunquie on Mar 17, 2020 9:58:34 GMT -5

Not sure this is any help, but I use a cheap adapter for my small bits with my Foredom and it works fine. This bit is .87mm. I use high speed on metal with this. Pretty sure I got it on Amazon (US seller). |

|

|

|

Post by parfive on Mar 17, 2020 11:30:58 GMT -5

reading this reminds why I invented the pre-frilled hole zip a groove Do you find heart holes a challenge to drill Ed ? C’mon, James . . . who don’t love a frilly hole? |

|

|

|

Post by mohs on Mar 17, 2020 13:15:12 GMT -5

this is getting out of control o well... its deep ...m  slty |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Mar 18, 2020 2:38:44 GMT -5

I'm going to tell your Mom Ed lol. reading this reminds why I invented the pre-frilled hole zip a groove this is getting out of control o well... its deep ...m  slty Or perhaps my dentist he he  |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Mar 18, 2020 3:05:47 GMT -5

Not sure this is any help, but I use a cheap adapter for my small bits with my Foredom and it works fine. This bit is .87mm. I use high speed on metal with this. Pretty sure I got it on Amazon (US seller). This is similar to the adapter EricD suggested in his link Tela. I have similar on order. Cheap at about $3. May lower the vibration levels. Thanks. A few of the tiny 1.6mm shank dental burrs are drilling a 3mm thru 1/4" glass in 20 seconds with only the weight of the drill unit - 8 ounces. A ball end bit similar to what Rockoonz suggested. He has the right burr shape for the job. This easy drilling burr is fused with super sharp diamonds. They are so cheap I bought like 8 different brands and there is a wide variation of diamond sharpness(and so the required drilling force). Diamond sharpness dominates cutting rate, not diamond size so much. Especially when it comes to small diameter 1 to 3mm blunt face diamond burrs. The ball allows you to slant the hand held and drill the first section of the hole on the side of the ball where the diamonds are moving faster as opposed to the center of the blunt burr. Plus small sharp diamonds chip less in sorts. Chipping is an issue. Especially at high speeds. Never thought drilling dang holes would be such a challenge. I took this high speed Marathon drill apart. Wow, some serious accurate machine work to contain such high speed rotation. If not imported the price may be much higher due to construction. |

|