Post by TheRock on Apr 8, 2018 18:05:31 GMT -5

Well I have been Operating my New 10" BD saw now off and on for about a month prolly 16 Hrs of Total time and about an Hr and half to clean it and Iv'e cleaned it 4 Times for a total of 6 hrs. and close to 4 gal of mineral oil and a Roll of Paper towels each cleaning. So I have decided to get a Highland park Ever Clean System Mounted on it. I wrote the Company today If anyone knows a better way I am all ears. I can see why so many people prefer the water method. This oil is a dirty mess and I have spent $76.00 in Oil and towels + the time of say $10.00 and Hr X 6 hrs is $60.00 so all together $136.00 for 4 cleanings! Thanks Duke

Hi, my name is Bob aka Duke I contacted your company last week about THE EVERCLEAN SYSTEM and spoke with one of your office staff and I had some questions. So she directed me to this video.

Although her and the video link were helpful I want to run some pictures and measurements by you and what I am trying to do and accomplish. I have a Barranca Diamond 10” saw that after a short time gets extremely dirty. So much so that I Have had to change oil 4 times in about 16hrs of total use. It Takes a couple hrs to do this task and have used a total of 3 Gals of oil. A friend of mine and I have been talking on how to accomplish this.

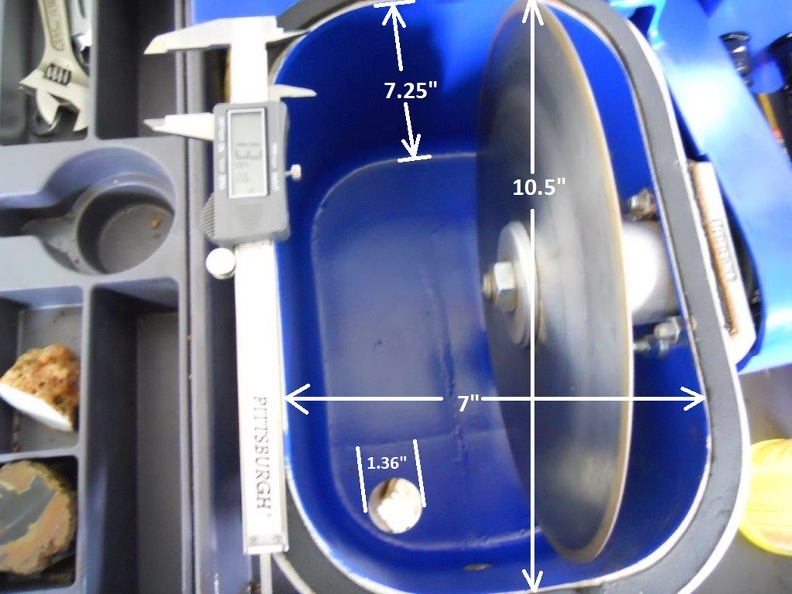

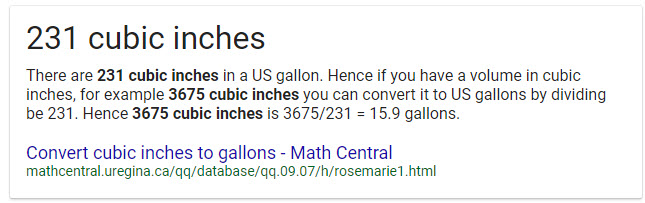

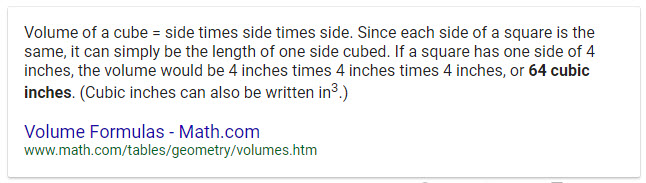

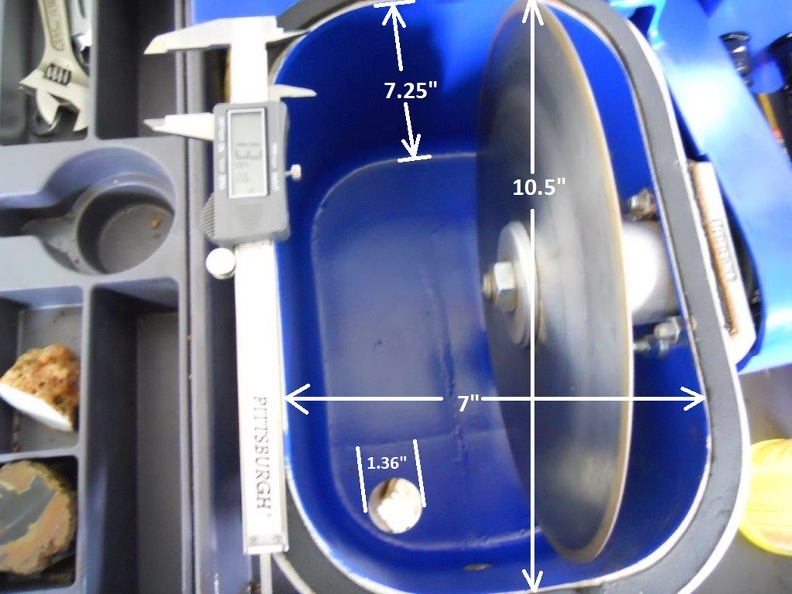

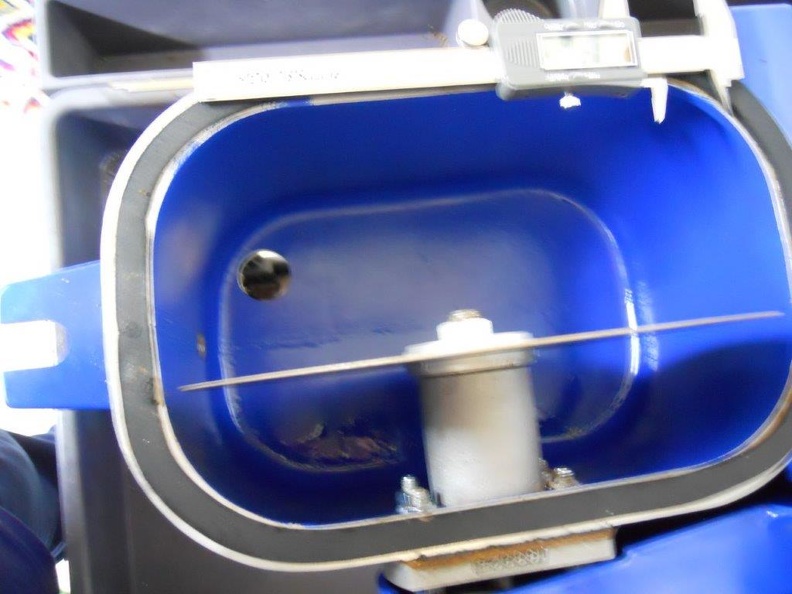

The inside tank dimensions of the BD saw is 10.5” long X 7” wide X 7.25” = 532.875 Sq Inches If the Tank were square / divided by 231= 2.30 Gals of capacity again

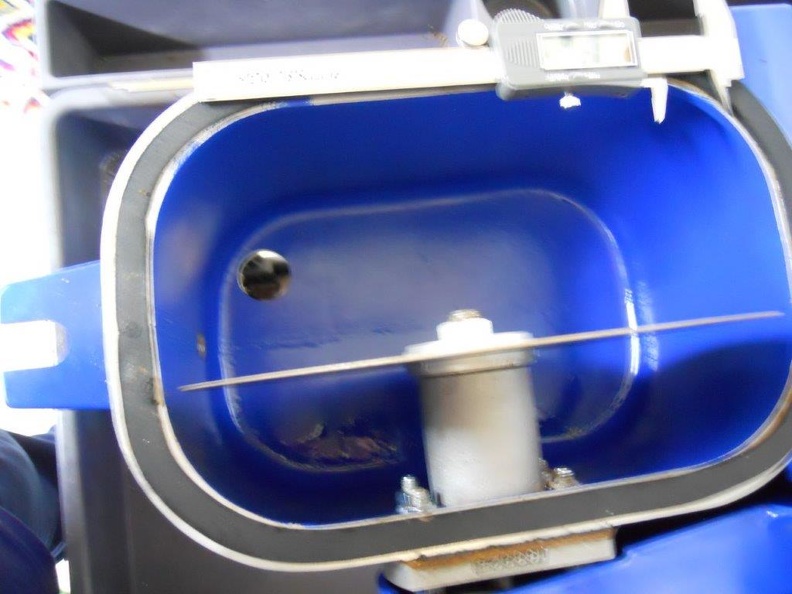

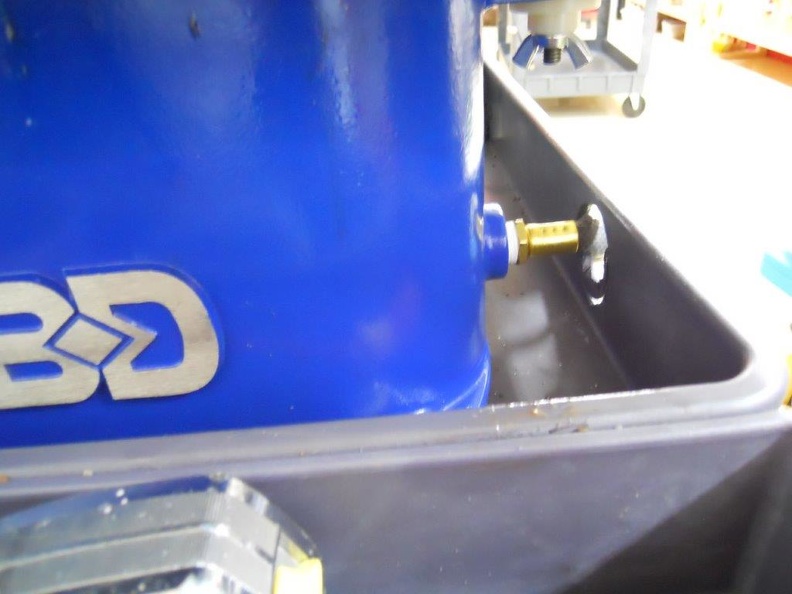

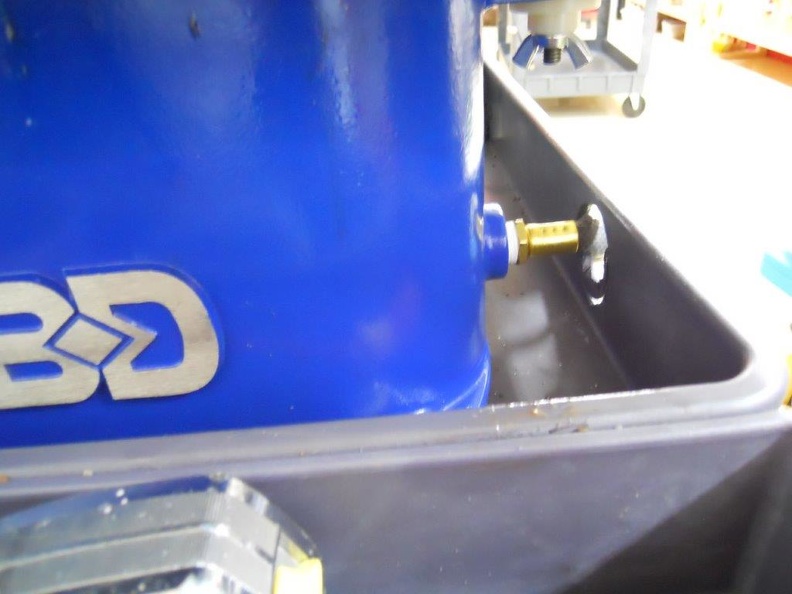

That would be if the tank was square. The Tank is probably less tha 2 Gals and I wouldn’t want it to be only about an inch and a half of mineral oil to run in the saw anyway just so the blade is about ¼” to ½” covered with oil so it can sling it up on the rock being cut so it stays lubricated. What do you think of this idea?? Since my saw is mounted on a Harbor freight Cart which is very sturdy it has a bottom shelf that can easily support my own made tank. Let me interject something here I am by trades a retired pipefitter HVAC Contrator. My skills in welding I can Tig, Mig, Arcweld, materials including Carbon, Stainless, Aluminum So I plan to make a small tank to be placed in the bottom of Cart 10X10X10 = 1000sq in / 231 = 4.329004329004329 Gal of capacity. The round drain hole you see pictured in the bottom of the saw will have an Aluminum Nipple with a brass full port Ball Valve Inline that will drain the dirty oil where it needs to go. The Part that concerns me is how to keep the proper level of lube in the saw to lubricate the blade? There is a rubber hose attached to the bottom of the saw that can be used to return the oil to the saw. In my thinking How about have two steel lines in the tank spraying on each side of the blade maybe have another in the tank of the saw churning up any debris so they get filtered? I would also like a line topside to allow clean oil to flush the dirty mud down the blade slot to keep the top clean when I am adjusting the rock. Here are some more pictures please give me your thoughts and what you think.

Thanks Bob

Hi, my name is Bob aka Duke I contacted your company last week about THE EVERCLEAN SYSTEM and spoke with one of your office staff and I had some questions. So she directed me to this video.

Although her and the video link were helpful I want to run some pictures and measurements by you and what I am trying to do and accomplish. I have a Barranca Diamond 10” saw that after a short time gets extremely dirty. So much so that I Have had to change oil 4 times in about 16hrs of total use. It Takes a couple hrs to do this task and have used a total of 3 Gals of oil. A friend of mine and I have been talking on how to accomplish this.

The inside tank dimensions of the BD saw is 10.5” long X 7” wide X 7.25” = 532.875 Sq Inches If the Tank were square / divided by 231= 2.30 Gals of capacity again

That would be if the tank was square. The Tank is probably less tha 2 Gals and I wouldn’t want it to be only about an inch and a half of mineral oil to run in the saw anyway just so the blade is about ¼” to ½” covered with oil so it can sling it up on the rock being cut so it stays lubricated. What do you think of this idea?? Since my saw is mounted on a Harbor freight Cart which is very sturdy it has a bottom shelf that can easily support my own made tank. Let me interject something here I am by trades a retired pipefitter HVAC Contrator. My skills in welding I can Tig, Mig, Arcweld, materials including Carbon, Stainless, Aluminum So I plan to make a small tank to be placed in the bottom of Cart 10X10X10 = 1000sq in / 231 = 4.329004329004329 Gal of capacity. The round drain hole you see pictured in the bottom of the saw will have an Aluminum Nipple with a brass full port Ball Valve Inline that will drain the dirty oil where it needs to go. The Part that concerns me is how to keep the proper level of lube in the saw to lubricate the blade? There is a rubber hose attached to the bottom of the saw that can be used to return the oil to the saw. In my thinking How about have two steel lines in the tank spraying on each side of the blade maybe have another in the tank of the saw churning up any debris so they get filtered? I would also like a line topside to allow clean oil to flush the dirty mud down the blade slot to keep the top clean when I am adjusting the rock. Here are some more pictures please give me your thoughts and what you think.

Thanks Bob

All I know it seems like a short time and the Sediment on top of the table looks like pancake batter consistency If you don't clean the top good when you open the BD it runs all over the motor! I made a mistake when I bolted unit down to the cart cause the saw needs a Nipple Installed so it goes through the Cart so saw can be drained into a bucket or whatever. As far as the blade thickness I will Mic it tomorrow. I run a little more oil than what it says or is recommended because it make a Big Difference when you use an extra pint or so of oil cause it drips nicely keeping the blade and plenty of oil on the stone and it cuts better. I can hear the difference cause the saw is quieter and runs cooler.

All I know it seems like a short time and the Sediment on top of the table looks like pancake batter consistency If you don't clean the top good when you open the BD it runs all over the motor! I made a mistake when I bolted unit down to the cart cause the saw needs a Nipple Installed so it goes through the Cart so saw can be drained into a bucket or whatever. As far as the blade thickness I will Mic it tomorrow. I run a little more oil than what it says or is recommended because it make a Big Difference when you use an extra pint or so of oil cause it drips nicely keeping the blade and plenty of oil on the stone and it cuts better. I can hear the difference cause the saw is quieter and runs cooler.  ~Duke

~Duke That ain't much of a real saw more like a TOY!

That ain't much of a real saw more like a TOY!  My next saw would be a 24" that I would cut to the material to the size that the BD could handle then I would switch to the QEP 7" or the HF 4" both of those saws will Use GEM LUBE w/ Water. I'm Itching for a Fab project Welding is in my veins.

My next saw would be a 24" that I would cut to the material to the size that the BD could handle then I would switch to the QEP 7" or the HF 4" both of those saws will Use GEM LUBE w/ Water. I'm Itching for a Fab project Welding is in my veins.