|

|

Post by Bejewelme on Feb 14, 2010 12:19:26 GMT -5

Adrian:

No wonder you are so busy holy crap that is a project, very cool, I know it will be stunner when finished! You are so creative!

Amber

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Feb 20, 2010 0:29:49 GMT -5

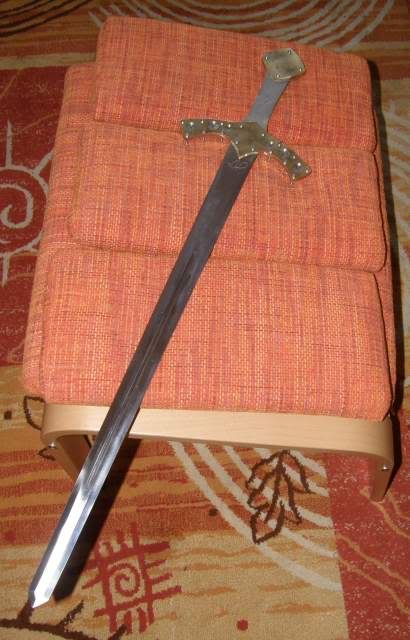

Hello, again! These days I made some more metal work. Firstly, I brought the blade to its final shape, including the chamfers of the edges on both sides. To make the chamfers look straight, I built a device to keep the filing angle constant. I found the idea on a web-site which Tom-Connrock shared with me - thank you Tom for sharing your knowledges and experience.   Then I smooth finished the blade, but didn't polish it yet. Hopefully I will be able to do it, it is much more difficult than it seems.  I also started the works at the guard and handle brass scales     And that's how the sword looks now:   Thanks for looking, Adrian |

|

spokanetim

has rocks in the head

Member since October 2009

Posts: 656

|

Post by spokanetim on Feb 20, 2010 1:32:04 GMT -5

Wow! That's really amazing to see you work this out. Really impressed, it's going to be a work of art for sure!

|

|

SteveHolmes

fully equipped rock polisher

Member since July 2009

Posts: 1,900

|

Post by SteveHolmes on Feb 20, 2010 10:31:30 GMT -5

Adrian,

Your a Genius my friend! That is so flippin' cool. The contraption you made so you could file it evenly just shows your ingenuity. It looking fabulous and I'm keeping my sights on this thread to see the finished project. When you want to do something you go in with both feet running and don't stop until it's completed.

Steve

|

|

|

|

Post by rockrookie on Feb 20, 2010 22:56:03 GMT -5

WOW !! Adrian .

that is too cool !!!

you are extremely talented !

--paul

|

|

|

|

Post by Toad on Feb 21, 2010 10:15:28 GMT -5

That is looking great. You should be an engineer. Are you one?

|

|

agatemaggot

Cave Dweller

Member since August 2006

Posts: 2,195

|

Post by agatemaggot on Feb 21, 2010 12:20:43 GMT -5

Adrian,

I liked the method you used to cut the stainless Steel blank. Not many guy's I know would have thought to use a Skill type saw with an abrasive blade to get the job done. Stainless is one of the most difficult metals there is to work with, hard to cut, drill or grind. I like your attitude, (it ain't what ya need, it's what ya do with what ya GOT) !

Thank you for letting us watch over your shoulder while your project takes form !

Harley

|

|

|

|

Post by rockmanken on Feb 21, 2010 12:47:17 GMT -5

Now it is really taking shape. You have more patience than I have. It is looking fantastic.

Question: whatcha gonna do with the screws and nuts. Weld it and then remove them?

Ken

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Feb 21, 2010 14:10:31 GMT -5

Thank you friends.

Steve as I told before this filing device it is not my idea. I'd like to say I imagined it, but I didn't

Toad, yes I am one of them.

Ken, the bolts&nuts will stay there only during the work, then I will replace them with brass rivets.

Adrian

|

|

|

|

Post by frane on Feb 22, 2010 9:19:45 GMT -5

Even with all the step by step pictures, I still can't say that I would ever be able to "create" the tools needed to make a work of art like that! I love seeing all of your updates and how it is coming along!

Fran

|

|

|

|

Post by connrock on Feb 25, 2010 7:18:00 GMT -5

Hi Adrian,

I've been watching this post all along and you area true artist and mechanical wizard!

As Harley said before stainless steel is very hard to work with.I have seen men I worked with get VERY frustrated when they were almost finished with a job after working on it for many months and messed up while drilling or milling the last operation!

It takes a LOT of care and patience to work with it right up to the very end and to get a mirror polish on it can bring you to the boiling point of frustration!

You have the work ethics and patience to do this and one of the most creative minds I have ever seen!!

I have to add that you are working with a very hard metal and also with a very soft metal,,,,the brass! A tiny scratch in either one will bring tears to your eyes!!

I can't wait to see your future progress and I KNOW you WILL make all of this rough metal into a true thing of beauty!

connrock

|

|

|

|

Post by Jack ( Yorkshire) on Feb 28, 2010 4:35:22 GMT -5

Hi Adrian,

Your amazing , the skill displayed here is outstanding,

Im looking forward to seeing the finished article

All the best

Jack

Yorkshire UK

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Mar 3, 2010 23:35:12 GMT -5

Thank you Tom and Jack! These days I got some time to shine the blade. Man, Tom, you were right, it IS a challange. Funny thing, I tried all sorts of fine sanding approaches using my flat lap machine, but ended up with scratches. So I had to do the fine sanding by hand. But I've done it, I think:    I also finished the hand-guards and fitted the central cab into it. It's a cacoxenite in amethyst:   So, this is how it looks now. Well, in fact right now the blade is no more visible, I thoroughly protected it against scratches during future works.  Tom and Randy - thank you very much for the advices about polishing. Adrian |

|

|

|

Post by Woodyrock on Mar 4, 2010 1:41:14 GMT -5

So far, your sword is absolutely stunning, and it is not yet finished. I like the rest can hardly wait to see it finished.

Woody

|

|

SteveHolmes

fully equipped rock polisher

Member since July 2009

Posts: 1,900

|

Post by SteveHolmes on Mar 4, 2010 7:49:46 GMT -5

Amazing Adrian!!!! Love the Cocoxenite in Amethyst Jewel

Steve

|

|

|

|

Post by rockmanken on Mar 4, 2010 7:52:18 GMT -5

The blade turned out gorgeous. Wish I had your patience. Going to be superb.

Ken

|

|

|

|

Post by moondragon on Mar 4, 2010 9:44:26 GMT -5

The wisdom of a knight, the magic of merlin and the courage of an artist:)

|

|

|

|

Post by Bikerrandy on Mar 5, 2010 22:13:39 GMT -5

I totally missed this thread, you're a true craftsman! That's some amazing work that you're putting in to that, your pride definitely shows  |

|

|

|

Post by connrock on Mar 7, 2010 8:31:45 GMT -5

Hi Adrian,

You did an EXCELLENT job polishing the blade!!!!!!

I KNOW just how difficult it is to do without the right equipment!!

You are very wise to protect the blade now because 1 tiny,tiny scratch will mean hours of hard work and sore arms and fingers.

When I was making my Alamo Bowie Knife I got the blade to a very high shine but not a mirror shine.I left the final polishing until the very end.As you know the higher the finish is the easier it is to show even the slightest scratch.Even a finger mark looks like it is HUGE!! lol

Good luck and if I can help in ANY way PLEASE just ask.

connrock

|

|

Saskrock

fully equipped rock polisher

Member since October 2007

Posts: 1,852

|

Post by Saskrock on Mar 7, 2010 17:57:07 GMT -5

That is turning out fantastic Adrian.

|

|