Post by adrian65 on Jan 11, 2012 12:08:01 GMT -5

Hello everyone!

These days I started a project I had in mind since last November.

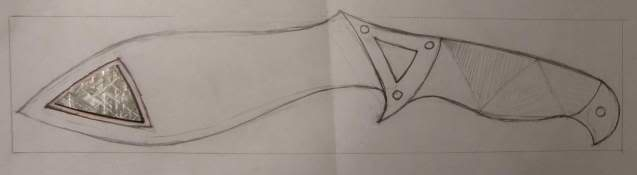

It all got started when I visited Mineralientage Munchen, where I found some meteorite slabs. I firstly intended to buy a slab to make a knife entirely out of it, but it would had been costing a real fortune. So I limited to a small triangular slabbet, which I planned to embed in a stainless steel knife.

Here is the slabbet (as small as you see it, it costed 20 euros, discount included) together with the sketch of the knife:

These days I also found some stainless steel strip (5 mm thick) so my project could really start.

Firstly, cutting and gross grinding the contour:

Then, smooth grinding of the knife's contour and then cutting the window for the meteorite piece.

Firstly, drilling holes inside window's contour:

Then, using a whole collection of files...

... I gradually brought the hollow to the meteorite's shape...

.

... until it fitted tight.

Given the difference between the meteorite slab (3 mm) and the stainless steel sheet (5mm), I split this difference in two by centering the slab and I chamfered the remaining edges, as you see here:

For the moment, the slab stays there just by friction, but of course I will solder it in position.

About the final finish of this slab, I balance between the two options:

1. Leaving it as it is, uncovered and slightly sunk compared to the rest of the surface of the blade.

2. Covering the meteorite slab with a thin layer of transparent epoxy., which I would polish together with the stainless steel blade.

I have pros an cons for each of the two options. On one side, I'd like to protect the meteorite from rusting and provide a smooth surface all across the blade. But on the other side, I am concerned about the behaviour in time of this epoxy layer and I somehow think that on a knife's blade any other material than metal is improper.

Any idea/opinion related to my dilemma is very welcome.

Grinding the blade to the meteorite's thickness is not an option, because once polished the interesting striped structure of the meteorite (called Wiedmanstaetten) would disappear and would only reveal with a chemical (acid) treatment which is beyond my skills and possibilities.

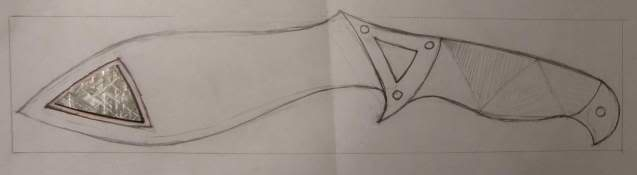

So, all in all, this is how the knife looks for the moment:

The total length of the knife is 310 mm.

Thank you for looking and for any advices,

Adrian

These days I started a project I had in mind since last November.

It all got started when I visited Mineralientage Munchen, where I found some meteorite slabs. I firstly intended to buy a slab to make a knife entirely out of it, but it would had been costing a real fortune. So I limited to a small triangular slabbet, which I planned to embed in a stainless steel knife.

Here is the slabbet (as small as you see it, it costed 20 euros, discount included) together with the sketch of the knife:

These days I also found some stainless steel strip (5 mm thick) so my project could really start.

Firstly, cutting and gross grinding the contour:

Then, smooth grinding of the knife's contour and then cutting the window for the meteorite piece.

Firstly, drilling holes inside window's contour:

Then, using a whole collection of files...

... I gradually brought the hollow to the meteorite's shape...

.

... until it fitted tight.

Given the difference between the meteorite slab (3 mm) and the stainless steel sheet (5mm), I split this difference in two by centering the slab and I chamfered the remaining edges, as you see here:

For the moment, the slab stays there just by friction, but of course I will solder it in position.

About the final finish of this slab, I balance between the two options:

1. Leaving it as it is, uncovered and slightly sunk compared to the rest of the surface of the blade.

2. Covering the meteorite slab with a thin layer of transparent epoxy., which I would polish together with the stainless steel blade.

I have pros an cons for each of the two options. On one side, I'd like to protect the meteorite from rusting and provide a smooth surface all across the blade. But on the other side, I am concerned about the behaviour in time of this epoxy layer and I somehow think that on a knife's blade any other material than metal is improper.

Any idea/opinion related to my dilemma is very welcome.

Grinding the blade to the meteorite's thickness is not an option, because once polished the interesting striped structure of the meteorite (called Wiedmanstaetten) would disappear and would only reveal with a chemical (acid) treatment which is beyond my skills and possibilities.

So, all in all, this is how the knife looks for the moment:

The total length of the knife is 310 mm.

Thank you for looking and for any advices,

Adrian