rockbiter

having dreams about rocks

Member since October 2019

Posts: 60

|

Post by rockbiter on Nov 26, 2019 20:42:52 GMT -5

Mars ECM CatalogPage 3 has the same setup from 1/5 - 1 hp. Page 8 shows the PWM speed controller for the Evergreen lineup of motors. Very interesting, knave. However, the evergreen line has been discontinued and I think the price would be prohibitive for most people on the azure line, having to buy the controller separately. The brushless DC servo sewing machine motor I got that comes with a controller, for $120, seems like a pretty good choice for the $. Consew has been in business for a long time so I am hoping they use a good motor. The top speed and top amp draw are both too high for a tumbler, but luckily reducing one also reduces the other. I am working on building my tumbler still so the jury is still out. And only time will tell if it will last well. |

|

|

|

Post by knave on Nov 26, 2019 21:41:31 GMT -5

Mars ECM CatalogPage 3 has the same setup from 1/5 - 1 hp. Page 8 shows the PWM speed controller for the Evergreen lineup of motors. Very interesting, knave. However, the evergreen line has been discontinued and I think the price would be prohibitive for most people on the azure line, having to buy the controller separately. The brushless DC servo sewing machine motor I got that comes with a controller, for $120, seems like a pretty good choice for the $. Consew has been in business for a long time so I am hoping they use a good motor. The top speed and top amp draw are both too high for a tumbler, but luckily reducing one also reduces the other. I am working on building my tumbler still so the jury is still out. And only time will tell if it will last well. I didn’t realize Evergreen was discontinued. We still use Azure at work. That sewing machine motor sounds like a really good option. Keep us posted. On the other hand, if these permanent magnet brushless motors will save $$ per month, it wouldn’t take long to recoup the extra cost of the $80 controller. |

|

|

|

Post by Drummond Island Rocks on Nov 30, 2019 20:49:09 GMT -5

I have no horse in this race but I did come across an interesting home brew piece of equipment the other day. It looks like it is set up for variable speed. Not sure why there is a speed control on the motor and one mounted to the poly arbor. jamesp TheRock   Edit: found this info on the web They were sold as a universal tool "Variable speed motor" from the late 60's on ward. I don't think they came as OE on any of the machines, but I am not sure about that. They are in the old catalogs online. To my knowledge they made two versions one, without a remote speed adjustment and one with a remote speed adjustment. Yours being the latter which were also the later in production compared to the non remote speed adjustment versions. Chuck |

|

|

|

Post by Drummond Island Rocks on Nov 30, 2019 20:55:29 GMT -5

1968 sears ad for the above motor says dial any speed from 500 to 5000 RPM under full load. Full torque at ALL speeds.   Chuck |

|

|

|

Post by TheRock on Dec 1, 2019 5:07:57 GMT -5

1968 sears ad for the above motor says dial any speed from 500 to 5000 RPM under full load. Full torque at ALL speeds.   Chuck Wow nice find Chuck that looks like a pretty neat Gizmo. It's not a BINFORD but what the Heck! It is most likely a DC motor or it has brushes being it goes in reverse. Not a bad alternative to what everyone is doing. Personally - I've developed some bad Habits over the years! If it takes a 2X4 why not use a 2X6? If it takes a 2X6 why not throw a 2X12 at it. I overbuild everything I do. Sometimes its good sometimes it's Bad $$$ I just like stuff to work when I get done. And of course when it comes to MTRs and what not that is where my trade and experience comes in. The VFD is a proven product It may only need a 1/3Hp 220V 3PH motor but I pulled an Emeril Lagasse and kicked it up a notch and threw a 1/2 HP at it and as James says they sell 3PH motors for pennies a pound so what the hey. I know without a doubt it will work. As far as shaving every ounce of efficiency. I did that too! It's called 38 Solar Panels.  It's like TIM TAYLOR m o r e P O W E R!! aarrrrggh! aarrrggh! aarrrggh!

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Dec 1, 2019 6:11:49 GMT -5

This horse has been put out to the pasture.

Home brewed tumbling method perfected and unchanged for over 5 years.

My tumbling research was devoted to optimizing coarse and finishing steps using rotaries and vibes for:

barrel diameters/shapes

abrasives

speeds

vibration

slurries

grind/polish rates

tumbling large rocks and soft materials

power consumption

reliability

cost effectiveness

repetitiveness

Outcome was simple but hard earned - rugged 6 inch I.D. barrels, 30 and 60 rpm tumblers, tuned Vibrasonic vibe, super coarse SiC, SiC 500, AO 220, AO polish, clay, sugar.

And lots of rocks and glass !

Early this year I hauled off a pick up truck full of experimental tumblers, sheaves, motors, abrasives, barrels of all sizes, etc. that had accumulated from 2012 to 2016.

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Dec 1, 2019 7:10:03 GMT -5

I think we should have a contest.

Who can reduce 5 pounds of 3/4" marbles in weight the most in a week in a coarse run and not bruise them deeply. Or not be concerned with the bruises.

7 days of rolling. Use any barrel, abrasive, speed, slurry, media, etc.

My set up would be a 10 pound barrel, 6 inches inside diameter, clay slurry, 60 rpm, a 1 pound oval rock with 4 pounds of 1 to 1.5 inch roundish agates added as needed, 65-70% barrel fill(depending on sound), 5 pounds marbles, SiC 30 recharged and slurry adjusted every 2 days.

That's about as cold blooded a coarse run as I can dream up.

Call it for the sake of science. To heck with bragging rights, it is valuable knowledge.

|

|

|

|

Post by TheRock on Dec 1, 2019 8:27:10 GMT -5

I think we should have a contest. Who can reduce 5 pounds of 3/4" marbles in weight the most in a week in a coarse run and not bruise them deeply. Or not be concerned with the bruises. 7 days of rolling. Use any barrel, abrasive, speed, slurry, media, etc. My set up would be a 10 pound barrel, 6 inches inside diameter, clay slurry, 60 rpm, a 1 pound oval rock with 4 pounds of 1 to 1.5 inch roundish agates added as needed, 65-70% barrel fill(depending on sound), 5 pounds marbles, SiC 30 recharged and slurry adjusted every 2 days. That's about as cold blooded a coarse run as I can dream up. Call it for the sake of science. To heck with bragging rights, it is valuable knowledge. Take the Bruisin part off of it and I have a special 10 lb hammer friend I fondly refer to as S L U G G O! If Sluggo cant do it nothing can! Contest? Hell no!! I don't have me Super Deluxe VFD Tumbler going yet, and after I get it going, you gotta give me 10 years of practice to get me recipe honed in. Awe hells bells Ill be dead by then so you can just win by forfeit!  |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Dec 1, 2019 8:37:30 GMT -5

I think we should have a contest. Who can reduce 5 pounds of 3/4" marbles in weight the most in a week in a coarse run and not bruise them deeply. Or not be concerned with the bruises. 7 days of rolling. Use any barrel, abrasive, speed, slurry, media, etc. My set up would be a 10 pound barrel, 6 inches inside diameter, clay slurry, 60 rpm, a 1 pound oval rock with 4 pounds of 1 to 1.5 inch roundish agates added as needed, 65-70% barrel fill(depending on sound), 5 pounds marbles, SiC 30 recharged and slurry adjusted every 2 days. That's about as cold blooded a coarse run as I can dream up. Call it for the sake of science. To heck with bragging rights, it is valuable knowledge. Take the Bruisin part off of it and I have a special 10 lb hammer friend I fondly refer to as S L U G G O! If Sluggo cant do it nothing can! Contest? Hell no!! I don't have me Super Deluxe VFD Tumbler going yet, and after I get it going, you gotta give me 10 years of practice to get me recipe honed in. Awe hells bells Ill be dead by then so you can just win by forfeit!  Lol. Confessing to being jealous of the 3 phase rig and programability. You certainly should try my 6" id barrel set up when you get your machine set up. I suggest 4 feet long shafts as a minimum so you can keep plenty of coarse grind barrels rolling. Or use tiers but watch out for gas blow outs spilling abrasive on lower levels bearings. |

|

|

|

Post by TheRock on Dec 4, 2019 21:56:34 GMT -5

Take the Bruisin part off of it and I have a special 10 lb hammer friend I fondly refer to as S L U G G O! If Sluggo cant do it nothing can! Contest? Hell no!! I don't have me Super Deluxe VFD Tumbler going yet, and after I get it going, you gotta give me 10 years of practice to get me recipe honed in. Awe hells bells Ill be dead by then so you can just win by forfeit!  Lol. Confessing to being jealous of the 3 phase rig and programability. You certainly should try my 6" id barrel set up when you get your machine set up. I suggest 4 feet long shafts as a minimum so you can keep plenty of coarse grind barrels rolling. Or use tiers but watch out for gas blow outs spilling abrasive on lower levels bearings. I was thinking about making it a multi Tear jobbie but going 3' long but I don't like blow outs! This unit will be inside and if it going to buck up my Lap shop that will be a Negatory. I may have to go a lower speed. I like the idea of steel endcaps with bolts and wing nuts. |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Dec 5, 2019 3:46:04 GMT -5

Gas has been a problem over the years TheRock. Especially when tumbling glass and experimenting with lime and dolomitic slurry additives. The expandable rubber Fernco caps have been a life saver since they bulge long before blowing off. Especially the 6 inch caps on the 8 inch barrels. They have bulged out 3 inches at times because tumblers were not checked for 3 to 4 days. Two band clamps are often used doing glass to prevent the Fernco caps from blasting off. And not machine made glass but hand blown and fused glass that has mega gas bubbles in it. At times the band clamps must be loosened with the barrel facing a place to retrieve the cap. I have had the caps launch 100 feet in the air again because they were not checked for several days. But you are forewarned because of the obvious bulging shape of the bloated cap. Bulge rate is typically 1/2" the first day, 1 inch the 2nd day, 1.5 the third, etc. So you are given forewarning that gas is an issue. You have like a dozen tumblers, don't you have blow outs ? |

|

rockbiter

having dreams about rocks

Member since October 2019

Posts: 60

|

Post by rockbiter on Dec 6, 2019 23:35:34 GMT -5

Got my tumbler going finally! See it here. |

|

EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Dec 6, 2019 23:42:57 GMT -5

Got my tumbler going finally! See it here. I do believe I will have to purchase one of those drive units. The price is just too good for what it can do. I respect TheRock for going s step further with programability, but he well overdid the HP on his and will end up with a greater amp draw IMHO. Some electric motors can suck up a ton of juice even at idle. |

|

rockbiter

having dreams about rocks

Member since October 2019

Posts: 60

|

Post by rockbiter on Dec 16, 2019 16:36:54 GMT -5

Got my tumbler going finally! See it here. I do believe I will have to purchase one of those drive units. The price is just too good for what it can do. I respect TheRock for going s step further with programability, but he well overdid the HP on his and will end up with a greater amp draw IMHO. Some electric motors can suck up a ton of juice even at idle. Hope it treats you well! I agree, the price is awesome for the functionality and economy. My only concern is the heat buildup on the control box. I might mount a tiny fan blowing at the heatsink. |

|

jes90

off to a rocking start

Looking for help with a DIY thing!

Looking for help with a DIY thing!

Member since August 2022

Posts: 1

|

Post by jes90 on Aug 4, 2022 14:57:51 GMT -5

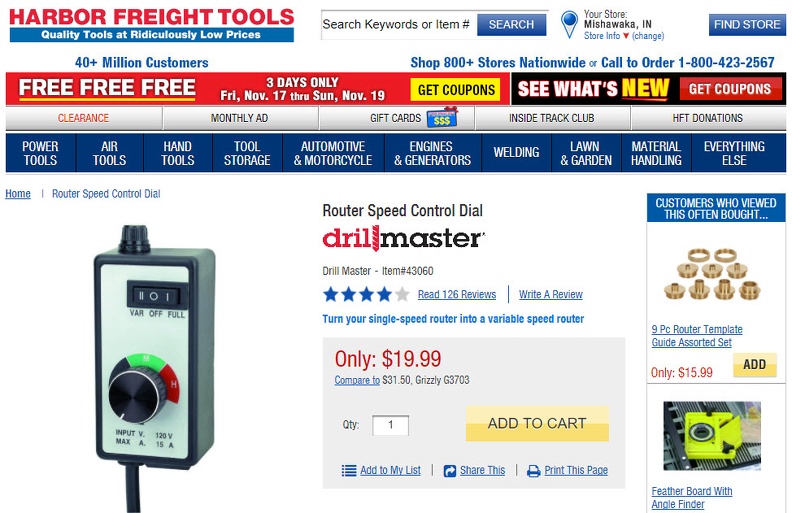

What could I use to control this saw? Not sure what type of motor it is. But would love to be able to slow it down a bit! Saw you had a HF saw also but this one is a 7 in. Anything would be helpful!  As Long as it is not an Induction Motor it will work, an Induction motor Is like off a furnace either a Base Mount type or a direct dive Their are many larger Induction motors, but a small 1/4 to 1/2hp motor would be plenty. I dont know how many Barrels you are rotating but most likely you will never need over a 1/2HP capacitor start would give you the oooOOMPH to start several Barrels. Now what that might be good for is a router a router has brushes and so does a small tile saw these motors are non inductive. Guys like tile saws to run slower and it would be good for that.slower Here is a harbor freight router speed control. Its not easy to safely control a Induction Motor without spending a Little money on a Frequency Drive For Induction Motor 220V Single Phase Depending on which one you choose you will have to run 220V their for you will need a 220V single phase Motor. Good Luck     |

|