|

|

Post by MrP on Feb 24, 2020 9:17:02 GMT -5

Ultrasonic drill is the way to go. Just finished drilling 1.5mm holes in 250-300 pair of glass earrings. I cut the glass from left over scrap then fire polish and drill for earrings. It took 6 1.5 mm needles to do all the holes at a cost of less then a penny a needle. If every thing is working right with the drill it is much faster then a diamond drill bit. It does take some time to figure out how to get the ultrasonic set up right. When it is right it is great but if not right it is a pain in the butt....................MrP Fire polished earrings  Drilled earrings  |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,608

|

Post by jamesp on Feb 24, 2020 9:46:01 GMT -5

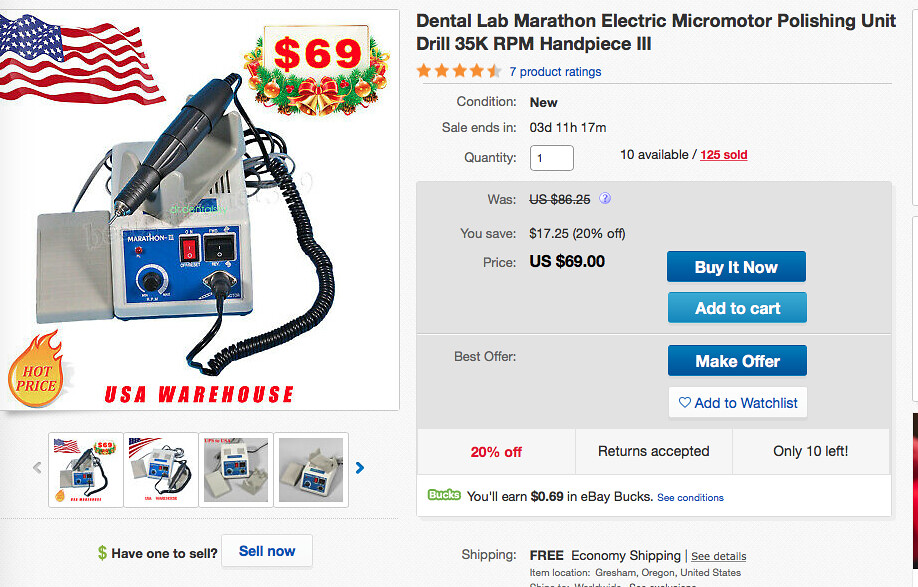

Ultrasonic drill is the way to go. Just finished drilling 1.5mm holes in 250-300 pair of glass earrings. I cut the glass from left over scrap then fire polish and drill for earrings. It took 6 1.5 mm needles to do all the holes at a cost of less then a penny a needle. If every thing is working right with the drill it is much faster then a diamond drill bit. It does take some time to figure out how to get the ultrasonic set up right. When it is right it is great but if not right it is a pain in the butt....................MrP This is valuable info Michael. Thanks. You are talking about the type of production rates I am interested in. Curious about your machine. Cost/brand/etc. I found this bare bones ultrasonic machine on EBAY. Looks raw but has the ultrasonic generator and control box. Not bad for price:  |

|

|

|

Post by MrP on Feb 24, 2020 12:19:00 GMT -5

jamesp I bought my drill used off of craigslist. I was given the name of a person who had a ultrasonic drill and it turned out she had just sold it the week before. I talked to her about the cost of the drill and using it. I think she had paid $3000 for it and sold it for $1200 or $1500. Wasn't worth that kind of money to me so I kept looking and found one very cheap on craigslist. Turned out it was junk but only gave $75 so no big deal. Not too long after that the one I have now showed up on craigslist for $1400, month or so later it was $900. Month or so later $800 so I called to go look at it. He could not get it to drill right so people who showed up did not buy it. I offered. I think, $250 but had to end up paying $275. Turned out it was the one I had called the other person on a year before. I almost gave up on learning to use it because there is a huge learning curve to it. There was not much info on the internet on how to use one. The person who bought it new said that when it is working right you will love it but if it is not working right you will wish you had never seen it. She was right! I found this one Drill for $1600. Not sure how the $600 one you found, compares too the one I have but, many times you get what you pay for. Keep in mind you will need more drill cones or you will always be soldering new drill tips on. That is another problem, silver soldering the tips on. They have to be straight and a very good solder job. The cone has to be for the machine you have because it has to have the right shape and length to get the waves at the drill tip. My drill was bought new at my drill . I have not contacted them for 3-4 years so am not sure if Bill is still there. I bought my silver solder and drill tips from him. Had to buy a few hundred tips at a time but they were very cheap at that time. Good Luck...................MrP

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,608

|

Post by jamesp on Feb 26, 2020 10:23:37 GMT -5

Thanks MrP. Was late seeing your valuable reply. Thanks. Lots of great information you have given. So this machine requires added skills. I can now see why these machines could be had cheap due to some of the needed skills in setting them up. I am going to try ball end dental bits first. If that is difficult or slow going I may purchase the $600 unit posted above. Your machine looks quite a bit more robust than the EBAY unit. Your post sheds more light on this ultrasonic route. However I am generating a lot of glass and would like to drill small holes 1/2" to 1" as a beading process would require. Ultrasound is the only way to do such. |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,608

|

Post by jamesp on Feb 27, 2020 12:45:16 GMT -5

I just drilled a few .5mm and 1.5mm holes at 35,000 rpm using solid bits using this new machine. 1.5mm holes took only 4 to 5 seconds but still had blowout issues. But way reduced drilling pressure making much smaller blow outs. 8000 rpm 2.5mm hollow core bit holes took 30 seconds using Rio Grande drill press. More drilling pressure along with bigger blow outs, more breakage. WOW, what an improvement. I say it is all about moving from 8000 rpm to 35,000 rpm. And having shorter 1 inch long X 1.6mm shaft diamond bits the spin very true, without wobble. Simply twist drill motor to unlock bit, replace bit, twist it again to clamp bit. This drill motor only accepts 1.6mm diamond bit shafts(as used in dental drill diamond bits). Guessing the Ultrasonic machine has even better performance but this machine may be enough for my glass. This machine(only accepts 1.6mm drill bit shafts...):  |

|