|

|

Post by BuiltonRock on Jan 24, 2008 14:07:22 GMT -5

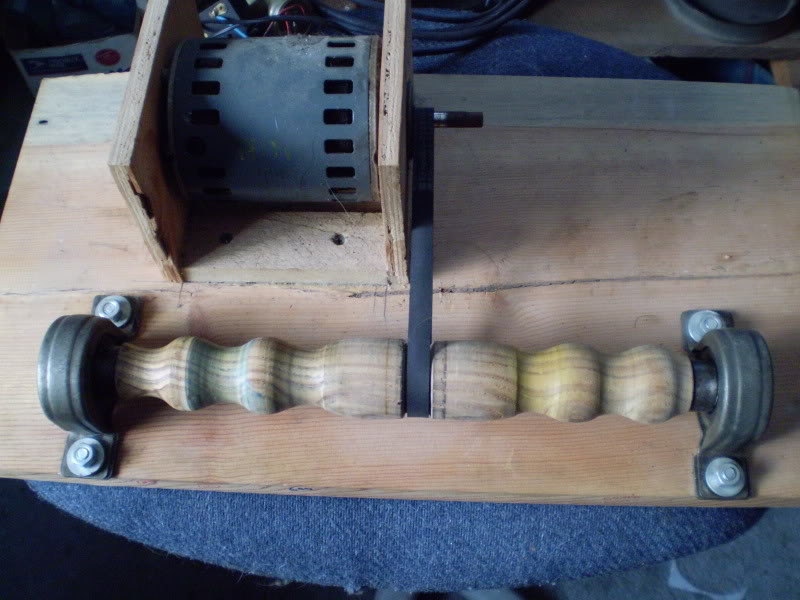

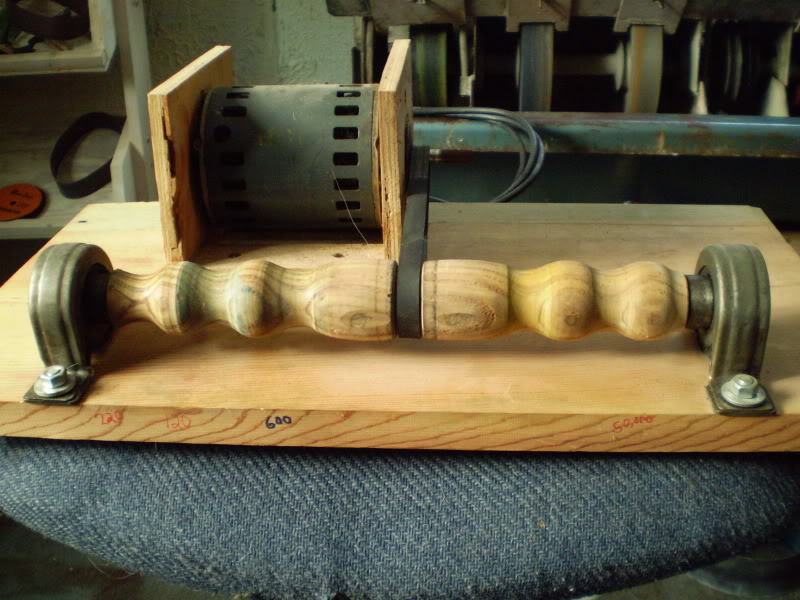

Tonyterner made me a wooded lap on his lathe to my specifications as an experiment. Here are the results.    I usually have a hard time getting a good shine on softer stones such as Sodalite, this Sodalite cab was shaped on an 80 grit diamond wheel and then I used a 220 grit SIC belt, 400grit SIC belt and finally a 600 grit SIC belt and was finished on the wood lap alone, which has a 14K diamond paste section, 50K and 100K. These were the pastes I had, if I was doing it again and I will, then maybe 8K, 14K and 50K would be better.  I did use a little extender fluid.  I had this old bench grinder and it turns fast at 3450 RPM. We made the diameter small to keep the surface speed down, but I think anywhere from 2000 to 3000 rpm would work. He is willing to make these for us RTh'ers. He will say for free, but we should cover his cost and time. I think he did a good job and that is the best finish I have ever gotten on Sodalite. I will let him answer any questions about the wood. john 7/20/2017 ADMINISTRATIVE EDIT: Repaired broken PhotoBucket images |

|

dshalldms

starting to spend too much on rocks

Member since January 2008

Posts: 113

|

Post by dshalldms on Feb 1, 2008 4:56:17 GMT -5

Hi John, Very nice work. It,s a technique I intend to use myself, although it's not mine! Daniel Lopacki gives a detailed discription at... lopacki.com/tips/ I think the recycling of old equipment for lapidary uses would tempt many of use old timers back into the hobby. Keep up the good work, Derek Hall |

|

|

|

Post by BuiltonRock on Feb 1, 2008 8:45:27 GMT -5

Thanks Derek,

I should give credit to Lopacki and Graves. I used their ideas and information to arrive at what would work for me! Also a thanks goes to Tony W. and Tonyterner.

john

|

|

dshalldms

starting to spend too much on rocks

Member since January 2008

Posts: 113

|

Post by dshalldms on Feb 1, 2008 14:10:19 GMT -5

|

|

|

|

Post by BuiltonRock on Feb 2, 2008 0:45:21 GMT -5

Derek,

Amazing how simple things can really be!

john

|

|

notpetrified

off to a rocking start

Member since February 2008

Posts: 14

|

Post by notpetrified on Feb 9, 2008 15:38:29 GMT -5

Thanks for the great idea. I have a little grinder in the yard that didn't sell at a yard sale. I'm taking the grinding wheels off and replacing them with cloth wheels.

|

|

Rockygibraltar

fully equipped rock polisher

Member since February 2006

Posts: 1,404

|

Post by Rockygibraltar on Feb 12, 2008 21:41:05 GMT -5

The proof is in the product. Thats a beautifull cab you've made.

|

|

dshalldms

starting to spend too much on rocks

Member since January 2008

Posts: 113

|

Post by dshalldms on Feb 13, 2008 5:00:22 GMT -5

Hi John,

Just a short question...

Do you use this unit wet or dry?

Derek

|

|

|

|

Post by BuiltonRock on Feb 13, 2008 14:12:18 GMT -5

Derek,

I used a little WD-40 as an extender fluid. Next to no heat is generated as there is hardly any surface contact area.

john

|

|

|

|

Post by BuiltonRock on Feb 23, 2008 6:08:59 GMT -5

|

|

|

|

Post by sandsman1 on Feb 23, 2008 11:44:16 GMT -5

hey john grab a spray can of silicon spray and use that for the diamond paste thats what i use in my leather buff belt and it stops drag and helps sread the diamond paste -- alot easyer to just spray coat the belts for me and cheaper then extender fluid they sell

|

|

|

|

Post by Jack ( Yorkshire) on May 22, 2008 2:59:52 GMT -5

Hi Lowkey,

Bumped this one up for you,

Jack

yorkshire uk

|

|

UtahRockHound

spending too much on rocks

Sometimes your the Windshield, sometimes your the Rock.

Sometimes your the Windshield, sometimes your the Rock.

Member since May 2008

Posts: 301

|

Post by UtahRockHound on May 22, 2008 11:49:38 GMT -5

Trying to keep on topic, and not side track, I have a question here.

Making home made tools is second nature for me. Polishing stones on the other hand is a new adventure for me. I am only just learning different methods.

This would be easy enough to do, but the question is how affective is this. In other words, I have read several times how great diamond dust works when used with wood or leather, but no one mentions how fast or easy it is compared to other methods.

The main reason I ask is, I currently use Chrome Oxide on a slow turning pad for my final polish. I love the results, but the mess and stains in the stone are hard to deal with. I am looking for a better way. I was thinking of putting a leather pad with diamond on it or tin oxide or something.

|

|

|

|

Post by akansan on May 23, 2008 10:18:18 GMT -5

The difference with diamond versus Chrome Oxide is that you have to take diamond through the steps. The oxide polishes are generally one step in and of themselves. From the 600, I go to 1200 --> 3k --> 8k --> 14k --> 50k. I don't know how long it takes you to put a polish on a stone using Chrome Oxide, but I spend about 1 minute give or take a bit at each of these steps. The last two steps are much shorter. And if I had to trade out belts, it would take longer. Hope this helps.

|

|

|

|

Post by Jack ( Yorkshire) on Dec 15, 2008 8:37:32 GMT -5

Bumped up for Sparkles,

Jack

Yorkshire UK

|

|

mirkaba

spending too much on rocks

Member since August 2006

Posts: 321

|

Post by mirkaba on Dec 15, 2008 13:21:33 GMT -5

Hey John...........Glad to see this thread bumped! (Thanks Jack) I had a friend turn this one down and it is actually made from a baseball bat. I use it for opals but have tried agate and even finished a small saphire cab on it. It turns a little slower (about 650 rpm) but really does a bang up job on the opal. It is driven by a vacuum cleaner belt and has grits from 120 to 50,000. Everything even the pillow blocks are 'used'. I have since had a 3" dia. spool turned for polishing larger stones but still have not put it together......Thanks Bob   Admin Edit: fixed photos - original code below [img src="http://i155.photobucket.com/albums/s287/mirkaba/PC150142.jpg"]

[img src="http://i155.photobucket.com/albums/s287/mirkaba/PC150143.jpg"] |

|

|

|

Post by BuiltonRock on Dec 15, 2008 14:42:01 GMT -5

Since I moved this summer I have not set this back up, but I should have got it out for some soft Rhodocrosite I cabbed yesterday.

Wood and diamond paste works wonders on softer stones.

John

|

|

|

|

Post by Jack ( Yorkshire) on Jan 31, 2009 1:44:00 GMT -5

Hi Mircaba,

Or any one else !

Can you tell me what sort of wood a Base ball bat is made of

I found a cheap source of larger 2" Beach rolling pins in a household shop , would that be a good wood to use for this Polishing Bat ?

Jack

Yorkshire UK

|

|

mirkaba

spending too much on rocks

Member since August 2006

Posts: 321

|

Post by mirkaba on Jan 31, 2009 8:23:19 GMT -5

It should be OK. Mine is made from ash. I think soft woods work well also. They may even hold the diamond better. Bob

|

|

|

|

Post by mohs on Jan 31, 2009 16:27:27 GMT -5

That's great ideas! I'm working on making a v shape wood wheel to polish inside the web of hearts.

|

|