|

|

Post by tandl on Feb 17, 2012 16:04:42 GMT -5

Looking purty cool

|

|

Don

Cave Dweller  He wants you too, Malachi.

He wants you too, Malachi.

Member since December 2009

Posts: 2,616

|

Post by Don on Feb 17, 2012 16:23:17 GMT -5

outstanding. You're machining this out of stainless steel? You know, a stone with native copper running through it would be killer scales.

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Feb 23, 2012 11:24:28 GMT -5

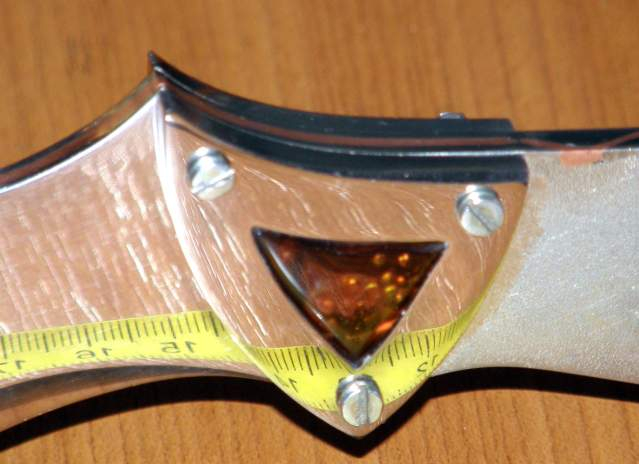

Hello, again. Here's a new update. It may not seem much, but at this stage a lot of detail work is needed to fit the pieces together. Don, your idea about using native copper stone sounded very good, thanks a lot. Your idea reminded me about a slab given to me by Karen (karenfh). Thanks a lot, Karen! From this slab I could extract a cab big enough to include in a bolster. So, even if initially I planned to put a cab only on the front-left bolster, I also cut a window and a matching cab on the front right one. Here it is:  This native copper cab is not polished. It would be flushed to the bolster's level and then polished. For the other bolster, I had in plan a special stone: a fire agate. For this reason I contacted Christopher (christopherl) and he was very helpful in choosing a piece to fit my project. I chose one not only big enough for the triangular cab, but also with a "cosmic" pattern, kinda matching the meteorite theme. Here it is, the cab roughly cut, firstly pictured dry...  ... and then wet:  Then, slowly bringing it to the window's shape, until it fit inside:  (What might look like scratches on the cab are in fact the reflections of the wood grain of the table.) I was polishing this cab, as I plan not to flush it to the bolster level (I am affraid of loosing the fire inside the stone). Christopher, thank you for the top grade fire agate you gave to me. It was a pleasure to work with it. Very hard and solid stone. The scales are next, For the moment, I only made the copper separators. These would go in between the two stones which I would use for each scale.   Thank you for looking, Adrian |

|

|

|

Post by FrogAndBearCreations on Feb 23, 2012 11:30:53 GMT -5

Beautiful progress, thats is some knife!

|

|

|

|

Post by Toad on Feb 23, 2012 12:22:32 GMT -5

Looking great as usual. More fantasical with every update.

|

|

|

|

Post by Hard Rock Cafe on Feb 23, 2012 12:57:40 GMT -5

I continue to be amazed by your creativity and craftsmanship. Well done!

Chuck

|

|

|

|

Post by christopherl1234 on Feb 23, 2012 15:24:37 GMT -5

Adrian, couldn't you grind the back of the Fire Agate to bring it down level with the bolster?

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Feb 23, 2012 15:37:39 GMT -5

Adrian, couldn't you grind the back of the Fire Agate to bring it down level with the bolster? No, Christopher, because the face of the rough was slightly domed (curved) and I was affraid to flatten it (for the reason told above - not to loose the fire which seems to be pretty close under that curved surface). Adrian |

|

SteveHolmes

fully equipped rock polisher

Member since July 2009

Posts: 1,900

|

Post by SteveHolmes on Feb 23, 2012 19:19:04 GMT -5

SPECTACULAR Adrian! That's to say the least. Your workmanship is amazing.

steve

|

|

|

|

Post by kk on Feb 23, 2012 20:21:15 GMT -5

Christopher, Adrian: I think it looks better that way anyway. As the knife will never be actually used there is no problem with the space between metal and stone.

Wonderful progress, the FA looks fantastic and I love the color contrast.

|

|

|

|

Post by Roller on Feb 23, 2012 23:00:38 GMT -5

phweeew phweew ..lol i just whistled at a knife ..

|

|

dbrealityrocks

fully equipped rock polisher

Member since February 2010

Posts: 1,084

|

Post by dbrealityrocks on Feb 24, 2012 8:50:57 GMT -5

WOW simply amazing!!! Some of the finest work I've seen on here!

|

|

|

|

Post by roy on Feb 24, 2012 10:29:23 GMT -5

dang adrian this is comming along well cant wait to see what you use for the handle

|

|

Tex

starting to shine!

Member since December 2011

Posts: 27

|

Post by Tex on Feb 24, 2012 14:25:54 GMT -5

spectacular one of most amazing things I've seen

|

|

|

|

Post by helens on Feb 24, 2012 19:49:34 GMT -5

It is astonishing. With a BIG fire agate as a centerpoint, a meteor for a point, I can't wait to see what crazy stone you use for the handle! This knife should be on display somewhere when finished... with a giant poster behind the glass case showing the step by step photos of its making. What an accomplishment!!

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Feb 25, 2012 8:07:00 GMT -5

... As the knife will never be actually used... What makes you think that, Kurt? I plan to use it as the Chritmas Tree chopper and, in between, to use it in the kitchen as the main butcher knife ;D Just kidding, of course it won't be used! |

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Feb 26, 2012 2:07:42 GMT -5

Hello everyone, I finished the metal work and prepared the handle to host the stone scales. I riveted the front bolsters. Bearing in mind the slightly domed fire agate cab in the left bolster, I wanted to add some round head rivets here to match the domed cab and especially protect it when the knife would be put this side down. But I didn't have anything but some copper thick electric wire, so this is how I made those rivets myself: I cut a groove some 1 inch long in two metal sheets. When those two metal sheets were sandwiched together, the grooves formed a sort of mold for the wire to stay in tight:  Then, using this cup shaped snap...  I shaped the rounded head of the rivets by gently hammering:  Not all the rivets I made this way had a well centered head. I didn't pay attention to this detail and used one of those out-of-center rivets. It was only when the riveting was completed when I noticed the hole was still visible:  So I removed this rivet and replaced it with another one, better centered:  I also flushed the upper spine of the blade with the freshly riveted front bolsters and I glued the copper strip separators (using two parts epoxy for metals). So, this is how the handle looks now, waiting for the stone scales:  Thank you for looking, Adrian |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Feb 26, 2012 10:17:30 GMT -5

I am having trouble coming up with the words that would express my feeling about your work. Master artisan is the only thing that comes to mind. Thank you so much for sharing your work. The only bad thing is that I will never get to see it and hold it in my hand. A true masterpiece.

Jim

|

|

|

|

Post by helens on Feb 26, 2012 18:50:59 GMT -5

I agree. I LOVE looking at the pictures, but sometimes just don't know what to say. His work is just superb.

|

|

TByrd

fully equipped rock polisher

Have you performed your random act of kindness?

Have you performed your random act of kindness?

Member since December 2010

Posts: 1,350

|

Post by TByrd on Feb 27, 2012 1:16:12 GMT -5

What an awesome project! I love seeing the updates. You really are talented. I hope that I can learn something from you. Thank you so much.

|

|