|

|

Post by jakesrocks on Nov 19, 2011 23:23:55 GMT -5

Where did you get your T-slot aluminum ? I have a big hunk of 3/4" phenolic, And was thinking of routing slots in it, to inset aluminum rails level with the top of the phenolic.

I ordered the surplus center catalog. Should be in the mail on Monday, and here before the end of the week.

Still plan to build the old school single head machine too.

|

|

juzwuz

has rocks in the head

Member since April 2010

Posts: 526

|

Post by juzwuz on Nov 20, 2011 3:03:11 GMT -5

|

|

|

|

Post by jakesrocks on Nov 20, 2011 11:29:56 GMT -5

Thanks for the track links. Gonna check locally first. If I can find the stuff here, they can cut the lengths I want and I can save a little on shipping.

Gonna sit down at the drawing table today, and try to put the ideas rattling around in my skull on paper. Sure wish I had CAD.

|

|

juzwuz

has rocks in the head

Member since April 2010

Posts: 526

|

Post by juzwuz on Nov 21, 2011 2:13:41 GMT -5

Thanks for the track links. Gonna check locally first. If I can find the stuff here, they can cut the lengths I want and I can save a little on shipping. Gonna sit down at the drawing table today, and try to put the ideas rattling around in my skull on paper. Sure wish I had CAD. I like CAD for some stuff but for initial design, I just sketch things out on a piece of paper or better yet I just go to the garage and start putting things together. You can usually get Turbocad fairly cheap. I have an old version of Turbocad but I usually use my cnc software which has some built in 2D CAD or Punchcad Via for 3D. I made the last motor mount plate but I need to pick up a few washers and nuts from the hardware store tomorrow. I also wired up one of the motors and it actually worked. Still have to figure out a good way to organize the wirng so it's nice and safe. Hopefully tomorrow I'll have some pictures of the machine in it's 3-head configuration. |

|

|

|

Post by jakesrocks on Nov 21, 2011 10:03:49 GMT -5

Mornin Justin.

For the wiring you could try Radio Shack for a covered box and terminal strip. Just neatly run your wires around to the box and attach to various terminals. A large enough box could also contain your capacitors and power switch.

I don't have the pleasure of a CNC mill, but have a background in high precision sheet metal fabrication. I still have all of my measuring tools and a good drill press. Also a good collection of heave duty hole saws, counter sinks and counter bores. so should have no problem turning out motor plates and other parts. Also have half a sheet of 12 gauge aluminum sitting in my shed waiting for a project.

If I can't find extruded aluminum in my area, another option will be Unistrut. I know I can buy that in town.

Most of my projects start out as rough sketches too. Then I haul out the old T-square and triangles, and refine my drawings. Put in measurements, etc.

|

|

|

|

Post by jakesrocks on Nov 21, 2011 23:41:24 GMT -5

YaHooo! Got the aluminum rail and T-nut kit ordered. Will order the motors tomorrow. I found surplus T-slot rails in 1' sections, so won't even have to cut it.

|

|

juzwuz

has rocks in the head

Member since April 2010

Posts: 526

|

Post by juzwuz on Nov 22, 2011 2:01:13 GMT -5

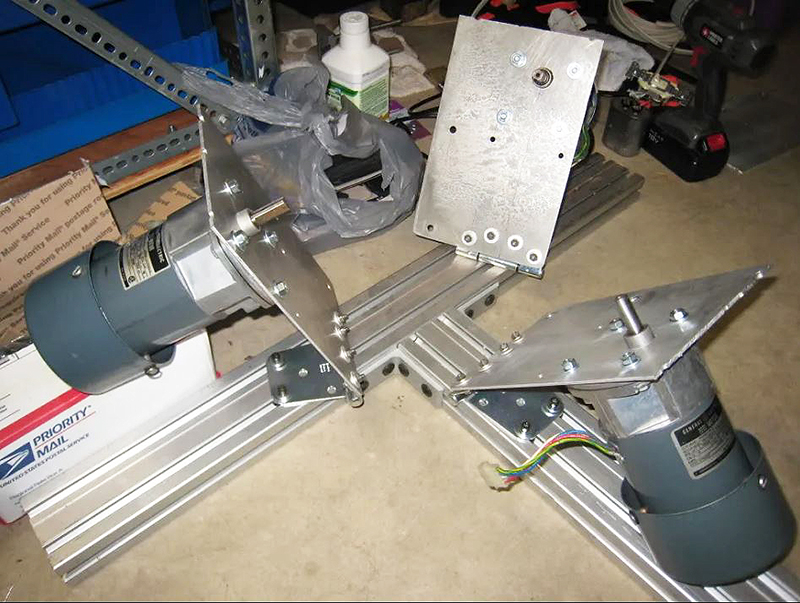

It took a while to find the 1/4"-28 fine thread nuts for the motor attachment. I still have to make 3 wire bundles and figure out the neatest way to organize the wiring. Don - thanks for the tip about terminal strips and Radio Shack. I'll check to see if they have anything useful. I might also go to the Fry's Electronics store for Black Friday deals and I can check out their selection of wiring stuff. Anyway, here's the 3-head configuration.  |

|

|

|

Post by jakesrocks on Nov 22, 2011 10:09:38 GMT -5

Looking good Jason. My aluminum rails will ship this morning, and should be here in a couple days. The motors are just 300 and odd miles south of me, so shouldn't take long to get here. Mac's Tools has a fantastic selection of nuts and bolts, so should be able to get the needed nuts there.

|

|

|

|

Post by jakesrocks on Nov 22, 2011 12:59:31 GMT -5

Well, the motors are ordered. For anyone else interested in building one of these machines, The Surplus Center still has about 200 of these gear motors. $39.95 each isn't a bad price for these. And running at 105.7 RPM's are just about perfect for sphere machines. Question for you Jason. What diameter is the bearing snout that sticks out on the mounting plate of the gear drive ? That's the only measurement they don't give in the item description. With that info, I can get a head start making the mounts while I'm waiting for the other parts to arrive. Here's the T-slot material I'll be using. www.ebay.com/itm/8020-T-Slot-Aluminum-Extrusion-15-S-3034-L-x-12-/370523163700?pt=LH_DefaultDomain_0&hash=item5644e6cc34Don |

|

juzwuz

has rocks in the head

Member since April 2010

Posts: 526

|

Post by juzwuz on Nov 23, 2011 0:44:15 GMT -5

Don, By my calipers, the bearing snout is 0.885 inch diameter. I ended up making the hole 0.95 inches diameter. I also started with a 0.25 inch hole for the bolts but I eventually used a slightly bigger drill bit so that the motor would fit nicely. I've attached a crude drawing of the motor plate. Justin  Attachments:

|

|

|

|

Post by jakesrocks on Nov 23, 2011 9:58:16 GMT -5

Thanks Jason.

I'll go today and get the material for the motor plates. Luckily The metal shop will cut it for me, so I won't have to worry about rough, out of square cuts.

Guess I'd better get the battery for my digital calipers on charge and dig out a can of layout ink. Now that I've committed myself to building this thing, I can't wait to get started. I've been retired from the sheet metal industry for about 10 years, so it will feel good to get my hands dirty again.

Don

|

|

|

|

Post by jakesrocks on Nov 23, 2011 12:26:57 GMT -5

LOL, sometimes it pays to be a packrat. I just found enough 1/4-28 aircraft grade nuts to build 3 of these machines. Also have a couple dozen 1/4-28 self locking aircraft nuts.

Jason, if you need any more of these nuts, give me a shout.

Don

|

|

jason12x12

freely admits to licking rocks

Member since October 2011

Posts: 798

|

Post by jason12x12 on Nov 23, 2011 16:49:47 GMT -5

cant wait to see it in action

|

|

|

|

Post by jakesrocks on Nov 23, 2011 17:20:59 GMT -5

Well, so much for making the motor mount plates this weekend. The damned place where I was going to get my metal closed at noon today for the thanksgiving weekend. Guess I'll have to get them first thing Monday morning. At least I got confirmation that my rails and hardware are on their way. May have them Saturday if Fedex isn't off for the weekend too.

Found some really good hinges in my basement, so at least I won't have to buy them.

|

|

sampson

starting to spend too much on rocks

Member since April 2011

Posts: 222

|

Post by sampson on Nov 23, 2011 19:16:49 GMT -5

I need another project like i need another hole in the head but everytime you post an update here i end up going through the whole thread and i think i have convinced myself to build one of these. I am also a bit of a pack rat and scrounger so i think i already have most everything to build one of these except the gear motors. Time to start digging through my piles of stuff and putting together a parts list.

Thanks for your continued updates here, i am inspired.

Sampson

|

|

|

|

Post by jakesrocks on Nov 23, 2011 19:58:30 GMT -5

Hey Sampson, if we could get enough people interested, maybe they'd give a special price on those motors. But at $136.46 for 3 gearhead motors shipping included, that's not a bad price. I'm figuring around $350.00 to build the thing. That's a lot better than the over $2,000.00 That Covington wants for one.

Don

|

|

rockhound97058

freely admits to licking rocks

Thundereggs - Oregons Official State Rock!

Thundereggs - Oregons Official State Rock!

Member since January 2006

Posts: 760

|

Post by rockhound97058 on Nov 23, 2011 21:38:06 GMT -5

|

|

|

|

Post by jakesrocks on Nov 23, 2011 23:10:03 GMT -5

Thanks for the pics Justin. Those look like the same motors Jason and I will be using. I like the idea of the slotted motor mounts with the springs on chains.

|

|

rockhound97058

freely admits to licking rocks

Thundereggs - Oregons Official State Rock!

Thundereggs - Oregons Official State Rock!

Member since January 2006

Posts: 760

|

Post by rockhound97058 on Nov 24, 2011 0:53:15 GMT -5

exactly - These motors are the same exact ones both of you guys are using. I in fact ordered 6 more motors myself. I have 2 buddies, one wants to build his own machine and the other wants me to build one for him.

The machine pictured is a machine a relative of mine designed had built and sold years ago. He was also a commercial sphere maker and had 2 to 3 machines set-up for each grit lol.

I have used this machine for years and have not had any problems. The machine I plan to build for my buddy will have a few things changed tough. One being down where the hinge is located - you see a thumb screw that screws into the upright plate - I personally would add one more on the opposite side to allow to place pressure on each side of the upright plate.

next is the grit feed - Mine is gravity, works great, however this time of year with the rains and humidity I have a heck of a time feeding 220 grit. Likes to stick, so you have to manually bump it to release more grit. The old Richardsons Models had small electric motor to dispense grit.

Also if you notice my machine has 3/4" sleeves machined over the motor shaft, that way I can screw pipe bell reducers on with no problem.

Yes the chain with springs are a must - these allow you to change the pressure on the cups as well as allows the head to flex back and forth while the machine is running.

This machine is capable of making marbles up to 6" spheres. Anything larger and it really starts to stress the motors. Marbles are always a pain in the rear to make as well. Trying to reduce the cups down to 1/4" lol

|

|

Steve

has rocks in the head

Member since June 2005

Posts: 506

|

Post by Steve on Nov 24, 2011 9:20:25 GMT -5

Jason, maybe you could run a spring from a motor mount to the rod holding your grit cup to send some shaking to your grit dispenser.

|

|