Erich

spending too much on rocks

Member since November 2015

Posts: 411

|

Post by Erich on Nov 6, 2015 9:45:53 GMT -5

Hi everyone,

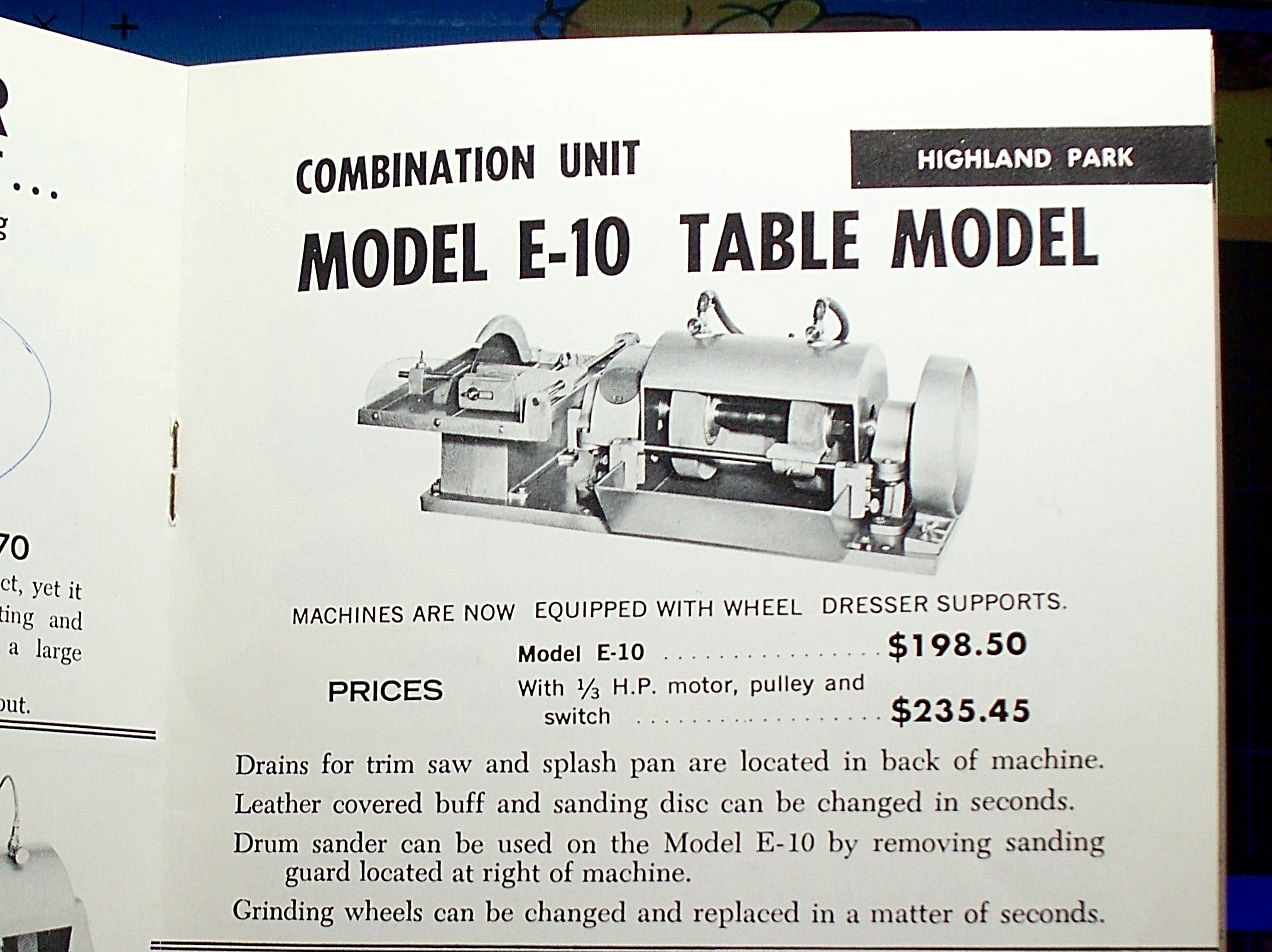

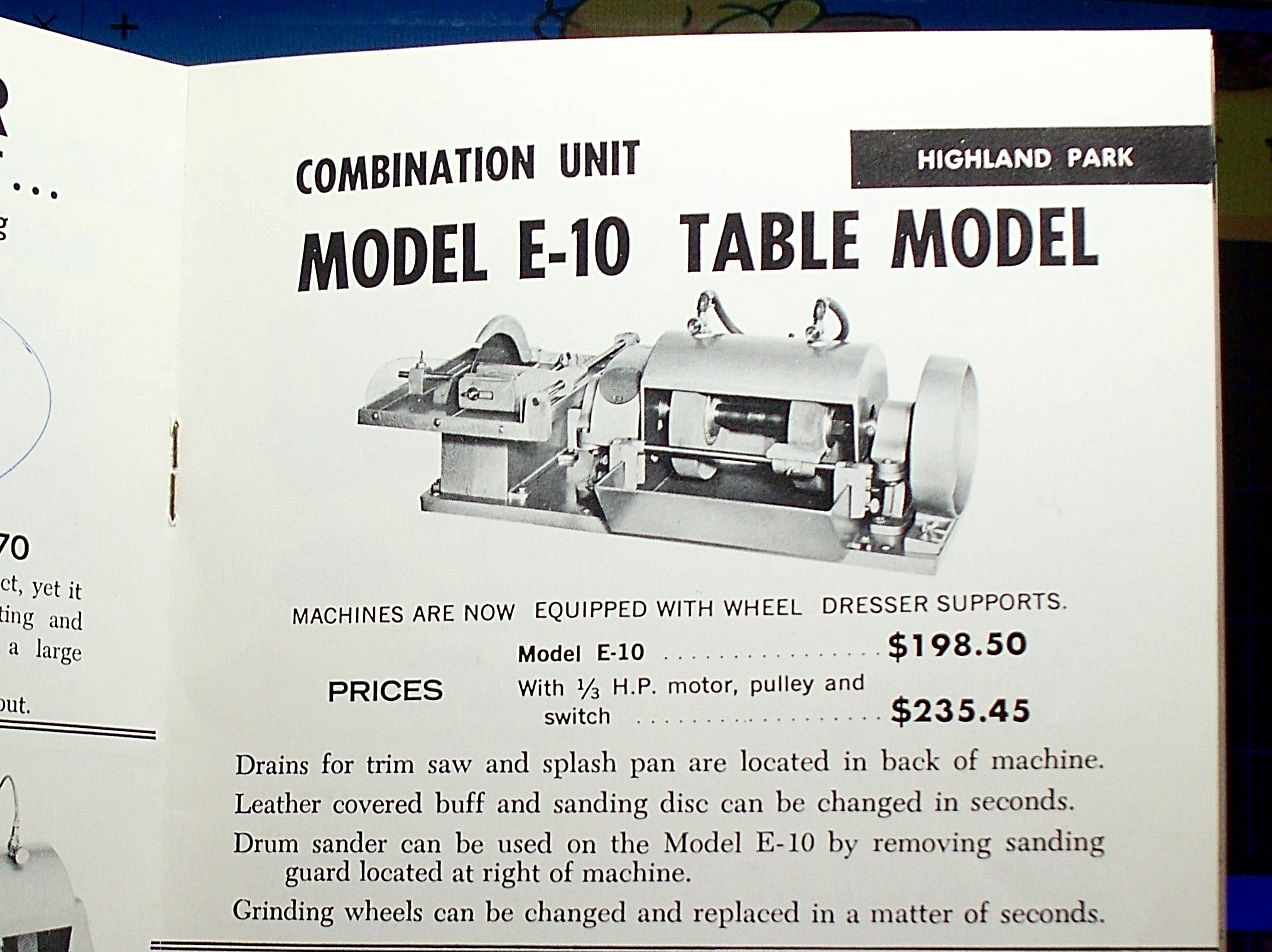

My name is Erich and I'm in south Florida, I'm new in this hobby and just bought 2 old Highland Park 8" trim saw/grinder combo units very inexpensively and am hoping to hear from you all about restoring these units.

So, looking at 8" blades I am looking to understand the difference between a sintered blade and a notched rim blade and which would be best for me. I will be using oil as a coolant and will be cutting agates and jaspers.

I thought to use one unit for the 100 and 220 grit wheel for initial grinding and the other unit for finer grinding using maybe a 400 and 600 grit wheels - I'm hoping to hear some recommendations for grit size for the finer grinding - it would be very helpful!

The two units also came with two 8" flat laps that attach to the end of the arbor one with a leather cover and the other with a sanding round attached by some type of adhesive. Is there some where on line that I can visit to learn how to use these and what type of adhesive to use to attach new sanding discs? What to apply to the leather for buffing and polishing etc.

I've been doing a lot of research on line, but until I can find a local rock club where I can take lessons I sure could use your help.

Thanks to all in advance for your help!

Erich

|

|

|

|

Post by jakesrocks on Nov 6, 2015 11:07:02 GMT -5

Welcome aboard Erich; You'll hear many opinions on the best blades to use, so I won't try to advise you there. If the 100 & 220 grit wheels are hard grinding wheels, you'll want to start out with a 220 grit soft wheel. Then probably a 360 grit followed by 600. The end disc with the sanding round is obviously for sanding. The disc will be attached with what is called Feathering adhesive. You should be able to peel the sanding disc right off of a rubber pad under it. These discs come in many different grit sizes. Get a good selection. Since you're just starting out, I'd use the less expensive Silicon Carbide discs, instead of the expensive diamond discs. The leather disc is for final polish. It too should be attached to a rubber pad with feathering adhesive. I'd peel the old leather off & throw it away since you don't know what type of polish the previous owner was using. New elk hide discs can be bought from any lapidary supply store. I'd suggest you contact our member John at www.jsgemslapidary.com/. He can advise you on the best blades to use. He also gives our members a nice discount on supplies they buy from him. Congratulations on finding a couple of HP machines. They were some of the finest ever built. Don |

|

|

|

Post by captbob on Nov 6, 2015 11:09:11 GMT -5

Hello Erich and welcome to the forum. How far south in Florida are ya? St. Pete here. First off, I believe that you have the model E10. That is a great combo machine. Where the heck did you manage to find two of them in Florida (that I didn't find them!)? Nice score, should be fun restoration projects! I've done a couple similar machines myself. Can you post pictures? I would go with a sintered blade. The head at the end is for a polishing pad, not really called a flat lap. We'll get to that later as you can deal with it at any point in your restoration. Here's one of mine, you can see they clean up nicely - before  after  Are these two machines going to be the whole of your rock grinding shop? What I'm asking is if you are going to have other machines. Reason being, that two of these combo units aren't really what you need. One would be a fantastic base unit for working with rocks, but the second one is too redundant. What do you need two saw / grinder combos for? I would suggest a second machine that is just wheels. Whether they are diamond/SiC wheels or expanding drums, is up to you. Something like this but with two expanding drums that you can change the belts out on would be perfect. Or there are many other type units that would do the same or similar job.  With expanding drums, you just change out the sanding belts to move to different grits. Expanding drums shown on the close end in this photo.  Personally, I would restore the better of the two units, and list the other for sale on craigslist or somewhere and then get a second machine designed to do what you need. You could put two coarse grit wheels on your saw combo unit and figure out how you want to go from there as you are working on your restoration. I would probably go with a 60 and 100 grit wheel combination, 100 and 220 would be my second choice. Lots of options! Hope this helped a little. We'll be here for further questions and watching your restoration project with interest. Figure out how to post pictures, we're a visual bunch and love pictures! Again, welcome - |

|

|

|

Post by captbob on Nov 6, 2015 11:14:49 GMT -5

Don explained the end sanding disc well. Should you end up just keeping one unit, I would have a polishing pad on it. If you go with grit sanding pads on one machine, we'll have a lot more talking to do at that point.

|

|

|

|

Post by jakesrocks on Nov 6, 2015 11:36:17 GMT -5

Another suggestion. Since the older HP machines are highly sought after, If you do a very nice restoration on both machines, you could sell both & get nearly enough for a new all diamond machine. There are many of us, myself included who love the old machines, and will pay top dollar for nice ones.

Don

|

|

|

|

Post by jakesrocks on Nov 6, 2015 11:58:19 GMT -5

Here is what your machines would have looked like new. (I have an old HP catalog)  |

|

|

|

Post by captbob on Nov 6, 2015 12:05:34 GMT -5

"Grinding wheels can be changed and replaced in a matter of seconds."

That's funny!

|

|

|

|

Post by jakesrocks on Nov 6, 2015 12:13:58 GMT -5

I thought so too Bob.

Hey, I just picked up one of those buffing wheel guards off of ebay the other day. Looks like it was never mounted on a machine.

|

|

|

|

Post by captbob on Nov 6, 2015 12:19:37 GMT -5

The piece in your big lot auction? Saw that, nice! Wonder if you could take it to a local metal shop and have them make copies for not too much money? Sorry about the hijack Erich. We tend to go off topic at the drop of a hat around here!  |

|

|

|

Post by jakesrocks on Nov 6, 2015 12:23:05 GMT -5

No, I got this piece a couple days ago. It's that cast aluminum guard at the right end in the catalog pic. My big shipment (3 boxes) will be here tomorrow or Monday.

|

|

Erich

spending too much on rocks

Member since November 2015

Posts: 411

|

Post by Erich on Nov 7, 2015 12:03:32 GMT -5

Thanks gentlemen for responding to my questions and I'll try to answer yours.

First off, I'm in Boca Raton, Fl - not noted as a hotbed of the Lapidary hobby as all we have in my area is sand and coral rock. Not even the agateized coral found up by the Tampa area...

One of my units works well but the other needs new wheels and blade. I've gotten the blade off the disassembled unit but I'm having difficulty getting one of the sealed bearings off to replace the wheels. Whoever had it last didn't maintain it properly so the arbor is rusted just enough to block my attempts to remove the bearing. I'll try the heat gun treatment after trying to fine sand the arbor.

As far as the extent of my tools for the hobby, I eventually want to get either a 14" or 16" slab saw.

While having two of the E10 HP units, my thought was I could get away cheap with cabbing by having 4 different grit wheels plus the 2 discs at the right side of the machine instead of buying an 8" cabbing unit like the "CabKing" unit I've been thinking about. Do you feel I should re think this plan and sell one unit and spring for something else? As I mentioned I am new at this and very open to ideas and don't plan on doing any impulse buying of a 15 hundred dollar or more machine.

I'm fast approaching retirement age and am just looking to have a fun hobby. I love rocks and always have, I get a kick out of cutting a new rock to see what's inside it.

|

|

|

|

Post by jakesrocks on Nov 7, 2015 12:22:16 GMT -5

Erich, I'd make do with what you have for right now. Make sure lapidary is something you want to stick with before sinking a pile of money into it.

Fast approaching retirement age ? Wish I could say that (again). I'm fast approaching pine box age.

|

|

|

|

Post by captbob on Nov 7, 2015 12:27:47 GMT -5

Have you tried something like PB Blaster to soak the stuck bearing for a day or two? May be worth a try before going to heat. I told you what I would do - go with an arbor of some type with a couple expanding drums. You can get different grit sanding belts to run the entire range that you could get in more expensive wheels. I have belts from 100 (I'm sure they make even coarser, but I don't need them) to 25,000 diamond, From there you go to your polishing pad with diamond paste. That just seems the least expensive way to do what you are wanting to do. There may be better options, like a fancy 6 or 8 wheel cabbing unit, but the price just went up. Trying to wrangle a cabbing station out of two of those units you have just doesn't make sense. (to me) Reckon where there is a will there is a way. Maybe if you put an expanding drum on the end of one unit... (?) would take some MacGyvering. Sell one and use the $$ to get the machine that would round out your set up with the kept unit you already have.  |

|

|

|

Post by captbob on Nov 7, 2015 12:31:30 GMT -5

Have you taken one on these apart Don? Could a wheel or drum be rigged in place of one of the saws?

Don't see why not.

hmmmm....

ETA: might be on to something there. 86 the 2nd saw and put an expanding drum there with a hood/drain pan.

|

|

|

|

Post by jakesrocks on Nov 7, 2015 12:51:16 GMT -5

Never taken one apart, but if the shaft is 3/4" all the way through the saw, I don't see why a person couldn't put 2 expanding drums on the saw end. Should be room for 2. But you'd need to fabricate a hood extension & drip pan.

I'd change out the SC grinding wheels for a couple of diamond grinding wheels tho. It's a hassle to change those inside wheels, and diamond wouldn't need to be changed nearly as often as SC wheels.

|

|

Erich

spending too much on rocks

Member since November 2015

Posts: 411

|

Post by Erich on Nov 7, 2015 12:57:49 GMT -5

Well, a bit more elbow grease and the heat gun did the trick so I was able to remove the bearings and wheels. Will be sure to prep the arbor prior to putting anything back together.

Thanks for putting up the old catalog picture of the E10. It looks like everything is still there except on one of the units the water feed system is missing.

I was making do with a jury rigged water system, until I found the second much better conditioned unit, but would like to put back the original type of system.

The expanding drums sound like a good idea and as long as changing the belts is quick it could be the way to go.

|

|

|

|

Post by captbob on Nov 7, 2015 13:05:14 GMT -5

Glad you were able to get everything apart.

Changing the belts actually does take seconds. If you have the drums doubled, like in the machine I posted on the last page, it takes a couple minutes to change the belt on the inside drum, because it has to be slid over the outside drum.

The water valves that you are missing are available at Home Depot. Not original, but they do the job.

|

|

|

|

Post by captbob on Nov 7, 2015 13:08:17 GMT -5

Don, you have a picture of the hood Erich would need to do an drum? Like the one you won in that big auction last week. Just to help show what we're talking about.

|

|

|

|

Post by jakesrocks on Nov 7, 2015 13:32:47 GMT -5

Don, you have a picture of the hood Erich would need to do an drum? Like the one you won in that big auction last week. Just to help show what we're talking about. Equipment hasn't arrived yet Bob. I'll take a pic of another unit in the HP catalog. It'll give him the idea. |

|

Erich

spending too much on rocks

Member since November 2015

Posts: 411

|

Post by Erich on Nov 7, 2015 13:37:14 GMT -5

Thanks again guys! Appreciate all the advice. CaptBob,the machine you posted, did you just buy the arbor by itself? I do like that configuration.

|

|