Post by TheRock on Oct 25, 2020 5:04:50 GMT -5

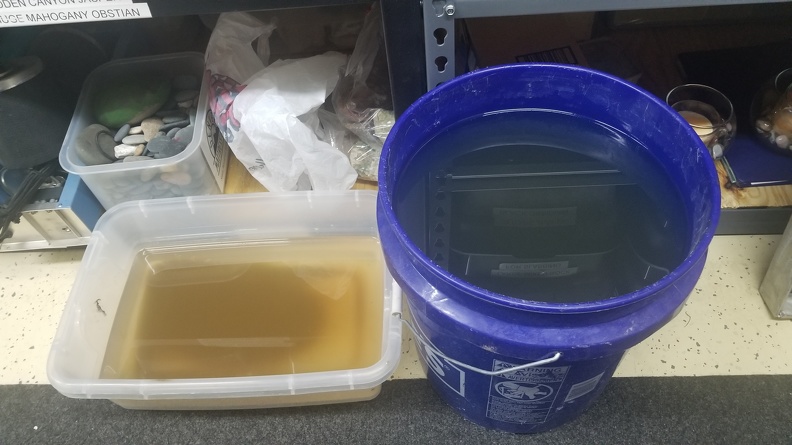

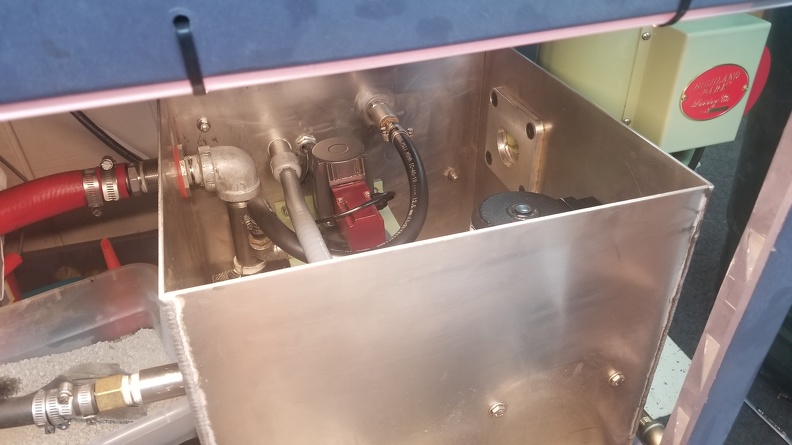

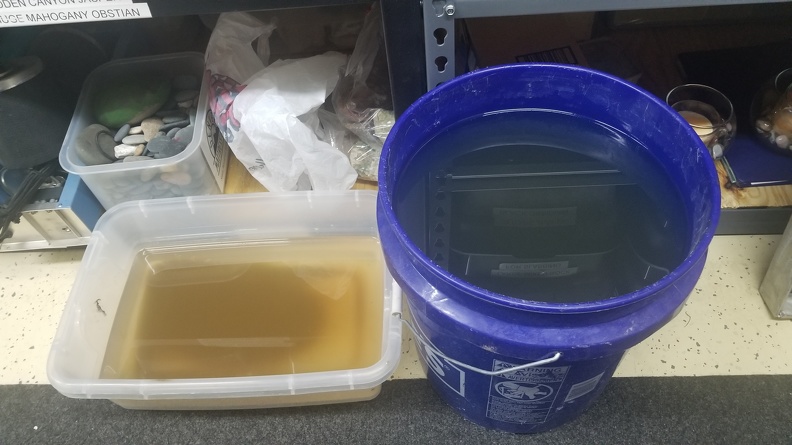

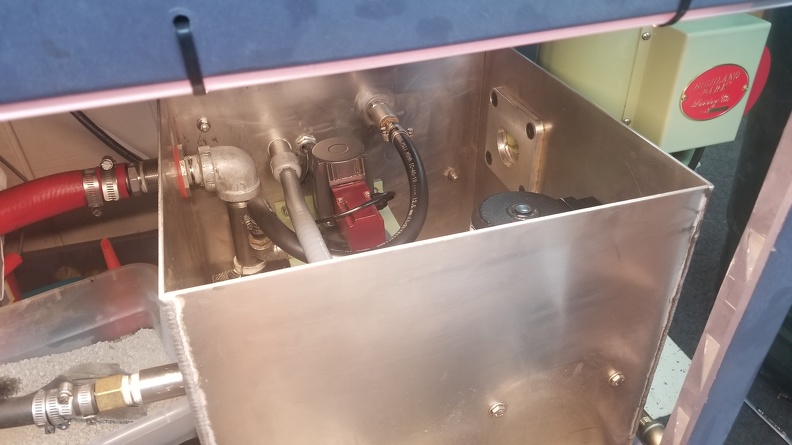

I have been giving the BD-10 Saw Quite the work out since coming home from Quartzsite in March sometime in July I heard the Dreaded Bearing noise again this was the 3rd Set of shaft bearings in the saw even with the everclean system installed which incidentally I love. I did make a Mistake when I designed and put the system together, I did not install a screen filter to protect the pumps from picking up a rock chip. At one point I had to reach down in the sump and work the pump shaft back and forth and free up the impeller from a rock chip that jammed it up. Since the saw has been in operation well over a year I pumped th oil out of the sump just over 5 gallons and gave the sump a good cleaning befor installing the new screen box. I also gave the bearing situation alot of thought. The bearings are exposed to the mineral oil and even tho the bearing has grease in it with the mineral oil slinging around it must eventually be washing the grease out of the bearing and then the rock grit even tho having smaller particulate matter it will chew a bearing up. There is and Inner and outer bearing with a cavity in between. I thought about this and wondered what would happen if I Tapped in a fitting and added tubbing to an external Zerk Grease fitting and pumped that hollow cavity full of grease and keep it full and like every 10 hours or so give it a shot of grease with a grease gun. That way the bearings will always have a somewhat preasurized and ample supply of grease to keep the bearings full of lube and the crud out. So that's what I did. I also Ordered some stainless steel screen and made two replaceable Filter screen boxes one for a spare that can be swapped out and emptied on the fly in order to keep the chips out of the pump impellers.

I also plan on adding a Hobbs Hr meter to monitor the saws hourly usage to keep up with filter cleaning greasing ect. I also thought about adding a flow switch interlock to keep the saw off in case oil ceases to flow for whatever reason to keep from burning up a blade in case of no lubrication. Here are some pics of the modifications.

I also plan on adding a Hobbs Hr meter to monitor the saws hourly usage to keep up with filter cleaning greasing ect. I also thought about adding a flow switch interlock to keep the saw off in case oil ceases to flow for whatever reason to keep from burning up a blade in case of no lubrication. Here are some pics of the modifications.