|

|

Post by MrP on Oct 17, 2017 4:17:16 GMT -5

I have no clue of the consistency of vibra dry but as you were talking about it I started thinking of floor sweeping compound. The compound is just sawdust with a lite floor oil in it. It sure seems like that type of consistency would help cushion the stones. I am not sure if sawdust alone, as the medium, would work but it may be worth a try..................MrP

|

|

|

|

Post by MrP on Oct 15, 2017 10:41:34 GMT -5

I thought I would show you what happened and how I fixed my UV-18 bowl. Very soon after I got my UV-18 I put to large of a rock into it for the 1st stage. Having used a Lot-O for years I found that if it fit through the top of the Lot-O you could work with it. Course grit can be used in a Lot-O as well because it is a rubber barrel/bowl. By mistake I put course grit in the UV-18 and thought what the heck, can't hurt for one run. Well that was the run I put an oversize rock in. I watched and made sure the rock would roll around without any problem, it did, until I put the cover on! For some reason I didn't check it for 24 hours. Of course when I took the lid off everything started moving, because it was caught between the lid and bottom. I was happy to see everything moving and thought wow I sure can tumble big rocks in this one. Imagine my disappointment when I cleaned the bowl and found the divot in the bottom. When I held it up to light I could see light through the divot.

To repair I tried to super glue a piece of plastic I shaped to fill the divot. The glue stayed but the plastic would not. I ended up just using superglue to fill the divot and it held so that is when I decided to coat the entire bowl with superglue. As you can see the bowl has worn thin. I just use it for polish now. I will also tell you that when a UV-45 gets to this stage it cannot be used because the weight of the rocks makes it sag!

Light showing through bowl after about 4-5 years use.

Close up. The spot where the patch is was almost that thin 4-5 years ago when the mistake/divot was made.

Worked/works for me. Good Luck..........................MrP

|

|

|

|

Post by MrP on Oct 15, 2017 9:54:33 GMT -5

I don't understand. How does the plastic sloughing effect the finish of the stones in any way at all? Isn't it simply a visible component of the slurry? @shotgunner Plastic sloughing off has no effect on finish. By the time you get to polish there is almost no abrasion on the barrel/bowl. I use the superglue to extend the life of the barrel/bowl...................................MrP |

|

|

|

Post by MrP on Oct 15, 2017 7:05:15 GMT -5

I have had that with a couple of my bowls but not anymore. I coat my bowls with thin superglue. In one of my first loads in the UV-18 I put to large of a rock in and it got caught and wore a thin spot in the bowl. Made me sick! I wasn't sure what to do but knew I had to do something so I tried to glue a piece of plastic into the spot. The plastic did not hold but the superglue looked good so I built up layers over time. Used the bowl for 3 years 24/7 for 220 sic grind. Over time I saw the whole bowl was wearing thin so decided to put superglue in the whole bowl. Do it outside because that much superglue gives off a lot of fumes. The bowl is still used for polish. I have coated all of my bowls...................................MrP Good advice MrP! Any particular super glue... or does it matter? Use a paint brush to apply it? gmitch067 Not sure it matters much for that. I found a large bottle of Hobbylinc super thin for a good price so that is what I used for coating the bowls. Just pour a bunch in and swirl it around until it is all coated. All it ends up being is a thin layer but it seems to last a long time. I only repeat for the barrels/bowls I use for Medium Sec grinding because Sic grit is sharp and stays sharp until very fine. Remember to do this where there is a lot of ventilation!

I don't know of anybody else doing this but superglue is a lot cheaper then new bowls and it has worked for me. Good Luck.........................MrP

|

|

|

|

Post by MrP on Oct 14, 2017 18:47:47 GMT -5

Do you know what region/ mine the picture jaspers is from? I have 1 piece as matte as yours that I got in a mix a while back, but the 2lbs of picture jaspers I got from rocktumbler, took a very good shine. I need to take photos of those and post. Your picture with black shavings, mind are not anywhere near that. I wonder why your bowl is doing this? I do not know where these were mined... sorry. When I started the hobby back in January 2017 I bought many pounds of rocks from Amazon... I actually lost track of which mining company supplied them. Many times I bought the same rocks twice because they were being sold under different names! I wasted a lot of $ on poor choices. I think these Picture Jaspers might have been one of those purchases. (Sometimes I learn the hard way! ... but I hope I still learn!) I have since started buying from more reliable sources - Like The Rock Shed. I only started this load out with 1-2 pounds of Picture Jaspers... Which leads me to believe these came from Amazon, because I usually buy in 5 pound batches from The Rock Shed. All my UltraVibe bowls throw off black shavings (2 UV-10, and 2 UV-18). It is more noticeable in the "Polish Only" bowls because of the contrasting colors, but even in the regular grit bowls I notice shavings on the ceramics in the wash water. I have had that with a couple of my bowls but not anymore. I coat my bowls with thin superglue. In one of my first loads in the UV-18 I put to large of a rock in and it got caught and wore a thin spot in the bowl. Made me sick! I wasn't sure what to do but knew I had to do something so I tried to glue a piece of plastic into the spot. The plastic did not hold but the superglue looked good so I built up layers over time. Used the bowl for 3 years 24/7 for 220 sic grind. Over time I saw the whole bowl was wearing thin so decided to put superglue in the whole bowl. Do it outside because that much superglue gives off a lot of fumes. The bowl is still used for polish. I have coated all of my bowls...................................MrP |

|

|

|

Post by MrP on Oct 14, 2017 10:16:31 GMT -5

James Yes I either do them in the Lot-O's or UV 4/10, it just depends how I feel at the time. Truth be told I have been doing very little tumbling or cutting for some time because I retired in July. I always knew when I retired I would spend a large amount of doing nothing but playing with my rocks. How wrong can a person be!!! I have spent my time doing things around the place that have needed to be done plus getting things out of the way for the future. Winter is coming so will bring the tumblers into the basement. A pain in the a$$ for cleanout but it is what it is. I have a 10" Lortone Saw that I use Lube Kool in so I can cut smaller stuff in the winter also.

I like your idea. It being an open pipe to start with you can weld the dividers in from the open before you weld the end on. The only reason I say 1/4 is because I run my tubs very full, well over the halfway point. The deeper the fill the larger the slab I can run............................MrP

We are at that age. Man, I see my friends retiring and never see them anymore. What's w/that ? Years of honey do's rain down out of the sky. Years of you-wanna-do's rain down from the sky. Congrats and enjoy, stay off that couch !! Michael, I was going to buy 2 or 3 of those little black 4 pound rubber hoppers used with the Vibrasonic and set them down in the half pipe. Weld hooks to strap them in. They have a round bottom and should sit snuggly in the 1/2 pipe. That way I can remove the hoppers individually. Now I get where you are going with this build...................................MrP |

|

|

|

Post by MrP on Oct 14, 2017 8:49:05 GMT -5

MrP I was going to split the pipe in half and put 2 or 3 independent H-4# hoppers into the half pipe. In an attempt to prevent all the big rocks and thick slurry from migrating to one end. Having a lot of problems with this migration at low off-balance settings. So you are doing your small stuff in the Lot-O's ? Like this rig Michael:  I James Yes I either do them in the Lot-O's or UV 4/10, it just depends how I feel at the time. Truth be told I have been doing very little tumbling or cutting for some time because I retired in July. I always knew when I retired I would spend a large amount of doing nothing but playing with my rocks. How wrong can a person be!!! I have spent my time doing things around the place that have needed to be done plus getting things out of the way for the future. Winter is coming so will bring the tumblers into the basement. A pain in the a$$ for cleanout but it is what it is. I have a 10" Lortone Saw that I use Lube Kool in so I can cut smaller stuff in the winter also.

I like your idea. It being an open pipe to start with you can weld the dividers in from the open before you weld the end on. The only reason I say 1/4 is because I run my tubs very full, well over the halfway point. The deeper the fill the larger the slab I can run............................MrP

|

|

|

|

Post by MrP on Oct 14, 2017 7:09:48 GMT -5

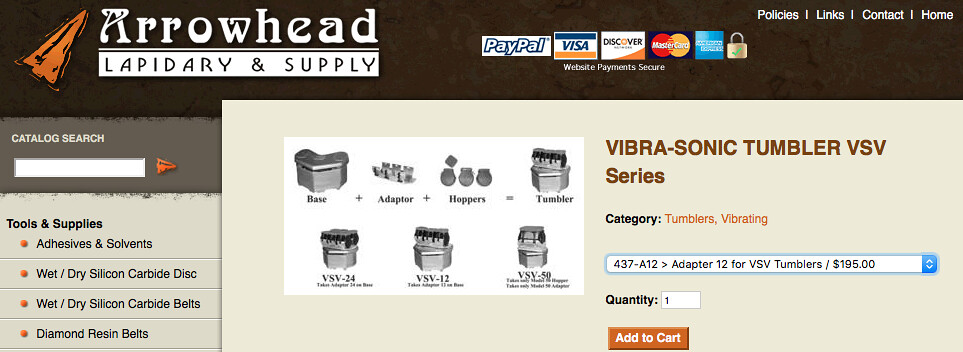

jamesp, what number do you have your weights set on? Did you decrease it from a regular agate tumble? jamesp the way your slurry travels to the right, is it level? I would think that over time the liquid would migrate if when slightly off. This Vibrasonic has a cylindrical hopper unlike a donut or a vertical hopper like the Lot-O. It has an adjustable counterbalance on the left side and the right side. If there is a slight difference in the counterbalance then the vibration will send small rocks to the say left and big rocks to the right. Same with a thicker slurry, the thick goes to one side and the watery slurry goes to the other. This phenom is much worse at gentle settings. Well, your goose is cooked if the big rocks all separate from the small rocks and beat themselves up. Or the protective slurry all goes to one side and you have no protection on that side. I did install a divider to circumvent some of this problem. It's miracle this obsidian is not totally bruised given the conditions. one reason I do a big rock on each side of the divider is because I can put all small rocks in with one big rock. that eliminated the size division issue, all smalls and one big in each compartment. or tumble all Mohs 7 rocks that simply do not bruise. fantastic5 , you can tilt that thing like a ski slope and the vibrations still continue to separate big from small, thick from thin slurry. I have tried it all. and making more counterbalance on one side than the other. Putting a soft foam mat under one side helped. The 35 pound hopper is shaped like a Lot-O hopper. It is narrow and tall. It is said that it mixes much better. colliel82 , for agate I had the weights set at 1.2 on one side, 1.3 on the other. Gave a vigorous action. Must have run 25-30 loads of agate-wood-jasper successfully at that setting. And could run thinner slurry which did not have separation issues. In the past and for this run I dropped the counter weights to .9 an 1.0. Much smoother action but the separation issues way increased. Since then I installed a divider which has allowed me a successful run so far. But still suffering from separation within each compartment. A third divider would help the rock size separation, but the thicker slurry still slips by the dividers. dividers not 100% sealed separate. Probably the best thing I could do is mount two or three 4 pound Vibrasonic hoppers on the deck of the base unit. They are vertical hoppers and are supposed to have excellent mixing. I like the idea of having 2 to 3 separate hoppers and the ability to run separate loads. Check this out, perfect, 6 four pound hoppers. 2 or 3 four pound hoppers would be plenty. Just now found them on Google images, hmmm. I may purchase such. Never seen them, called VSV. Aftermarket ? These would solve my separation issues by George. A 6 pack, good greif(unlike me ha ha);  Or a 3 pack, less than $200. Never seen these. I'd just run two. This would be perfect. Bet I'm going to purchase this.:  Or a 2 pack, the old style:  My VT came with the 2 pack but I have 2 Lot-O so I put a large tub on it so I could polish large slabs......................MrP |

|

|

|

Post by MrP on Oct 14, 2017 7:04:28 GMT -5

MrP Looks like aftermarket hoppers. Up to a 50 pound single. Those hoppers have a round bottom, could saw a pipe in half lengthwise...weld base plate on.  There you go. I have run many loads with 60/90 Sic in my LP tank barrel with no liner. I just had a leak show up, and when I checked it is where I welded it to the bar that I use to bolt it to the vibe. I am sure you are a better welder then me so you would not have that problem! If you use a pipe you will have many years of use and if you are using AO I doubt you would ever wear it out. I would only cut about 1/4 of the top part of the pipe, full length, then you can make straps to hold the top on. Cut a piece of inner tube to seal the top so you can control the moisture.....................................MrP |

|

|

|

Post by MrP on Oct 11, 2017 12:13:43 GMT -5

when I rotary tumbled I did SiC 46 SiC 220 AO 500 AO 14,000. 8-10 days for 220 and 500, 10 to 14 days aO 14,000. I used sugar for a slurry thickener in 500 and 14,000. 3 cups for 16 pounds of rock, 75 to 80% full. About always Mohs 7 agate wood and coral. Did so many loads, blindfolded. Over and over, same recipe. 4 - 16 pound 6" barrels at ~30 RPM Bought a vibe, better than a 30 year old wife. What are you doing? Leaning on that Vibe?..........................MrP |

|

|

|

Post by MrP on Oct 11, 2017 9:15:41 GMT -5

Thank you both. That picture is exactly what I wanted. Probably take a look and try to do a modify next time I get down time on the vibe. Of course that means I have one more thing to learn how to play with to get nice shinies. fish, my Vibrasonic will polish the heck out of Mohs 7 rocks. But softer rocks like obsidian and rhyolite either frosts or only achieves a matte polish. It will do much better if I tumble smaller soft rocks. Larger soft rocks almost frost. The frosting on soft rocks is about proportional to their size. The frosting is worse with increased soft rock size. The matte finish is duller with increased soft rock size. No rocket science there, the bigger rocks hit each other harder in vibratory movement. By the same token, two one pound Mohs 7 rocks in the vibe will frost due to hitting each other. Run only one big rock and there is no frosting. No matter how much or what type of padding or media I have tried, the two big rocks find and damage each other. Mind you, the Vibrasonic has an adjustable counterweight and I have not played with reducing the off balance too much. It appears the manufacturers have designed the vibes for agate and Mohs 7 hardness rocks for the most part.

MrP does any of this make sense to you ? Yes....................................MrP |

|

|

|

Post by MrP on Oct 11, 2017 9:14:08 GMT -5

MrP It looks like you added the bolt to reduce counterbalance on UV 10 and UV 18. To smooth action for polish, correct ? If so, does your UV 10/18 still have adequate movement of the rocks when softening the vibration ? Am interested in your motives, curious minds. Mainly because polish seems hard to achieve if vibration is overly violent, especially on softer rocks.

jamesp Motive? Because it was betting the hell out of obsidian and others. If set right it really smooth's the action and still does a good job on polish.................MrP

|

|

|

|

Post by MrP on Oct 11, 2017 4:27:53 GMT -5

MrP I know you run a larger hopper on your Vibrasonic. Apparently it will run a 35 pound hopper. I believe that you are supposed to increase the counterweight to run the 35 pound hopper. Did you increase you counterweight for the steel hopper you fabricated ? So playing devil's advocate I thought I may add weight to my 14 pound hopper in an attempt to reduce the vibration to a very fine low amplitude buzz. Adjusting the counterweights too. Or maybe just adjusting the counterweight to minimum counterweight. All in attempt to avoid bruising soft stones. I wish I had an extra Vibrasonic. I would like to put larger sheaves on the motor to increase the counterweight shaft from about 3000 RPM to about 4500 RPM. Then reduce the counterweight. To achieve higher vibration speed with less amplitude. In other words a very high speed vibration rate with a slight movement distance(amplitude). Closer to ultrasound. Closer but no where near anyway. Is this what the counterweight looks like on a Thumler's UV vibe ?  jamesp fishnpinball Yes that is the counter weight on the UV-18. That one is thick enough to tap for a 1/4" bolt. The counter weight on the UV-10 is only 1/4" thick so it has to be tapped for a smaller screw. All that is happening is putting more weight on the lite side to help smooth out the vibrations. The UV-45 has a weight that looks like that but has a hole on the heavy side with a bolt and extra washers added to it. I just remove some of the washers to settle it down some. For the 'Rough' stage I have no problem with leaving it the way it came but I think it is a little aggressive for polish.

As far as the Viking I am always adjusting the weights depending on the tub I have on and what I have it doing. 100% out of balance really makes things move...........MrP

UV-10

UV-18

UV-45

ETA pictures

|

|

|

|

Post by MrP on Oct 10, 2017 18:32:55 GMT -5

I have some bruising on obsidian too. Especially if the pieces are golf ball/ping pong ball size. Some vibes have adjustments on them. Which one do you have ? I believe it is the amplitude. I would be nervous about constraining the amplitude of the vibration mechanically as it may heat up the motor. I think the best way is by reducing the off-balance if possible. I did have a good up date using the pumice. I did a clean out and started with fresh pumice. Cleaned all AO polish off. After 3 hours the pumice polish on the obsidian is starting to dissappear. The reason that is good is that the ~80 grit pumice is removing a layer. It is resurfacing the obsidian. Eventually the pumice needs to start breaking down. It is defined as friable. I hope it breaks down fairly quickly. It could be that in 6 hours it is still removing more luster/polish. Or 12 or 24 hours. No knowledge of break down rate. Hopefully not too fast as it would be best if it removed a layer of the stone. Then break down to a super nice polish compound and lay a fine polish down. Hard highly polished Mohs 7 coral media is running with it. The coral lost no polish after 3 hours like the obsidian did. And it shouldn't. The coral is harder than the pumice. I will pull coral and obsidian at 6 and 9 hours. Check on it's finish. I have a UV-10. I agree with you that the only way to adjust the amplitude would be to changed the position of the weight, but I am not aware that you can do that on the UV-10 without making some type of modification. I am not afraid of modifications if they are done in a proper fashion. Though having the proper tooling might be an issue. There are lots of machine shops around though. If I can describe what I want done and it is not ridiculous price wise. I also have tumbled a little bit of quartz that I found near the local river. (Rare in this part of Ks) it bruised very badly which surprised me. Probably has something to do with how far it had to come downriver. getting hammered all that journey. And keeping us in the loop is awesome. Looking forward to updates. Drill and tap the short side of the weight for a 12-2 bolt then you can change the counter weight by changing the bolt length and amount of washers and nuts. Good luck............MrP |

|

|

|

Post by MrP on Oct 7, 2017 19:24:42 GMT -5

The day I lost my gun.  A LOT of years ago (notice short hair!)  Looks like calm water?  ??...................................MrP |

|

|

|

Post by MrP on Oct 7, 2017 16:31:07 GMT -5

Here is a picture of my lost gun  *sniffle*  A thigh holster? uh... no. I just ordered another holster and a couple mag holders today for a gun class I have in Nov. Needed gear for off side carry. Here is the website for high quality Kydex holsters and spare mag holders: dalefrickeholsters.com/Someone here makes Kydex holsters, forget who. Maybe a search will find 'em. If it isn't too painful I a thinking we need to hear the story...................................MrP |

|

|

|

Post by MrP on Oct 7, 2017 16:20:06 GMT -5

$50.....................................MrP

|

|

|

|

Post by MrP on Oct 6, 2017 6:08:10 GMT -5

I am not sure I have. If I find a good deal I buy. Tumblers 1-UV10 with bowl for 4, 2-UV18, 1-UV45, 2-Lot-O, 1- 3Lb rotary, 1-QT66 with extra 12Lb barrels, 1-Viking VT45 that also has the 4Lb tubs, 1-Rockette Vibratory finisher 800, which I still have to get running, 1-3 tier rotary I built that I run a combination of 12, 15, and 60Lb barrels on.

Every tumbler acts a different way so it kind of depends what I am doing as to which one I use...................................MrP

And a concrete truck parked in the driveway for stage 1 to keep all those vibes running . I wish! Years ago I passed on one that could tumble about 20 gallons at a time. Stupid, stupid..................................MrP |

|

|

|

Post by MrP on Oct 6, 2017 6:03:34 GMT -5

I am not sure I have. If I find a good deal I buy. Tumblers 1-UV10 with bowl for 4, 2-UV18, 1-UV45, 2-Lot-O, 1- 3Lb rotary, 1-QT66 with extra 12Lb barrels, 1-Viking VT45 that also has the 4Lb tubs, 1-Rockette Vibratory finisher 800, which I still have to get running, 1-3 tier rotary I built that I run a combination of 12, 15, and 60Lb barrels on.

Every tumbler acts a different way so it kind of depends what I am doing as to which one I use...................................MrP

Wow... It would be really interesting to find out what you when you specifically select different vibes for stones and why. It really depends more on the amount and size of what I am tumbling. I cut many slabs and will just throw many in as a slab.

With my UV vibe tumblers I have the weight counter drilled and tapped so I can adjust the movement of the material in the bowl. If I am using 180 AO I will decrease the counter weight to make it more aggressive but add weight to settle it down for finial polish. I also use a large percentage of smalls, 90% or more, (ceramic or trimmings and scraps) for the 180 AO stage then go to the same aquarium quartz rock that ingawh uses for polish.

Most of the rotaries have sic in them because I don't do much finish work in them.

The one thing I disagree with others on is how often a vibe needs to be checked. If you get things right they can run for days with out looking if you get things right! That is getting the polish, psyllium, dreft, and water right.

Good Luck

MrP

|

|

|

|

Post by MrP on Oct 5, 2017 9:45:35 GMT -5

I have both 4 and 10lb bowls. Same base.....................................MrP That's what I thought. Why did you decide on those 2 sizes? I am not sure I have. If I find a good deal I buy. Tumblers 1-UV10 with bowl for 4, 2-UV18, 1-UV45, 2-Lot-O, 1- 3Lb rotary, 1-QT66 with extra 12Lb barrels, 1-Viking VT45 that also has the 4Lb tubs, 1-Rockette Vibratory finisher 800, which I still have to get running, 1-3 tier rotary I built that I run a combination of 12, 15, and 60Lb barrels on.

Every tumbler acts a different way so it kind of depends what I am doing as to which one I use...................................MrP

|

|