|

|

Post by Rockoonz on Mar 29, 2020 12:57:34 GMT -5

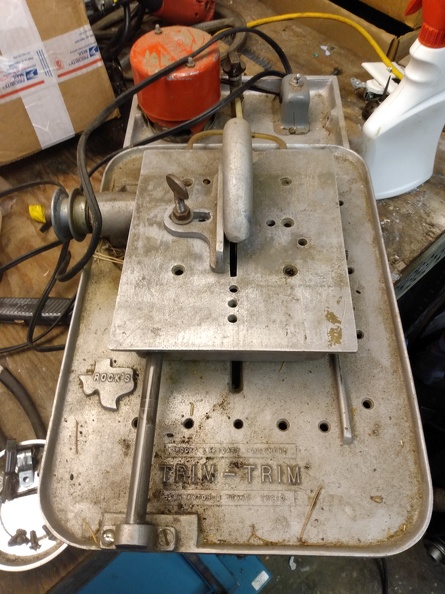

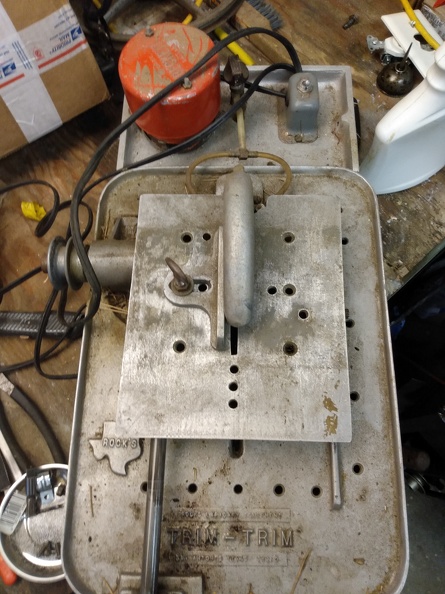

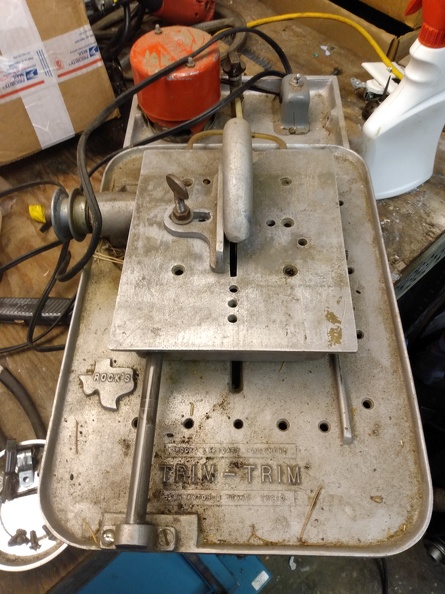

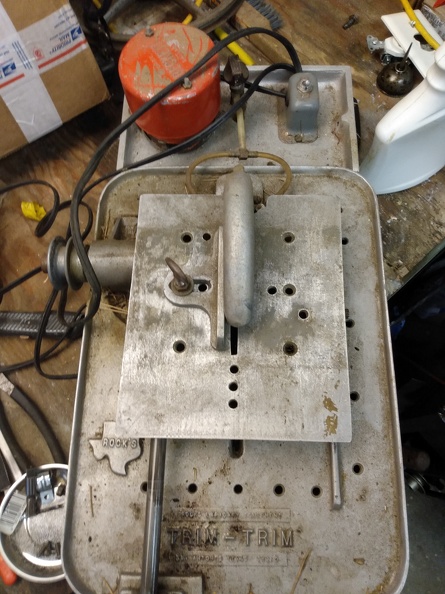

roy catmandewe NRG jamesp TheRock and whoever else I forgot to tag. Here's one that has been sitting in the shed waiting for me to get to it for awhile. Paid more than I should have on ebay several years ago because I had to have it, now I have some time on my cabin bound weekends and it's on the bench. It was marketed as a "safe saw" since it has the sliding slab platform, I got it because of the adjustable fence to cut uniform intarsia pieces easily.  As I will show below, it has a deep sump with a recirculating pump, which brings me to my first question. Do I have to use oil, or will water with additive be okay for the pump? The pump spins, haven't put liquid in to test yet, maybe later today.   I don't like the switch location, it will be moved and wiring with a ground wire added, possibly an inline gfci if I use water, the large sump makes this a production machine, so things may get messy. I plan to build a stand for this with the motor below, but I will probably screw it to the workbench with a motor behind it first to try it out and see how wet things get. For sure I need a wash down motor or at least farm duty. The whole thing needs to be power washer friendly, I have the sealed switch already.  Any ideas regarding the plan?

|

|

|

|

Post by catmandewe on Mar 29, 2020 13:07:15 GMT -5

That switch is designed to mount on your motor, it replaces the cover plate in the wiring compartment.

Tony

|

|

|

|

Post by mohs on Mar 29, 2020 13:13:19 GMT -5

Of coarse no refurbish suggestions Lee my brain really perked up when you mentioned intarsia sluced pieces looks like a smmmoooooth slicer hope your travel plans are moving smooth, too and have saw will travel  |

|

|

|

Post by Rockoonz on Mar 29, 2020 16:08:41 GMT -5

That switch is designed to mount on your motor, it replaces the cover plate in the wiring compartment. Tony I noticed that. It will go into my parts bin for a future project, those switch covers are hard to find, unless maybe you have a source. |

|

|

|

Post by TheRock on Mar 29, 2020 16:42:13 GMT -5

Well Deep Sump Wow I'm drooling And you know what I am thinking! And I cant say enough Good about the Everclean And this saw looks like the perfect canidate. But I know how much you don't like the BROTHERS GRIM so I will get off of that.  This article I posted a couple days ago may shed some light. Blade Choosing Article The best thing to use on any saw, except a spindly tile saw saw is oil. But for a trim saw water is always the choice. So I would vote on oil to make the blade last that saw looks like a 10" or 12". I used a Harbor Freight Cart Like This one to mount BD SAW on and on two years of usage now and I haven't looked back and was a great move. Like you my sump is located down below on the bottom shelf and even if you don't do the everclean unit you need to make a easily removable screen box that will catch large rock chips from bucking up your pump. Or you can set your pump down in a screened in compartment to protect it from rock chips. Pipe your pump with hose that resists oil like a hydraulic hose go to your local industrial supply. To buy your hose and Barbed Fittings. Yep relocating the switch and GFCI is a good thing even using oil. An ounce of prevention is worth a pound of cure. Looking at your saw it doesn't appear to be auto feed and I was going to mention a hood like is on the BD but no since in doing that Unless it's auto feed. But if you need measurements on hood or anything let me know. Anyway good Luck looks like a nice project and really like the saw as it looks well built. Harbor Freight Polypropylene Service Cart |

|

NRG

fully equipped rock polisher

Member since February 2018

Posts: 1,688

|

Post by NRG on Mar 29, 2020 17:20:44 GMT -5

Hi Lee,

A couple years ago, Diamond Pacific introduced a new blade called "agate kutter" and is/was designed to be used exactly in this setting with water.

I have cut with this blade and it worked very well. I do not know if it is still available.

|

|

|

|

Post by aDave on Mar 29, 2020 18:37:13 GMT -5

Hi Lee, A couple years ago, Diamond Pacific introduced a new blade called "agate kutter" and is/was designed to be used exactly in this setting with water. I have cut with this blade and it worked very well. I do not know if it is still available. Looks like they are still available, as (at least) Kingsley North sells them. Interestingly, the site indicates the Agate Kutter blade is meant for high speed water cooled saws and not for saws running at 1725. I recalled seeing this thread a couple of years ago in which johnjsgems said the MK225 blade was formerly marketed as the Agate Kutter. forum.rocktumblinghobby.com/thread/78026/tile-bladeIf they are close, performance-wise, the MK225 might be an option as pricing is much better. Coincidentally, I have 2 new ones in the garage, but I haven't had a chance to use them yet. |

|

|

|

Post by TheRock on Mar 29, 2020 21:41:17 GMT -5

That switch is designed to mount on your motor, it replaces the cover plate in the wiring compartment. Tony I noticed that. It will go into my parts bin for a future project, those switch covers are hard to find, unless maybe you have a source. Here Ya Go Lee. LINK TO SWITCH COVER |

|

|

|

Post by TheRock on Mar 29, 2020 21:46:36 GMT -5

You can Use Water But You will replace a Blade More Often. At the point of contact with the Blade to the Rock, the heat builds up, and for an instant, the water flashes to steam, which doesn’t carry the heat away. Most blade manufacturers do not recommend using water because it causes premature blade wear. However, many people prefer the easy cleanup of water, and with it, they endure the need for more frequent blade replacements.  |

|

|

|

Post by Rockoonz on Mar 29, 2020 23:09:08 GMT -5

Well Deep Sump Wow I'm drooling And you know what I am thinking! And I cant say enough Good about the Everclean And this saw looks like the perfect canidate. But I know how much you don't like the BROTHERS GRIM so I will get off of that.  This article I posted a couple days ago may shed some light. Blade Choosing Article The best thing to use on any saw, except a spindly tile saw saw is oil. But for a trim saw water is always the choice. So I would vote on oil to make the blade last that saw looks like a 10" or 12". I used a Harbor Freight Cart Like This one to mount BD SAW on and on two years of usage now and I haven't looked back and was a great move. Like you my sump is located down below on the bottom shelf and even if you don't do the everclean unit you need to make a easily removable screen box that will catch large rock chips from bucking up your pump. Or you can set your pump down in a screened in compartment to protect it from rock chips. Pipe your pump with hose that resists oil like a hydraulic hose go to your local industrial supply. To buy your hose and Barbed Fittings. Yep relocating the switch and GFCI is a good thing even using oil. An ounce of prevention is worth a pound of cure. Looking at your saw it doesn't appear to be auto feed and I was going to mention a hood like is on the BD but no since in doing that Unless it's auto feed. But if you need measurements on hood or anything let me know. Anyway good Luck looks like a nice project and really like the saw as it looks well built. Harbor Freight Polypropylene Service CartIt's only a lil ol 6" saw, but the sump is 9 1/2 x 18. Only thing I would use it for is trimming, if I want to hand cut small stuff I have another saw for that. A screen baffle is a great idea, I'll definitely make one for around the pickup. |

|

|

|

Post by TheRock on Mar 29, 2020 23:15:26 GMT -5

Well if only a trim saw w a 6" Blade I would go water. Id buy a BD301 Blade for it. The Agate blade is made for a 10" and larger saws. Just dry and spray the arbor when finished.  |

|

|

|

Post by Rockoonz on Mar 29, 2020 23:15:56 GMT -5

I noticed that. It will go into my parts bin for a future project, those switch covers are hard to find, unless maybe you have a source. Here Ya Go Lee. LINK TO SWITCH COVER Bad terminology on my part, what I would like to be able to get is the stamped steel motor wiring covers to mount switches directly to the motors for cleaner wiring. This is what I'm doing now, works ok but not as nice as the little cover IMO.  |

|

|

|

Post by aDave on Mar 30, 2020 2:31:05 GMT -5

Well if only a trim saw w a 6" Blade I would go water. Id buy a BD301 Blade for it. The Agate blade is made for a 10" and larger saws. Just dry and spray the arbor when finished.  Bob, it would seem the Agate Kutter blade ranges in size from 5" ro 14". kingsleynorth.com/agate-kutter-diamond-blade.html |

|

|

|

Post by Peruano on Mar 30, 2020 8:30:33 GMT -5

If one of your worries was using water in that pump, I'd guess that the pump won't care whether it moves water or oil (and actually might find oil less of a strain for the pump).

As some will possibly recall I'm a major fan of the MK 225 (I use a 12" on a slab saw and bought a 10" to use on an HP saw). One potential concern for using this blade on a hand fed saw is chipping for some softer and more valuable materials and the slots in the perimeter as a danger to fingers if material is handheld. Chipping might occur if the feed was not slow and steady like a slab saw. But you are using the vice and sled, and shouldn't have finger worries. I'm still assuming the 225 is the same as the Agate Cutter as originally noted by John's Gems.

No one has ever stated it as a rule, but in the 301, 302 series only the bigger blades have the slots (slab saw application? or just better oil carrying capacity); and the smaller sizes are almost never slotted (but tile saw blades often are). Are tile guys fingers less valuable or better protected, or do they need the carrying capacity for coolants due to higher rpms.

Sorry to lead the discussion astray. Curious minds want to know.

|

|

AzRockGeek

has rocks in the head

Member since September 2016

Posts: 703

|

Post by AzRockGeek on Mar 30, 2020 8:56:45 GMT -5

Is this the type of cover you are looking for, like the one on your pump?  |

|

|

|

Post by Rockoonz on Mar 30, 2020 9:04:16 GMT -5

Is this the type of cover you are looking for, like the one on your pump?  Yes, exactly what I need. |

|

AzRockGeek

has rocks in the head

Member since September 2016

Posts: 703

|

Post by AzRockGeek on Mar 30, 2020 9:23:58 GMT -5

How many do you need? I have few laying around.

|

|

|

|

Post by Rockoonz on Mar 30, 2020 9:41:25 GMT -5

How many do you need? I have few laying around. I will take as many as you want to sell. Better would be if one has a tag inside with a part number so I can look for more. I restore equipment so I get lots of new motors, 5 so far this year. |

|

AzRockGeek

has rocks in the head

Member since September 2016

Posts: 703

|

Post by AzRockGeek on Mar 30, 2020 10:37:55 GMT -5

I spent 45min on google to find a source, complete strike out. This is a job for rockpickerforever . |

|

|

|

Post by rockpickerforever on Mar 30, 2020 18:47:21 GMT -5

I spent 45min on google to find a source, complete strike out. This is a job for rockpickerforever . Thanks for the vote of confidence, Tim.

Is Lee looking for a switch, a switch cover or what? I understand it is a switchbox to mount a switch "cleanly" to a motor.

I can't see the photo. If you can reload it, I'll do some hunting for you.

Jean

|

|

This article I posted a couple days ago may shed some light.

This article I posted a couple days ago may shed some light.