jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Nov 17, 2019 7:36:35 GMT -5

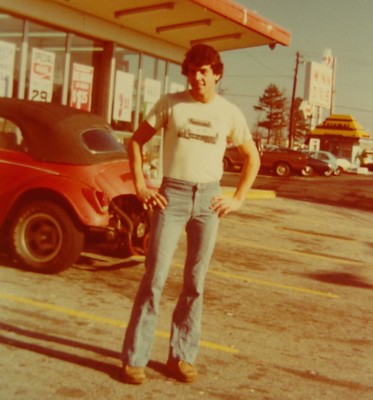

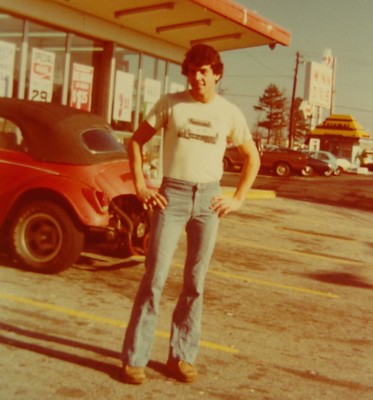

EricD. I hate to hijack out here. I'll just add another idea of another mechanical variable speed pulley system at the bottom of this post. I love Baja V-dubs. Had 2 about 40 years ago lol. I see you replaced the front suspension with wild long travel. I get it, it takes like 4 bolts to remove original front torsion system. The swing arms look modified too. Is this so ? And the floor pan says it is a VW frame, hard to tell at first. Wicked. Awesome build. I am senior in high school here, dual port MOFOCO engine line bored for 92mm jugs, cam and Holley carb. Low tires, set up for 1/8 mile. Used to embarrass the rich kid's V8's racing them with this buggy in the city where acceleration and braking ruled.  These are 2 speed and 3 speed pulleys on a Covington rock saw. Left 3 speed pulley and right 2 speed pulley make 6 speeds for rock feed rate Spring loaded tensioner for both pulleys. Motor drive at bottom. Probably better to use a simple motor-on-hinge tensioner for a tumbler as mentioned. Of course a tumbler would only require one 3 speed pulley for coarse grind.

|

|

|

|

Post by TheRock on Nov 17, 2019 13:57:25 GMT -5

I Thought the Topic was a Variable speed motor for a tumbler? Not how thick the slurry is or how long to tumble.  Isn't tumbling speed relative to a variable speed controller ? Yes once a Person decides on how he will safely build the variable speed device. Then that that would be the next step, the speed you are going to turn the barrels. But Thickness of Slurry and Length of time time is about as relevant at that point, as the color your going to paint it! Until you figure out how to control the variable speed it really doesn't matter.  |

|

|

|

Post by TheRock on Nov 17, 2019 15:32:58 GMT -5

|

|

rockbiter

having dreams about rocks

Member since October 2019

Posts: 60

|

Post by rockbiter on Nov 17, 2019 23:26:06 GMT -5

Dang, this thread blew up while I was out rockhounding! Gonna take me a bit to go over all this but thanks for all the great info you guys!

|

|

rockbiter

having dreams about rocks

Member since October 2019

Posts: 60

|

Post by rockbiter on Nov 17, 2019 23:41:51 GMT -5

I have played with that for my rock saw, but the problem with using it for the tumbler is that knowing the shaft speed is only half the battle. You have two more variables to factor in - shaft circumference and barrel circumference. I haven't been able to get that far because I wasn't sure how I was going to bulk up the shaft size to avoid hitting the fernco clamp bolts (see forum.rocktumblinghobby.com/thread/89411/variant-jamesps-ultimate-tumbler-barrel ). I think the shaft will be 1.0625" diameter and the barrel is 7.0625" diameter so... What is circumference again, pi r squared? I'm too tired to figure it out right now! |

|

|

|

Post by TheRock on Nov 18, 2019 1:32:23 GMT -5

I have played with that for my rock saw, but the problem with using it for the tumbler is that knowing the shaft speed is only half the battle. You have two more variables to factor in - shaft circumference and barrel circumference. I haven't been able to get that far because I wasn't sure how I was going to bulk up the shaft size to avoid hitting the fernco clamp bolts (see forum.rocktumblinghobby.com/thread/89411/variant-jamesps-ultimate-tumbler-barrel ). I think the shaft will be 1.0625" diameter and the barrel is 7.0625" diameter so... What is circumference again, pi r squared? I'm too tired to figure it out right now! 7.0625 X 3.14 = 22.17625 <<<< Barrel 1.0625 X 3.14 = 3.33625 Shaft |

|

rockbiter

having dreams about rocks

Member since October 2019

Posts: 60

|

Post by rockbiter on Nov 18, 2019 2:25:22 GMT -5

I have played with that for my rock saw, but the problem with using it for the tumbler is that knowing the shaft speed is only half the battle. You have two more variables to factor in - shaft circumference and barrel circumference. I haven't been able to get that far because I wasn't sure how I was going to bulk up the shaft size to avoid hitting the fernco clamp bolts (see forum.rocktumblinghobby.com/thread/89411/variant-jamesps-ultimate-tumbler-barrel ). I think the shaft will be 1.0625" diameter and the barrel is 7.0625" diameter so... What is circumference again, pi r squared? I'm too tired to figure it out right now! 7.0625 X 3.14 = 22.17625 <<<< Barrel 1.0625 X 3.14 = 3.33625 Shaft So that's about 6.6 turns of the shaft per barrel turn. So I need the shaft speed to max out around 600 rpm. Sweet! That helps, thanks. |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Nov 18, 2019 8:01:21 GMT -5

The ratios can be multiplied times the motor rpm easily. Two fractions times the rpm.

For a 10 inch barrel:

1700 rpm x 2/12 x 1/10 = 28.33 rpm.

2 inches is motor pulley

12 inches is big pulley

1 inch is shaft diameter

10 inches is barrel diameter

Changing to an 8 inch barrel 8 inch barrel:

1700 rpm x 2/12 x 1/8 = 35.4 rpm

For an 8 inch barrel with motor pulley changed to 1.5 inches:

1700 rpm x 1.5/12 x 1/8 = 26.6 rpm

For a 12 inch barrel with motor puller changed to 3 inches:

1700 rpm x 3/12 x 1/12 = 35.4 rpm

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Nov 18, 2019 8:23:30 GMT -5

Isn't tumbling speed relative to a variable speed controller ? Yes once a Person decides on how he will safely build the variable speed device. Then that that would be the next step, the speed you are going to turn the barrels. But Thickness of Slurry and Length of time time is about as relevant at that point, as the color your going to paint it! Until you figure out how to control the variable speed it really doesn't matter.  The variable drive would be a fine addition. I was just playing devil's advocate. Over the past years have made changes to the tumblers that over loaded the initial motor installation. Especially during the grueling coarse grind. As a minimum it would be nice to run it fast during the initial coarse grind. For the last coarse grit addition - it would be nice to slow the barrels for the final run and for the 220 run. Slowing it for soft stuff, bigger barrels, finish steps, list goes on and on. |

|

|

|

Post by TheRock on Nov 18, 2019 23:09:17 GMT -5

So jamesp Just to Sum this All Up I Would Like you to tell me the barrel speed on The Following, Does the speed matter with dia of barrel? Coarse Grind : 220 Grit: 500 Grit: Polish Grit: I would also Like to add Photo Electric Tachometer. I used to have one but it got away from me.  |

|

EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Nov 18, 2019 23:25:12 GMT -5

So jamesp Just to Sum this All Up I Would Like you to tell me the barrel speed on The Following, Does the speed matter with dia of barrel? Coarse Grind : 220 Grit: 500 Grit: Polish Grit: I would also Like to add Photo Electric Tachometer. I used to have one but it got away from me.  You can use your phone for a tach. Put a line on the barrel. dial in a strobe app to flash when your line goes by |

|

|

|

Post by TheRock on Nov 19, 2019 1:46:46 GMT -5

So jamesp Just to Sum this All Up I Would Like you to tell me the barrel speed on The Following, Does the speed matter with dia of barrel? Coarse Grind : 220 Grit: 500 Grit: Polish Grit: I would also Like to add Photo Electric Tachometer. I used to have one but it got away from me.  You can use your phone for a tach. Put a line on the barrel. dial in a strobe app to flash when your line goes by WoW! You Hillbillies Have Everything!  Hey thanks brother, I didn't know that existed! 30 years ago I payed a few hundred for a Tiff Instrument Photovalactic Tach I think it was called Yeah I used it several times loaned it out and the rest is history. Here's the link for one I got for my blackberry Samsung 8 |

|

rockbiter

having dreams about rocks

Member since October 2019

Posts: 60

|

Post by rockbiter on Nov 19, 2019 1:57:52 GMT -5

Okay, I liked the video about the VFD but I'm considering a cheaper option. What do you think about this TheRock?  Should have plenty of power for pretty cheap and it doesn't slow down when you add more of a load. No computer hookup or digital display but that's okay with me. In one review it says you can bypass the foot pedal hookup using a magnet. Wish it were more like 250 watt instead of 550, but at least it should have plenty of power. |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Nov 19, 2019 4:58:13 GMT -5

Okay, I liked the video about the VFD but I'm considering a cheaper option. What do you think about this TheRock?  Should have plenty of power for pretty cheap and it doesn't slow down when you add more of a load. No computer hookup or digital display but that's okay with me. In one review it says you can bypass the foot pedal hookup using a magnet. Wish it were more like 250 watt instead of 550, but at least it should have plenty of power. I'm not The Rock but may I toss a hint at this question. The contents behind the little black plug in center of photo is going to cause a serious problem using this motor on a rotary tumbler.  |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Nov 19, 2019 5:47:58 GMT -5

So jamesp Just to Sum this All Up I Would Like you to tell me the barrel speed on The Following, Does the speed matter with dia of barrel? Coarse Grind : 220 Grit: 500 Grit: Polish Grit: I would also Like to add Photo Electric Tachometer. I used to have one but it got away from me.  Car body analogy: Coarse grind is likened to fixing a wrecked car body. Use hammers, mallets, slide hammers, torch, patch welds, 9 inch angle grinders, etc. 220-500-1000-polish is the precision finish steps in body work. Use sand paper, thin coats of filler, rasp, fine grinding. There are two completely different steps in rock tumbling. coarse and finishing. Speeds here we go: 1) coarse grind speed - As fast as you can go without damaging rocks. The medieval step of tumbling. My favorite step. Why not go faster, this step takes 80% of the time in most cases. Make/buy a tumble specifically for this step. Stouter the better. The factory boys will not make a fast rotary due to liable, higher cost of higher quality components, increased wear, and increased gas production causing blow outs. All weapons on deck, higher speeds, heavy duty bearings, thicker shafts, rugged wear resistant barrels, variable speeds, lower barrel fills, aggressive round barrels(not hex), more aggressive silicon carbide, bigger barrels, slurries, no media, constant abrasive additions and mud clean outs, etc. Whatever it takes. Just maintain a balanced mix of rock sizes and 65 to 75% barrel fill. I prefer 60 to 90 rpm for 6" I.D. barrels. 75% of that for 8" I.D.. barrels (only when using sticky slurry). 2) finishing speed - 220-500-1000-polish - Slow is best, and use a higher(80 to 85%) barrel fill. This is the passive steps in tumbling. With media and/or slurry added use 25 to 30 rpm for 6 inch I.D. barrel, or 6/8 x (25 to 30 rpm) = 19 to 23 rpm for an 8 inch I.D. barrel, or 8/10 x (19 to 23 rpm) = 15 to 18 rpm for a 10 inch I.D. barrel. Or better, use a vibe. No need to adjust speeds in 220-500-1000-polish, if your shafts are turning a 6 inch ID barrel at 25 to 30, they will turn an 8" at 19 to 23 and a 10" at 15 to 18. The surface speed will remain the same regardless of barrel diameter for a given speed of shafts. In this video the black 8" I.D. barrels are running glass in silicon carbide 8 and turning about 60 rpm(same as a 6"I.D. barrel turning about 80 rpm). The black HDPE can handle the raw cheapo silicon carbide 8. And the fast speeds. No need for variable speed, run that witch wide open ! Peddle to the metal that's right. Coarse grind is nasty, loud and dirty like a concrete mixer. Best to put the coarse grind machine as far away from humans as possible. The two PVC 5" I.D. barrels are running finish abrasives at about 40 rpm. PVC is OK for finer abrasives 220-500-1000-polish. |

|

nik

spending too much on rocks

Member since May 2019

Posts: 315

|

Post by nik on Nov 19, 2019 8:05:34 GMT -5

I'm using one of the 550w sewing machine motors on my cab grinder. It does not have any issue turning 4 heavy sintered wheels, an 8" soft wheel, an 8" expanding drum, and a heavy face plate on a 1" shaft at whatever speed it is set to. But at most, it runs for 8 hours a week. I think you would burn through brushes and commutator bars pretty fast running full time on a tumbler.

It may not be the cheapest or most rube goldbergian solution, but a 1/3-1/2 hp induction motor with either step pulleys or a variable frequency drive would be the most reliable and least likely to catch fire.

|

|

rockbiter

having dreams about rocks

Member since October 2019

Posts: 60

|

Post by rockbiter on Nov 19, 2019 14:17:47 GMT -5

Aww freaking crap. Grrr I didn't read that one close enough. They do make them brushless jamesp . Good catch, thanks. This is what I was after:  Now am I missing anything? |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Nov 19, 2019 15:00:09 GMT -5

Aww freaking crap. Grrr I didn't read that one close enough. They do make them brushless jamesp . Good catch, thanks. This is what I was after:  Now am I missing anything? If it is brushless it may be a good start. You have GOT to have continuos duty. Many sewing machines have an AC motor that runs continuously with a clutch to engage. Most sewing machine applications are intermittent duty so beware. That says servo motor so I am guessing it is DC motor. 3/4 hp is a lot of motor for 100 to 120 pounds of rock. AND you best look at the final current draw due to the variable controller. Some controller designs can draw some serious current. And heat. Anything but straight 60 hz AC motors are going to drop in power efficiency. Your call. Check out this place. I buy all my sheaves, pillar blocks and often motors here to build a tumbler. They have variable drives too. www.surpluscenter.com |

|

rockbiter

having dreams about rocks

Member since October 2019

Posts: 60

|

Post by rockbiter on Nov 19, 2019 16:23:19 GMT -5

Aww freaking crap. Grrr I didn't read that one close enough. They do make them brushless jamesp . Good catch, thanks. This is what I was after:  Now am I missing anything? If it is brushless it may be a good start. You have GOT to have continuos duty. Many sewing machines have an AC motor that runs continuously with a clutch to engage. Most sewing machine applications are intermittent duty so beware. That says servo motor so I am guessing it is DC motor. 3/4 hp is a lot of motor for 100 to 120 pounds of rock. AND you best look at the final current draw due to the variable controller. Some controller designs can draw some serious current. And heat. Anything but straight 60 hz AC motors are going to drop in power efficiency. Your call. Check out this place. I buy all my sheaves, pillar blocks and often motors here to build a tumbler. They have variable drives too. www.surpluscenter.comThanks, I'll check it out. I called consew and the csm1000 motor is rated for continuous duty. They didn't see a problem with using it for a rock tumbler. I agree that 550w is awfully high power draw. I could be incorrect but I'm hoping to be able to run it at lower speed to reduce consumption. I realize that that will lower efficiency but my understanding is that these motors have overall much better efficiency than AC motors so hopefully I'm still ahead. It only uses 550 watts when running at full speed, correct? |

|

EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Nov 19, 2019 17:42:25 GMT -5

The 550 watt rating is at the highest load that it can maintain it's rated speed (4500rpm)

|

|

Hey thanks brother, I didn't know that existed! 30 years ago I payed a few hundred for a Tiff Instrument Photovalactic Tach I think it was called Yeah I used it several times loaned it out and the rest is history.

Hey thanks brother, I didn't know that existed! 30 years ago I payed a few hundred for a Tiff Instrument Photovalactic Tach I think it was called Yeah I used it several times loaned it out and the rest is history.