EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Nov 19, 2019 18:52:28 GMT -5

If it is brushless it may be a good start. You have GOT to have continuos duty. Many sewing machines have an AC motor that runs continuously with a clutch to engage. Most sewing machine applications are intermittent duty so beware. That says servo motor so I am guessing it is DC motor. 3/4 hp is a lot of motor for 100 to 120 pounds of rock. AND you best look at the final current draw due to the variable controller. Some controller designs can draw some serious current. And heat. Anything but straight 60 hz AC motors are going to drop in power efficiency. Your call. Check out this place. I buy all my sheaves, pillar blocks and often motors here to build a tumbler. They have variable drives too. www.surpluscenter.comI have speed controllers on some inline duct fans, and they draw the same amperage on low speed as they do on high speed |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Nov 19, 2019 22:04:56 GMT -5

I'm sticking with AC motors and mechanical reduction.

|

|

EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Nov 19, 2019 22:37:22 GMT -5

I'm sticking with AC motors and mechanical reduction. That is the logical way to go. It's cheaper. It's reliable. The only component that can need replacement is bearing/motor/belt. And a pulley/sheave doesn't cost much. If you know what your target RPM is, you do not need variable speed unless you want to do multiple jobs with one machine. Doing polish in a rotary tumbler is not a wise thing to attempt, unless you are dry tumbling with corn cob, apparently. In which case you don't need adjustable rpm. I'm all for adjustability but I think it would be more "profitable" to adjust grit amount, time, cleanouts in your vibe than focus on making your rotary an "all-in-one" machine |

|

rockbiter

having dreams about rocks

Member since October 2019

Posts: 60

|

Post by rockbiter on Nov 19, 2019 22:52:42 GMT -5

If it is brushless it may be a good start. You have GOT to have continuos duty. Many sewing machines have an AC motor that runs continuously with a clutch to engage. Most sewing machine applications are intermittent duty so beware. That says servo motor so I am guessing it is DC motor. 3/4 hp is a lot of motor for 100 to 120 pounds of rock. AND you best look at the final current draw due to the variable controller. Some controller designs can draw some serious current. And heat. Anything but straight 60 hz AC motors are going to drop in power efficiency. Your call. Check out this place. I buy all my sheaves, pillar blocks and often motors here to build a tumbler. They have variable drives too. www.surpluscenter.comI have speed controllers on some inline duct fans, and they draw the same amperage on low speed as they do on high speed Hmm. I'm trying to understand how that makes sense. Seems like slower speed should reduce torque which in turn should reduce current draw. Efficiency drops at lower speed, maybe it comes out a wash? You have tested the amp draw at different speeds? |

|

EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Nov 19, 2019 23:06:21 GMT -5

I have speed controllers on some inline duct fans, and they draw the same amperage on low speed as they do on high speed Hmm. I'm trying to understand how that makes sense. Seems like slower speed should reduce torque which in turn should reduce current draw. Efficiency drops at lower speed, maybe it comes out a wash? You have tested the amp draw at different speeds? The amp draw remains constant. The difference is minimal. They have a speed controller similar to the one in post #1 |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Nov 20, 2019 6:27:06 GMT -5

This is a great thread. Different speeds for coarse and finishing steps is all good. Certainly a forward move. This is how I dealt with various speeds: I have a slow running specialty tumbler set up for running SiC 500 for 10 days after the coarse grind. It will run two 8 pound 6" made-to-vibe-size HDPE barrels at a slow 20 rpm, vibe has 8 pound capacity. This is an intermediate step between coarse and the vibe. The SiC 500 does a great job of removing the coarse scratches(instead of using SiC 220) and also preps for vibe abrasives. This little tumbler does two 8 pound loads in 10 days and the vibe does one 8 pound load in 5 days. So they are timed in harmony. To feed this tumbler I load the big faster rolling coarse grind tumbler up with 6-7 barrels totaling 100+ pounds of rock. I run it for 6 to 8 to 10 to 12 weeks until the rocks are well rounded and *shut it down for several months until the SiC 500 rotary and vibe has finished the 100+ pounds. Some barrels have glass and are removed from the coarse grind early, the benefit of having multiple barrels instead of 1 or 2 large barrels. This makes time to sort the coarse grind rocks, select good mixed size batches for SiC 500 tumbler, store rocks to avoid running big noisy tumbler outside in winter temps, and in general take a break from the labor of feeding the big tumbler coarse grit and constant clean outs. Just saying, variable speed/different speeds can be organized in a way that the loads are reaching completion in harmony with your equipment. The SiC 500 tumbler is barely loaded running two 8 pound barrels with this slow turning 1050 rpm AO Smith 1/8 hp air over motor. It is near silent at 20 rpm barrel speed and works good in the home basement/carport. Has a 1/2" shaft making it easy to use sheaves with long lasting automotive v-belts. It will run a 10" diameter 40 pound barrel too. Even turning 40 pounds the air over motor is not loaded much at 12 rpm. I get these small motors used at HVAC shops for cheap. The low rpm allows a smaller main sheave. 1/8, 1/10, 1/12 HP, 1050 RPM NEW CENTURY/AO SMITH ELECTRIC MOTOR. A.O. Smith 98 1/8-1/10 -1/12 HP 115 Volt 1050 RPM Blower Motor $95 on EBAY Continuous Duty, Air Over Shaded Pole 60 Hz Auto Protector 40 Degrees C Ambient OEM Replacement 1/2" Dia. Flatted Shaft 1/8~1/10 ~1/12 HP 1050 RPM 115 Volt 5.1-3.5-3.0 Amps Sleeve Bearing Rotation: CCWLE 3 Speed  This is the slow running intermediate tumbler and was built in a day on 2x10's. 3/4 inch shafts. Sealmaster bearings with grease fittings. Automotive v-belt. 11 inch/3/4 inch bore Taperlock Cast iron sheave. 1/8 hp with 1/2 inch bore pinion. Great motor for running 8 to 40 pound barrels at lower finishing speeds. Runs tilted to keep barrel against single end roller.  Note slurry paint job on open cage motor. No ill effects so far but it will EAT bearings. Had to post this for TheRock Bob in light of his totally awesome pristine shop. Dammit Bob rock tumbling is just a nasty operation. I do keep the insides of those barrels well maintained. It's all about the rocks ! About 200 sq ft of the gravel floor is now concreted together with rock slurry. Man that slurry makes fine Portland. The vibe is kept a distance away in much neater/cleaner conditions.  Note on HVAC grade 'air over' motor: Roof top A/C units have seriously HOT air over them. Not to mention driving a fan is brutal duty for a motor. A well sized tumbler has much lighter duty demand. 1/8 hp is a good size for most tumblers running 12 to 24 pounds at most any speed. |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Nov 20, 2019 6:40:33 GMT -5

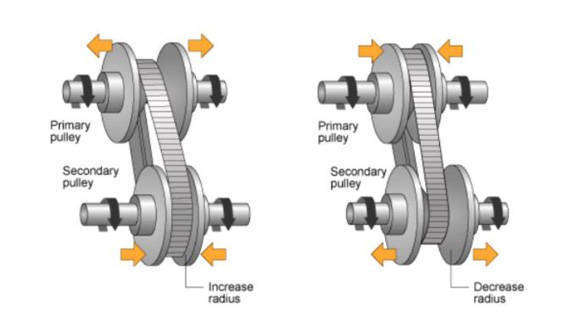

This may be an alternative to having 2 speeds at a ratio amiable to finish speed and coarse speed tumbling. It should be possible to wire this motor with switches to run it at 1140(finishing) and 1740(coarse) with flip of switch. Note amps/hp are lower with the 1140 speed setting for lighter duty finishing speeds. Another air over motor. Hell, all my tumbler motors are air over. For 10 years now.  Side note. Mad Max shopping. Buying motors at the big city metal recycling operations for $2/pound. Movie production companies shop here often for their sets:      My Man Marvin at Star Metals  This is Mid South. I dragged out about 150 pounds of SiC 60 grinding wheels out of this stack for $60.     And about 5 more acres of stuff.... Earl at Mid South salvage  |

|

|

|

Post by captbob on Nov 20, 2019 12:15:15 GMT -5

Doing polish in a rotary tumbler is not a wise thing to attempt, unless you are dry tumbling with corn cob, apparently. wow.... That may be the least true thing I have ever seen posted on this forum in the 12 years that I have been here. There are world class tumblers here that do all their finishing in a vibe. I will happily go up against all of them using a rotary tumbler. (no offense vibe guys!!!) Mine will just take longer. MUCH longer

Never even considered dry polishing. Might be an interesting change of pace with a very few rock types, but it certainly isn't necessary.

|

|

EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Nov 20, 2019 12:51:28 GMT -5

Doing polish in a rotary tumbler is not a wise thing to attempt, unless you are dry tumbling with corn cob, apparently. wow.... That may be the least true thing I have ever seen posted on this forum in the 12 years that I have been here. There are world class tumblers here that do all their finishing in a vibe. I will happily go up against all of them using a rotary tumbler. (no offense vibe guys!!!) Mine will just take longer. MUCH longer

Never even considered dry polishing. Might be an interesting change of pace with a very few rock types, but it certainly isn't necessary.

Just speaking from my own limited experience. I won't try it again lol. They went from nice looking stones to beat up, chipped rocks that I almost couldn't salvage. Of course I was following Thumler's instructions so should have expected as much. |

|

|

|

Post by captbob on Nov 20, 2019 13:11:25 GMT -5

Is there a thread where you posted what you experienced and the steps you used in your failed attempt?

Following Thumler's beginner level instructions was probably the problem...

I would be happy to help ya come out with better results, as "world class" tumbles are quite possible using only a rotary tumbler.

caveat: I can't say (guarantee) that for 3 lb barrels as I have never used a barrel that small.

May be the same, but I wouldn't know.

Just sayin' that great tumbled rocks are just as possible using a rotary only as with using a rotary then finishing in a vibe.

Just takes time

time = patience

Rotary switching to vibe = same results, just faster.

I just don't care that much to worry about how long the rocks take.

Still being new to this, you may want to see the results sooner rather than later.

All good.

|

|

EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Nov 20, 2019 13:36:54 GMT -5

Basically all the steps were the same, just different grit. I wasn't a member of the forum at that time, so there is no thread about it. You're right. The instructions were definitely the problem. I do like how fast and user friendly my Lot O vibe is. I am pretty patient, but obviously you've got me beat in that respect  |

|

|

|

Post by parfive on Nov 20, 2019 13:54:03 GMT -5

KISS Amy - All 3 lb barrels, Thumlers. Model Ts - fast, 50 - 55 rpm - for coarse grind 60/90 Model AR-2 - slower, 32 rpm - for anything else |

|

rockbiter

having dreams about rocks

Member since October 2019

Posts: 60

|

Post by rockbiter on Nov 20, 2019 18:22:05 GMT -5

Holy crap jamesp! Now you're just bragging! Wish I had a place like that to buy used parts around here. That looks awesome! Best option I have here is grabbing stuff from the metal pile at the waste transfer station. Tough to find anything in particular there. I wish I lived where I could just rough tumble outside most of the year, but I only get about two months of frost free weather. And I have limited garage space with too many tools. Makes the whole process of tumbling a lot more difficult and unpleasant. I still don't understand how much current that sewing machine motor will end up drawing, so I ordered one and an energy meter. If the motor uses a lot of power under a small load I will return it. Probably not going to be ideal but I'm very curious. For science! |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Nov 21, 2019 5:55:29 GMT -5

There was not any information on the power usage of that unit rockbiter. I did some searching, was curious. The advertisement was a bit vague. Not sure if that is a DC or AC motor, just a servo motor. Go for it ! Anxious to see your findings. If you bought that unit US made you'd probably pay triple. Some of the oversea products are of very high quality. That unit looks well made. Yep, those industrial junkyards were treasure troves and loaded with stuff to build tumblers. Who builds a tumbler using 1.5 inch solid shafts ! They were cheap at 25 cents per pound. In 10 foot lengths. At first I was going to leave those solid shafts 10 feet long and have only one set of shafts using 4 end bearings since shaft sag was no issue. And use it only for coarse grind with like 8 barrels but changed plans and cut the shafts in half and do 2 sets of shafts with slow/fast. The cost of coarse silicon carbide back then was over $2/pound and it would have cost a lot to run 8 barrels in coarse. Then I found raw silicon carbide for 45 cents/pound and wish that I had made the 10 foot wide coarse grind tumbler. The good old AC motor is going to be hard to beat since it is designed specifically to run directly off of pure 60 hertz AC. With the salvage motors available so cheap I was able to try all kinds of expensive industrial AC motors from 1/12 to 1/2 hp. Expensive motors like TEFC, 1.0 service factor, capacitor start, cooling fins, etc. These ended up being the toughest most efficient motors sized well for tumblers: 1/12 and 1/8 hp air over fan motors could be found removed from A/C roof top units that apparently ran off the 110 VAC control voltage instead of 208/220. Roof tops are big expensive units, last thing they want is a fan motor failure. Trane, Carrier, those guys have their own bad ass motors made specifically for their systems. These 1/12 to 1/8 hp motors were big and heavy. Large in diameter, high in torque. Ran at lower rpm like 840 and 1140 rpm allowing smaller pulleys. I used a current clamp on them and they used the least power per pound of rock. Granted they were air over motors but designed for extra loads like hot air, dirty filters, leaf obstructions, bird's nests, etc. Had open cage for cooling. Fine for conservatively loaded tumbler. If doing it all over again I would build several tumblers using these 1/8 hp motors and roll two 15 pound or three 12 pound barrels on each of them instead of the one big tumbler with 1/3-1/2 hp. More diversity that way. Take a breather and run less barrels for a spell. Or go rock hunting and bring home a mother load and want to run 100+ pounds. |

|

|

|

Post by 1dave on Nov 21, 2019 11:13:22 GMT -5

Good advice from jamesp! " If doing it all over again I would build several tumblers using these 1/8 hp motors and roll two 15 pound or three 12 pound barrels on each of them instead of the one big tumbler with 1/3-1/2 hp. More diversity that way. Take a breather and run less barrels for a spell. Or go rock hunting and bring home a mother load and want to run 100+ pounds." Read more: forum.rocktumblinghobby.com/thread/89489/variable-speed-motor-tumbler#ixzz65vg5vKMH  |

|

rockbiter

having dreams about rocks

Member since October 2019

Posts: 60

|

Post by rockbiter on Nov 21, 2019 21:25:29 GMT -5

jamesp I'm sure you have said elsewhere, but where do you get your rough grit? I bought 10 lbs of 30 grit but that isn't going to last long if I actually ever get this tumbler completed. Also, an old post talked about using 220 AO as the only step between rough grind and polish. Newer threads I don't see you recommending that. Does that work well? I bought some 220 AO from a sandblasting company.

|

|

EricD

Cave Dweller  High in the Mountains

High in the Mountains

Member since November 2019

Posts: 1,142

|

Post by EricD on Nov 21, 2019 21:34:22 GMT -5

jamesp I'm sure you have said elsewhere, but where do you get your rough grit? I bought 10 lbs of 30 grit but that isn't going to last long if I actually ever get this tumbler completed. Also, an old post talked about using 220 AO as the only step between rough grind and polish. Newer threads I don't see you recommending that. Does that work well? I bought some 220 AO from a sandblasting company.

He's got almost any grit you could need in AO and SiC.

220 AO works great in a vibe after shaping in the rotary. If you're doing the 220 in a rotary I have no idea.

|

|

|

|

Post by TheRock on Nov 22, 2019 5:11:59 GMT -5

This is a great thread. Different speeds for coarse and finishing steps is all good. Certainly a forward move.  Note slurry paint job on open cage motor. No ill effects so far but it will EAT bearings. Had to post this for TheRock Bob in light of his totally awesome pristine shop. Dammit Bob rock tumbling is just a nasty operation. I do keep the insides of those barrels well maintained. It's all about the rocks ! About 200 sq ft of the gravel floor is now concreted together with rock slurry. Man that slurry makes fine Portland. The vibe is kept a distance away in much neater/cleaner conditions.  WoW.... yeah I have to agree this is a good thread. James I may have a pristine shop but some days I'm feelin ole rusty and crusty like some of yer tumblers! Anyways I was off of here for a couple days and had some Catchin up to do on this Post. Well rockbiter in my 40+ years working on HVAC Equipment. I have to agree with what jamesp said the War of A/C and D/C was fought years ago between Edison & Tesla and Tesla won that battle. I will stick with my A/C Electric. As nik mentioned the theory of brushes and commutators burning up, and for that reason I have to back away. Something running 24/7 365 I am afraid it will fail, and you will be lucky not to burn a Com and if that happens you might as well pack it in and buy a new motor. At the beginning of this post I gave you my honest opinion on the way I would go and that would be a VFD. At my last Job at Berrien County I wore two hats Mechanical Systems Manager, and Jail Maintenance Supervisor. And for that matter all of my staff maintained all the buildings in Berrien County. We had many VFD's on all our Big Air Handlers. The Largest probably being I think 30 HP 460V 3 Phase motor. They were all Belt Drive and Used a Set of 6 Matched Belts. Those Belts were LONG and when You replaced 1 you normally had to do them all, because they were a matched set. you would play hell just buying a couple that broke and getting them to be the same length because of wear Belts stretch with age and a set of belts like that cost over $300.00 for the set. A VFD starts the motor S L O W L Y which turns The Huge Squirrel Cage Fan 12' High anyway it starts slow as not to burn the belts. That was one benefit of using VFD's but the most benefit was the ability of having the choice of infinite speeds depending on the load or loss in HVAC. In other words on a really cold day may require alot of generated heat and would require maybe a larger amount of CFM to push the heat. Anyway that's the biggest benefit of building a tumbler with a VFD system is the ability to having infinite speeds available with the turn of a dial and having the ability of being able to reverse the direction of the barrel and for the cost of less than $300.00 and with the ability for all that it can do, I pulled the trigger and got all the GROCERIES below. I Just recived a Used Baldor 3PH 220V 1/2hp 1725 RPM Motor, A Automation Direct GS1 VFD and the Computer Interface Cable Package. I wont get to building this tumbler until spring or summer but getting some of the goodies never hurts.   |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Nov 22, 2019 5:53:53 GMT -5

jamesp I'm sure you have said elsewhere, but where do you get your rough grit? I bought 10 lbs of 30 grit but that isn't going to last long if I actually ever get this tumbler completed. Also, an old post talked about using 220 AO as the only step between rough grind and polish. Newer threads I don't see you recommending that. Does that work well? I bought some 220 AO from a sandblasting company. Steering away from the subject VRD's here, but your coarse grind is the most expensive and timely step in tumbling. Varying speed ain't going to speed your tumble much. But aggressive coarse grit and good slurry sure will. Yes, I added a silicon carbide 500 step after coarse grind when I began using "metallurgical grade silicon carbide". Best thing I ever did. I did research on cheap silicon carbides. I found a raw ungraded metallurgical grade SiC that is only 90% pure SiC used in the steel industry. Not for abrasive use. Instead of paying $2/pound for SiC 30 I only payed 45 cents/pound for 750 pounds of the metallurgical grade. It works fine since coarse tumbling is such a crude abrasive process, target is simply to shape rocks. The SiC 500 does a fine job of prepping the rocks for AO 220 after the raw SiC has butchered them. So the added step. The old recipe was: SiC 30 rotary w/clay with the last SiC 30 addition run for 10 days to break the SiC 30 down to ~SiC 500 to SiC 1000 AO 220 Vibe w/sugar AO 14,000 Vibe w/sugar The new recipe is: Raw "metallurgical grade SiC" rotary w/clay SiC 500 rotary w/clay AO 220 Vibe w/sugar AO 14,000 w/sugar The raw SiC was by far the single most money saver when tumbling large amounts of rocks. BUT, it forced me to find abrasive resistant barrels - the HDPE barrels. If it wears your barrels fast then it is wearing your rocks fast ! |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,606

|

Post by jamesp on Nov 22, 2019 6:01:23 GMT -5

jamesp I'm sure you have said elsewhere, but where do you get your rough grit? I bought 10 lbs of 30 grit but that isn't going to last long if I actually ever get this tumbler completed. Also, an old post talked about using 220 AO as the only step between rough grind and polish. Newer threads I don't see you recommending that. Does that work well? I bought some 220 AO from a sandblasting company. He's got almost any grit you could need in AO and SiC.

220 AO works great in a vibe after shaping in the rotary. If you're doing the 220 in a rotary I have no idea.

I ran AO 500 and AO 1000 and AO 14,000 in a rotary. AO 24, AO 46, and AO 80 was useless in the rotary, doable in a powerful vibe but not effective excepting AO 80 for hard rock in a powerful vibe.. The Abrasive Armory is the best place to buy AO 80, AO 220, probably AO 500. I have used 3 to 4 sources for buying AO 80 and AO 220. From sand blasting grade to high quality screened AO(for precision finishes) suppliers. They all worked the same(in my vibe). |

|