|

|

Post by TheRock on Dec 20, 2020 5:55:28 GMT -5

I have some Nevada Wonderstone that is Giving me some fits anyone have some tricks to polish this stuff? Thanks for any help! ~Duke

|

|

|

|

Post by hummingbirdstones2 on Dec 20, 2020 8:46:14 GMT -5

HIya' Duke.

You know I can't help with the tumbling, but when cabbing some pieces just won't polish as well as others. No matter what you do... .

|

|

|

|

Post by Pat on Dec 20, 2020 10:27:27 GMT -5

Shiny is good; so is matte.

|

|

RWA3006

Cave Dweller

Member since March 2009

Posts: 4,661

|

Post by RWA3006 on Dec 20, 2020 11:32:29 GMT -5

A lot of wonderstone just won't take a high polish. I made some pendants a while back that wouldn't polish so I applied a bit of carnuba wax and it looked good.

|

|

|

|

Post by stephan on Dec 20, 2020 15:49:19 GMT -5

Same experience. More often than not, matte is as good as it gets. It often has pretty patterns, though.

|

|

|

|

Post by TheRock on Dec 21, 2020 14:43:19 GMT -5

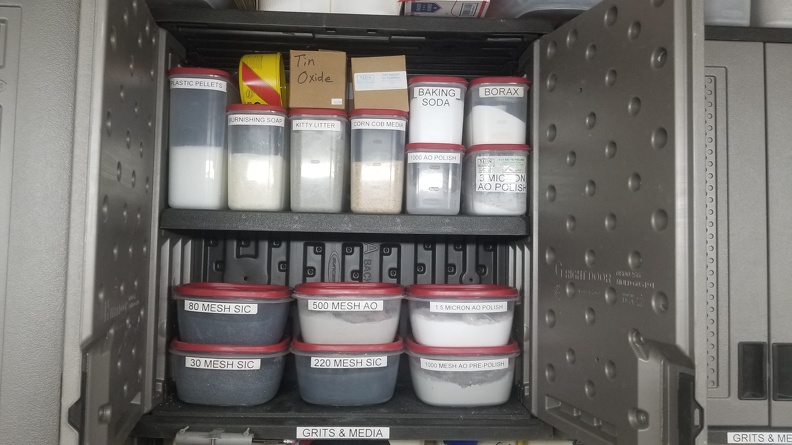

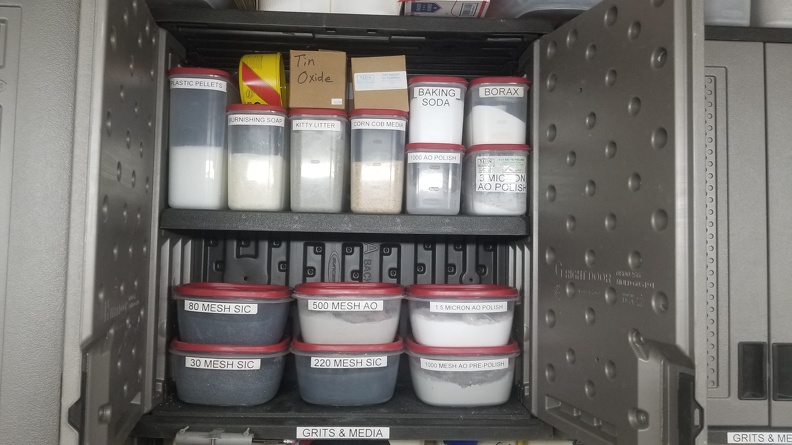

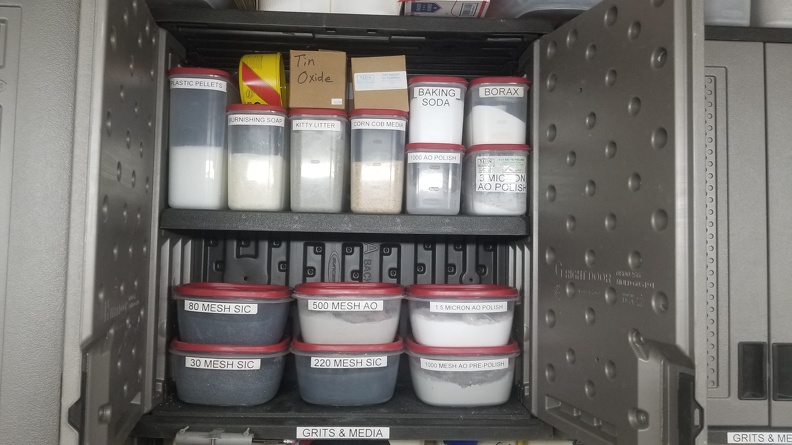

Thanks All!  Well After Running A Batch in the tumbler I polished them and yes they were Matt. I then went to MR. Cab King and made a couple Cabochons and they were Matt also. so I am currently doing this. It takes a month in the rotary to shape them I use 30 grit for my 1st stage usually 4-6 weeks then I went to 220G with borax for 5 days, Then 500G with borax for 6 days, The .3 micron polish w/ borax for 7 days if that don't do it Ill hafta make a sacrifice to the rock GOD'S. Over the summer I have tried Cerium Oxide, French Cerium Oxide, Chrome Oxide, Tin Oxide, Aluminum Oxide, IN THE FINAL POLISH STAGE...... Ive thrown about everything at it there is except WITCH HAZEL Ive even contacted MERLIN and the Great And Powerful Ozz and Ive run out of options. Ill post my results in a few diays after the 7 days in the .3 micron polish  Thanks ~Duke   |

|

|

|

Post by HankRocks on Dec 21, 2020 15:21:26 GMT -5

Thanks All!  Well After Running A Batch in the tumbler I polished them and yes they were Matt. I then went to MR. Cab King and made a couple Cabochons and they were Matt also. so I am currently doing this. It takes a month in the rotary to shape them I use 30 grit for my 1st stage usually 4-6 weeks then I went to 220G with borax for 5 days, Then 500G with borax for 6 days, The .3 micron polish w/ borax for 7 days if that don't do it Ill hafta make a sacrifice to the rock GOD'S. Over the summer I have tried Cerium Oxide, French Cerium Oxide, Chrome Oxide, Tin Oxide, Aluminum Oxide, IN THE FINAL POLISH STAGE...... Ive thrown about everything at it there is except WITCH HAZEL Ive even contacted MERLIN and the Great And Powerful Ozz and Ive run out of options. Ill post my results in a few diays after the 7 days in the .3 micron polish  Thanks ~Duke   I don't see any Paprika or Curry Powder in the cabinet!! |

|

|

|

Post by orrum on Dec 21, 2020 23:14:54 GMT -5

Duke cook the rock buried in sand in a turkey roaster as hot as it can go. Go up 50 degrees every hour and then let it cool 2-3 days so cold shock dont crack it. The colors will improve and they will sometimes get a much better polish. Merry Christmas to you, MJ and my bestest buddy Bo Bo!!! TheRock |

|

|

|

Post by TheRock on Dec 21, 2020 23:31:59 GMT -5

Thanks All!  Well After Running A Batch in the tumbler I polished them and yes they were Matt. I then went to MR. Cab King and made a couple Cabochons and they were Matt also. so I am currently doing this. It takes a month in the rotary to shape them I use 30 grit for my 1st stage usually 4-6 weeks then I went to 220G with borax for 5 days, Then 500G with borax for 6 days, The .3 micron polish w/ borax for 7 days if that don't do it Ill hafta make a sacrifice to the rock GOD'S. Over the summer I have tried Cerium Oxide, French Cerium Oxide, Chrome Oxide, Tin Oxide, Aluminum Oxide, IN THE FINAL POLISH STAGE...... Ive thrown about everything at it there is except WITCH HAZEL Ive even contacted MERLIN and the Great And Powerful Ozz and Ive run out of options. Ill post my results in a few diays after the 7 days in the .3 micron polish  Thanks ~Duke   I don't see any Paprika or Curry Powder in the cabinet!!  I needed a good one, And got it Right There! ~Duke |

|

|

|

Post by TheRock on Dec 21, 2020 23:36:32 GMT -5

Duke cook the rock buried in sand in a turkey roaster as hot as it can go. Go up 50 degrees every hour and then let it cool 2-3 days so cold shock dont crack it. The colors will improve and they will sometimes get a much better polish. Merry Christmas to you, MJ and my bestest buddy Bo Bo!!! TheRock Thanks Bill I will show my results, And if they dont give the result's I want I will do the SHAKE -N- BAKE I have a bag of baby Sand And By The Way Merry Christmas to you from me and MJ and a big hug from Bo Wevil. |

|

QuailRiver

fully equipped rock polisher

Member since May 2008

Posts: 1,640

|

Post by QuailRiver on Dec 22, 2020 0:57:37 GMT -5

I haven't done a lot of tumbling but I remember a guy I used to know who did claim that on some of the tough to polish materials that he would tumble polish them dry with cut up pieces of leather and a crushed bar of ZAM (ZAM is a mixture of aluminum oxide & chrome oxide with a wax binder). And sometimes just with plain aluminum oxide. Which makes sense to me because I have found that when polishing cabochons, aluminum oxide on slightly damp leather does a good job on some of the more tough to polish soft materials.

Larry C.

|

|

gatorflash1

spending too much on rocks

Active in Delaware Mineralogical Society, Cabchon Grinding and Polishing, 2 Thumlers B's and a UV-18

Active in Delaware Mineralogical Society, Cabchon Grinding and Polishing, 2 Thumlers B's and a UV-18

Member since October 2018

Posts: 375

|

Post by gatorflash1 on Dec 24, 2020 8:58:09 GMT -5

|

|

|

|

Post by TheRock on Dec 24, 2020 17:49:47 GMT -5

|

|

|

|

Post by TheRock on Dec 30, 2020 4:23:29 GMT -5

Well inthe oven they go tonight I'm off schedule Working on my Broken SNOW CHUCKER I Hit a Rock And Broke a Master Link While I'm At It I'm Changing Bearings I have Ordered Bearings so Last Night worked all night on it and slept all day! Guess you can do that when your retarded like me. So I will Heat the Wonderstones up like this and report back with my findings.  2:00 am 200 deg ...................... 9:30 am 525 deg 2:30 am 225 deg ...................... 10:00 am 500 deg 3:00 am 250 deg ...................... 10:30 am 475 deg 3:30 am 275 deg ...................... 11:00 am 450 deg 4:00 am 250 deg ...................... 11:30 am 425 deg 4:30 am 275 deg ...................... 12:00 pm 400 deg 5:00 am 300 deg ...................... 12:30 pm 375 deg 5:30 am 325 deg ...................... 1:00 pm 350 deg 6:00 am 350 deg ...................... 1:30 pm 325 deg 6:30 am 375 deg ...................... 2:00 pm 300 deg 7:00 am 400 deg ..................... 2:30 pm 275 deg 7:30 am 425 deg ...................... 3:00 pm 250 deg 8:00 am 450 deg ...................... 3:30 pm 225 deg 8:30 am 475 deg ...................... 4:00 pm 200 deg 9:00 am 500 deg ...................... 4:30 pm OFF 9:30 am 525 deg ...................... C O O L D O W N10:00 am 550 deg    |

|

|

|

Post by orrum on Dec 30, 2020 7:41:26 GMT -5

Cant wait to see them after the heat!!!

|

|

|

|

Post by HankRocks on Dec 30, 2020 8:01:52 GMT -5

Did you put enough Onion and Garlic in?  |

|

|

|

Post by TheRock on Jan 2, 2021 7:41:20 GMT -5

I have two batches in the Lot O will give my results Im gonna give them at least 5 days in POLISH.  ~Duke |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,616

Member is Online

|

Post by jamesp on Jan 2, 2021 9:40:11 GMT -5

If heat treated it will be softer. It changes color well, beautiful after. and before... I got some New Mexico material and it was well silicified and polished easy. Shaped slow. Got some Montana material and it would only take a nice matte, after cooking it it took a low matte polish. Both shaped quickly. The purple material is Montana and heat treated. The yellowish is from New Mexico and easily polished. Matte or polish who cares, the stone is stunning either way. Yours look awesome. www.flickr.com/photos/67205364@N06/sets/72157649620386342The Montana is at center, the New Mexico is at right. Both in rotary same amount of time but look at how well rounded the softer Montana shaped compared to N.M. rock especially after the Montana was made softer by cooking. I took it to 600F, seemed a good stopping point. Result solid and friendly to knapp.  PS I ran a few of these with glass several times in finish stages in vibe. Glass came out with brilliant polish, Montana rhyolite came out with same damn matte finish go figure. Swinging white flag. |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,616

Member is Online

|

Post by jamesp on Jan 2, 2021 10:11:34 GMT -5

I went 100F every 4 to 6 hours, held at 600 for 4 hours and cooled it at the same conservative 5hours/100F rate.

Standard 600f/3 day cook used on coral.

Coral will crack if you cool it fast, not rhylolite because of it's grainy structure. Coral is glassy.

Good to see you becoming a rock chef Bob. Rhyolite is a great target to cook.

Coral is submerged in water in most cases. Best to heat it for a couple of days at say 200F(BELOW 212F) to dry it out.

Lest you like rocks exploding in your cooker. Water breaching 212F boils and has a real bad way of exploding you rocks.

If you reduce them to tumble size before cooking instead of cooking 5 pounders you will greatly reduce the chance of rocks blowing up AND get better color.

It like most rocks does much differently if you break it up into tumble sizes before cooking as opposed to cooking chunks and the breaking them up. The first ~1/8 inch of depth normally has a richer cooked color, tumbling the edges off exposes both the inside color and the skin color.

|

|

|

|

Post by TheRock on Jan 13, 2021 18:56:33 GMT -5

|

|