Complete tutorial to wire wrapping (58 pics)

Dec 7, 2008 12:37:03 GMT -5

Fossilman, MoonRock, and 5 more like this

Post by Bikerrandy on Dec 7, 2008 12:37:03 GMT -5

ADMIN EDIT - fixed all 58 broken images

----------------------------

Alrighty, see if I can do this without confusing anyone....and myself. ;D First- if I miss anything or you have any questions, please ask!! I have attempted to go as far as possible into detail, but being brain damaged I tend to forget stuff. Also, I would like this to be a running post. Everyone has different secrets and techniques (Dee)

Also, I would like this to be a running post. Everyone has different secrets and techniques (Dee)  , and I want to see all of them!! (open invitation for a highjack, yes, highjacking is welcome) Basically, this is how "I" do it, start to finish. First you'll need some tools. I use a pair of flat nosed pliers, needle nosed pliers, side cutting pliers, front cutting pliers, and round nosed pliers.......

, and I want to see all of them!! (open invitation for a highjack, yes, highjacking is welcome) Basically, this is how "I" do it, start to finish. First you'll need some tools. I use a pair of flat nosed pliers, needle nosed pliers, side cutting pliers, front cutting pliers, and round nosed pliers.......

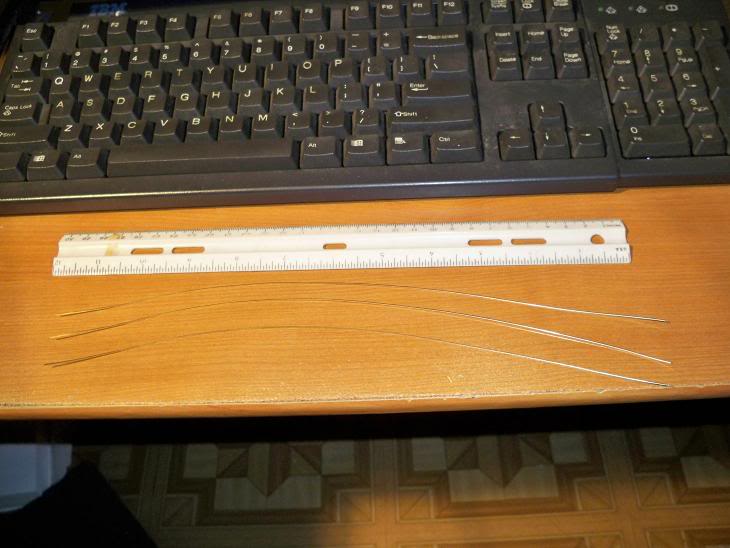

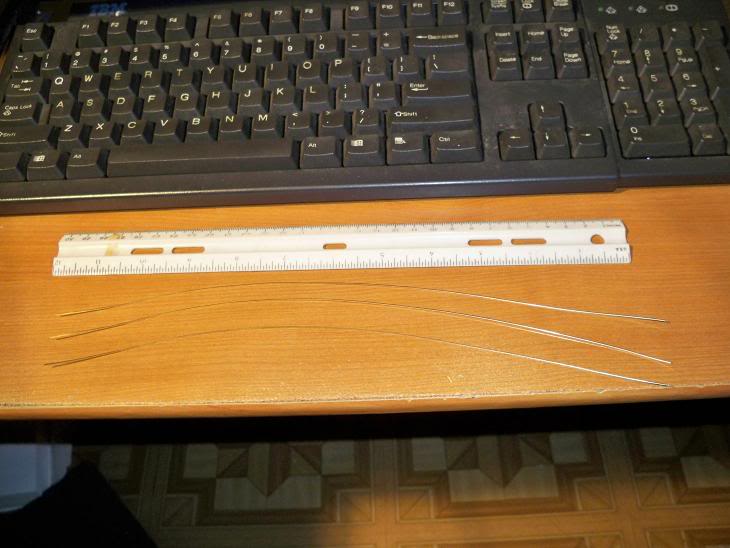

Next, you need wire and some masking tape. I use 22 gauge square wire, gold filled "dead soft" and for the binding wraps I use 21 gauge half-round, half hard wire, gold filled. I get all of my wire from Rio Grande. Trust me on this, from these guys you'll get the most for your money!!

NOTE: for beginners get the copper wire from Brandywine.... www.brandywinejewelrysupply.com/wire/

First, cut three strands of the square wire about ten inches long each......

Next, you need masking tape. I always have mine cut in strips, "ready to go". Four strips will do the job.....

This will keep your wire in a straight uniform line. In order for your wire wraps the look clean, the wire will remain in the same order throughtout the entire process!!

Notice that I didn't place the tape exactly in the center of my 10 inch strands. There's a reason I did this (I figured this one out just 2 days ago) and you'll see why as we go.......

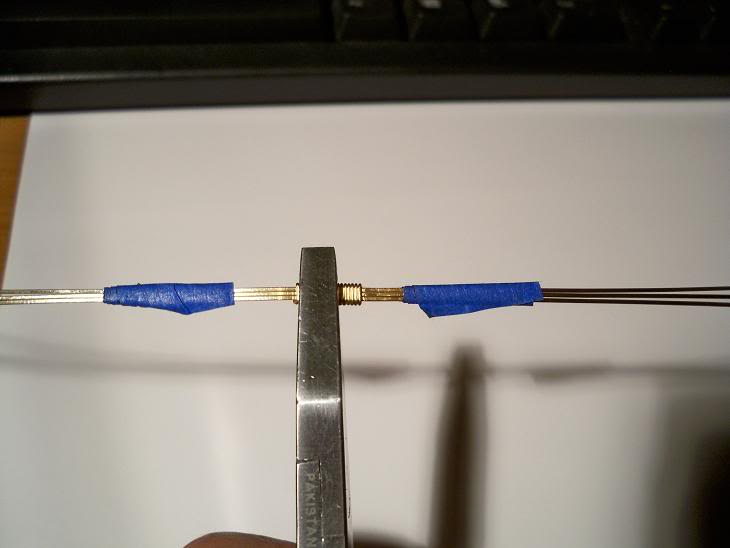

Next, cut a piece of the binding wire (21 gauge half-round) about 6 inches long.....

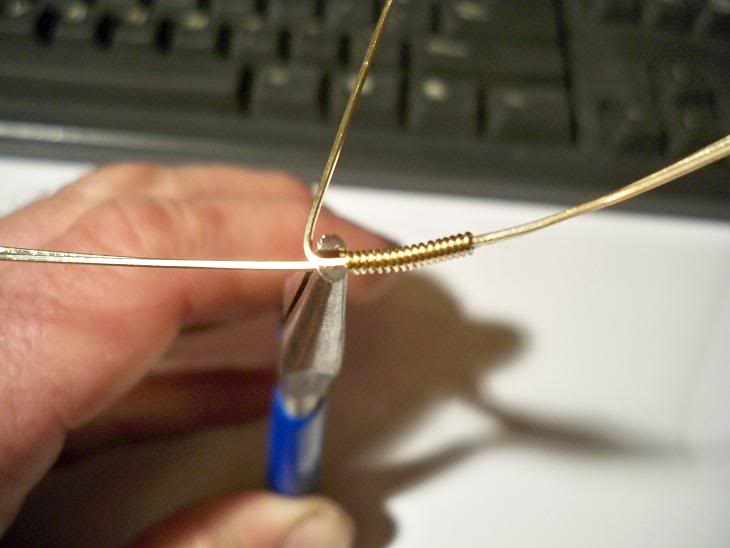

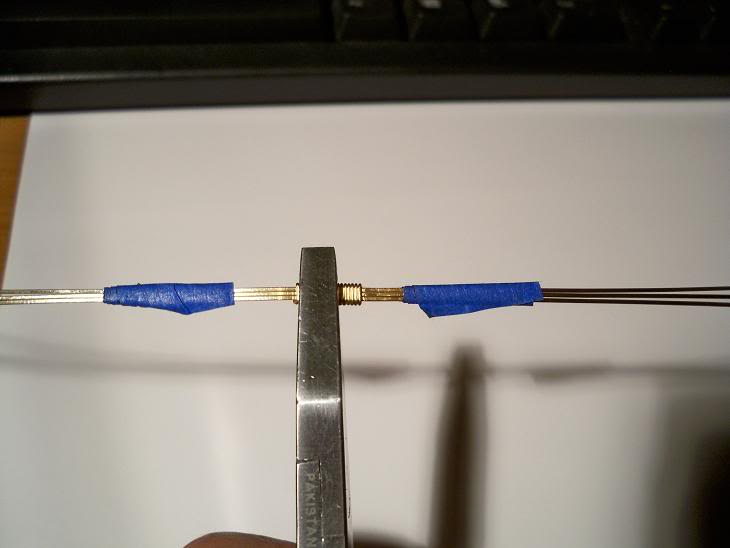

Now we're ready to start wrapping. It's important to go slow, keeping the wraps tight and uniform. Uneven bindings will make your work of art look like the work of a madman with wire ;D The ends of the binding wire can be tweaked after you get the on...

Cut them as close to the wrap as you can, and remember that the cuts will be to the inside of the wrap when finished.

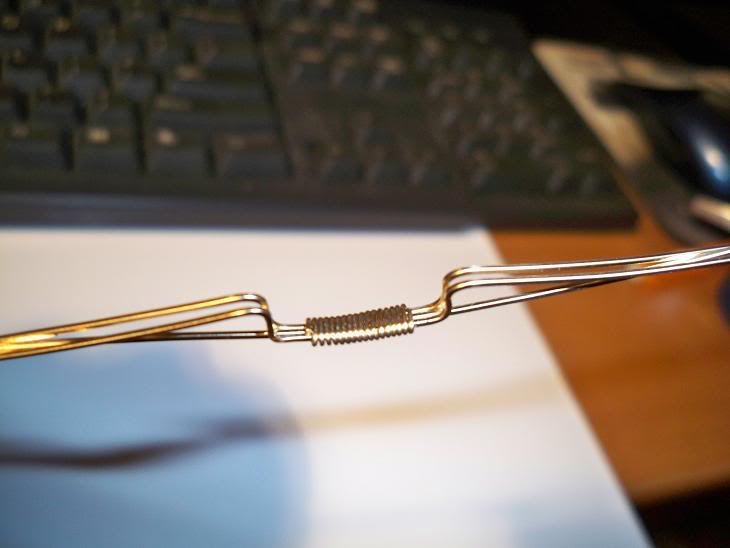

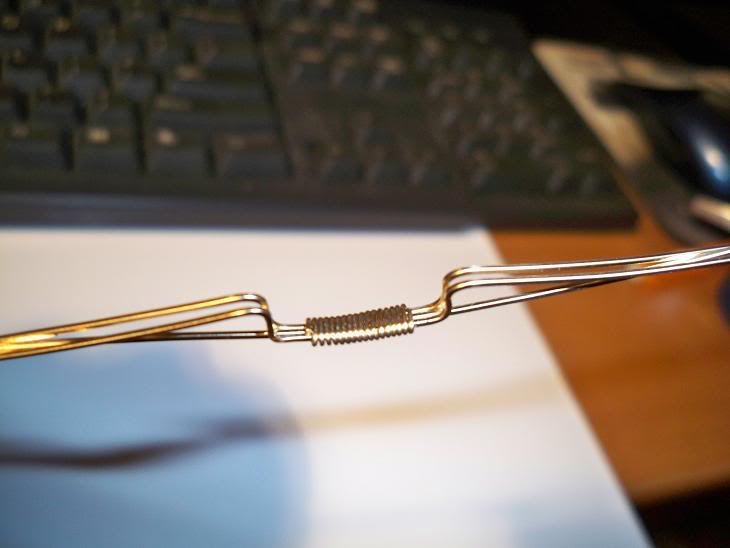

When finished (after some tweaking), it should look clean

Now it's time for the flat-nosed pliers. Some people wrap the nose with masking tape to keep from marring the surface of the wire. I'm hard core ;D haha...... with these you'll gently crimp the binding......

A good crimp should look like this....

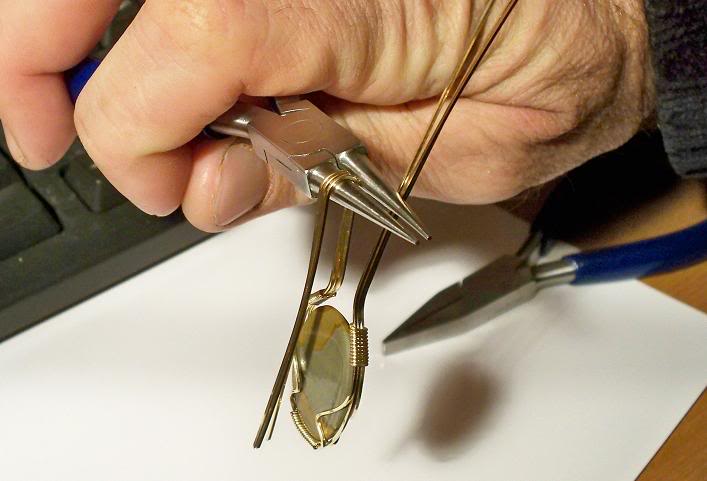

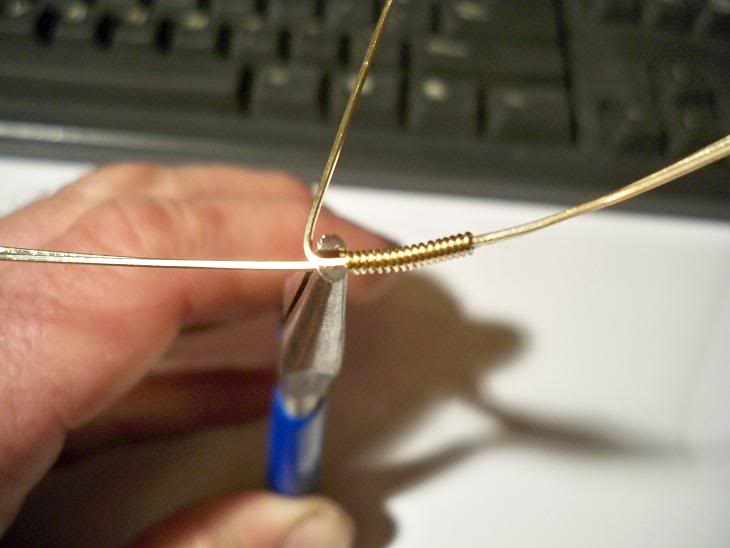

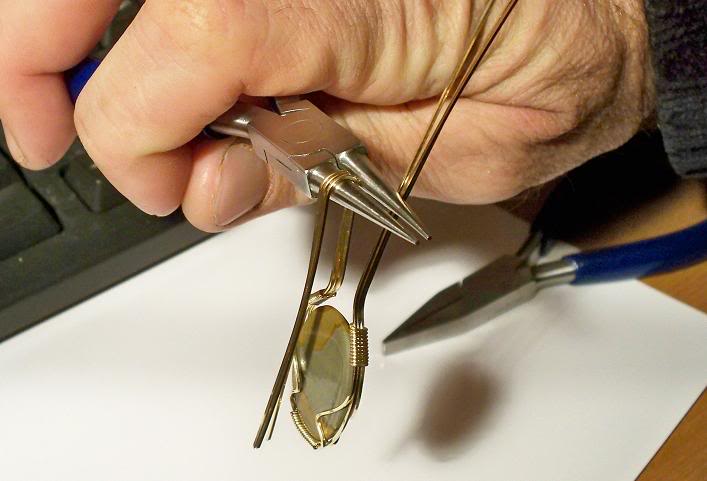

Now the fun stuff, bending the wire (bail). Here we'll use the needle-nosed pliers to get the proper bends. Once again, some people wrap the nose with masking tape. Did I mention that I'm hard core? Oh, the pliers ...... Notice that I place the tip of the pliers tight against the binding wrap

...... Notice that I place the tip of the pliers tight against the binding wrap

The first bend will be made here

Next, my second bend is made here, keeping the nose of the pliers tight against the first bend....

Repeat on the other side of the binding wrap....

Next, flip the wrap over and repeat with the other side. When finished, you'll have four uniformed bends (both sides of binding wire and both sides of the wrap).....

This is where the next two pieces of tape come in. These will be needed to once again keep everything in line while doing the next 2 bindings. The middle wire must always stay in the middle....

After repeating the process of the bindings, you should end up with this. Note that the binding wraps are fairly uniform. As long as you don't crimp them too tight, they will still be adjustable (moveable). Both sides of the bail should look even after all of the adjusting is done. If you look closely, I haven't done any adjusting here. Both sides are "fairly" even, but not perfect (yet).

For the next step we use the flat nosed pliers again. Here we need to spread the wrap apart so that the cab may be inserted....

Now we can start working the wrap around the cab. The cab that I'm using for this wrap is 18mm x 25mm.....

In this pic, note that I did some adjusting on the two bindings on the sides so they are more uniform. It's starting to look like a wire wrap! ...

In this pic you can see where the one side has the long end and the other is short. The long end will be reserved for your swirls....

The short end is for your bail, here you'll use the round-nosed pliers to do the bending. I did my bend exactly 23mm from the top of the cab, or 7/8"......

Note that my wires are still in a straight line, same order as when I started....

Time for the next binding, this is where everything will start to come together. I start mine between the wires as shown because I don't crimp this binding and this will keep the binding from unwrapping. Again, these should be tight and uniform...

At the bottom, I tuck the wire through the wrap at the top of the cab and pull it through tightly. When cutting the ends off, I use the front cutters. Cut as close to the wrap as you can, but be very careful not to cut anything else. One thing that helps me is reading glasses and alot of light.

Using the front cutters (or side cutters if you're more comfortable), you can trim the ends of the loop wires to whatever length you want. I cut mine at different lengths for a desired effect.....

Next, round nosed pliers- use these to bend them however you want

I did mine like this

Nothing left now but to do the swirley thingys. A little creativity will make set your wrap apart from anyone elses. One thing that helps me is drawing pics. I use pencil and paper, and even Microsoft paint. You high-tech rednecks can even use Photoshop.

I do mine one wire at a time, keeping each wire as uniform as possible. Each step will require more tweaking....

Once you get this far, your wires will require some tweaking to look clean and even more uniform.

Time for another binding. Note that all of the wires are still in the same order. This binding is tricky, it's like sewing with needle and thread. Be careful not to kink the wire when pulling it through, just take it slow and pull tightly after each turn. Note that I wrapped a piece of tape around the ends of the wires...

It should look clean and tight, just like everything so far. Note that these don't get crimped either, so they must be tight in order to keep the wires from slipping around.....

After a little more tweaking on the swirls....

Using the flat nosed pliers, you can split up the loops.....

I trimmed these up a little for another one of my desired effects using the front cutters.....

Finally, with a little bending from the round-nosed pliers and VOILA!!!......

Nancy darlin, this one's for you .....

.....

Like I said before, feel free to ask many questions, add remarks, techniques, ideas, pics of ideas...... Just don't throw anything at me. ;D Best of luck to anyone for this challenge, I hope that this makes it easier and answers a few mysteries as well. Next we'll learn how to custom paint a Harley.

----------------------------

Alrighty, see if I can do this without confusing anyone....and myself. ;D First- if I miss anything or you have any questions, please ask!! I have attempted to go as far as possible into detail, but being brain damaged I tend to forget stuff.

Also, I would like this to be a running post. Everyone has different secrets and techniques (Dee)

Also, I would like this to be a running post. Everyone has different secrets and techniques (Dee)  , and I want to see all of them!! (open invitation for a highjack, yes, highjacking is welcome) Basically, this is how "I" do it, start to finish. First you'll need some tools. I use a pair of flat nosed pliers, needle nosed pliers, side cutting pliers, front cutting pliers, and round nosed pliers.......

, and I want to see all of them!! (open invitation for a highjack, yes, highjacking is welcome) Basically, this is how "I" do it, start to finish. First you'll need some tools. I use a pair of flat nosed pliers, needle nosed pliers, side cutting pliers, front cutting pliers, and round nosed pliers.......

Next, you need wire and some masking tape. I use 22 gauge square wire, gold filled "dead soft" and for the binding wraps I use 21 gauge half-round, half hard wire, gold filled. I get all of my wire from Rio Grande. Trust me on this, from these guys you'll get the most for your money!!

NOTE: for beginners get the copper wire from Brandywine.... www.brandywinejewelrysupply.com/wire/

First, cut three strands of the square wire about ten inches long each......

Next, you need masking tape. I always have mine cut in strips, "ready to go". Four strips will do the job.....

This will keep your wire in a straight uniform line. In order for your wire wraps the look clean, the wire will remain in the same order throughtout the entire process!!

Notice that I didn't place the tape exactly in the center of my 10 inch strands. There's a reason I did this (I figured this one out just 2 days ago) and you'll see why as we go.......

Next, cut a piece of the binding wire (21 gauge half-round) about 6 inches long.....

Now we're ready to start wrapping. It's important to go slow, keeping the wraps tight and uniform. Uneven bindings will make your work of art look like the work of a madman with wire ;D The ends of the binding wire can be tweaked after you get the on...

Cut them as close to the wrap as you can, and remember that the cuts will be to the inside of the wrap when finished.

When finished (after some tweaking), it should look clean

Now it's time for the flat-nosed pliers. Some people wrap the nose with masking tape to keep from marring the surface of the wire. I'm hard core ;D haha...... with these you'll gently crimp the binding......

A good crimp should look like this....

Now the fun stuff, bending the wire (bail). Here we'll use the needle-nosed pliers to get the proper bends. Once again, some people wrap the nose with masking tape. Did I mention that I'm hard core? Oh, the pliers

...... Notice that I place the tip of the pliers tight against the binding wrap

...... Notice that I place the tip of the pliers tight against the binding wrap

The first bend will be made here

Next, my second bend is made here, keeping the nose of the pliers tight against the first bend....

Repeat on the other side of the binding wrap....

Next, flip the wrap over and repeat with the other side. When finished, you'll have four uniformed bends (both sides of binding wire and both sides of the wrap).....

This is where the next two pieces of tape come in. These will be needed to once again keep everything in line while doing the next 2 bindings. The middle wire must always stay in the middle....

After repeating the process of the bindings, you should end up with this. Note that the binding wraps are fairly uniform. As long as you don't crimp them too tight, they will still be adjustable (moveable). Both sides of the bail should look even after all of the adjusting is done. If you look closely, I haven't done any adjusting here. Both sides are "fairly" even, but not perfect (yet).

For the next step we use the flat nosed pliers again. Here we need to spread the wrap apart so that the cab may be inserted....

Now we can start working the wrap around the cab. The cab that I'm using for this wrap is 18mm x 25mm.....

In this pic, note that I did some adjusting on the two bindings on the sides so they are more uniform. It's starting to look like a wire wrap! ...

In this pic you can see where the one side has the long end and the other is short. The long end will be reserved for your swirls....

The short end is for your bail, here you'll use the round-nosed pliers to do the bending. I did my bend exactly 23mm from the top of the cab, or 7/8"......

Note that my wires are still in a straight line, same order as when I started....

Time for the next binding, this is where everything will start to come together. I start mine between the wires as shown because I don't crimp this binding and this will keep the binding from unwrapping. Again, these should be tight and uniform...

At the bottom, I tuck the wire through the wrap at the top of the cab and pull it through tightly. When cutting the ends off, I use the front cutters. Cut as close to the wrap as you can, but be very careful not to cut anything else. One thing that helps me is reading glasses and alot of light.

Using the front cutters (or side cutters if you're more comfortable), you can trim the ends of the loop wires to whatever length you want. I cut mine at different lengths for a desired effect.....

Next, round nosed pliers- use these to bend them however you want

I did mine like this

Nothing left now but to do the swirley thingys. A little creativity will make set your wrap apart from anyone elses. One thing that helps me is drawing pics. I use pencil and paper, and even Microsoft paint. You high-tech rednecks can even use Photoshop.

I do mine one wire at a time, keeping each wire as uniform as possible. Each step will require more tweaking....

Once you get this far, your wires will require some tweaking to look clean and even more uniform.

Time for another binding. Note that all of the wires are still in the same order. This binding is tricky, it's like sewing with needle and thread. Be careful not to kink the wire when pulling it through, just take it slow and pull tightly after each turn. Note that I wrapped a piece of tape around the ends of the wires...

It should look clean and tight, just like everything so far. Note that these don't get crimped either, so they must be tight in order to keep the wires from slipping around.....

After a little more tweaking on the swirls....

Using the flat nosed pliers, you can split up the loops.....

I trimmed these up a little for another one of my desired effects using the front cutters.....

Finally, with a little bending from the round-nosed pliers and VOILA!!!......

Nancy darlin, this one's for you

.....

.....

Like I said before, feel free to ask many questions, add remarks, techniques, ideas, pics of ideas...... Just don't throw anything at me. ;D Best of luck to anyone for this challenge, I hope that this makes it easier and answers a few mysteries as well. Next we'll learn how to custom paint a Harley.

I was trying to use the pliers to shape the part at the beginning that locks in the cab. I usually make them using my finger nails so using pliers to do this is like trying to do it for the first time. lol.

I was trying to use the pliers to shape the part at the beginning that locks in the cab. I usually make them using my finger nails so using pliers to do this is like trying to do it for the first time. lol.